A4 Mk1

|

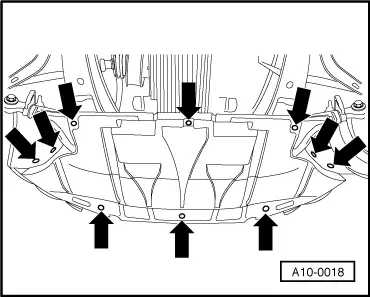

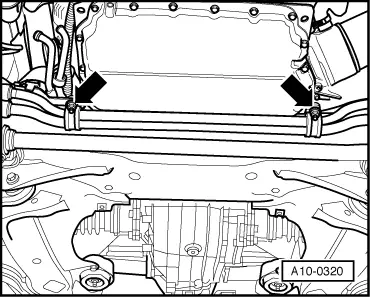

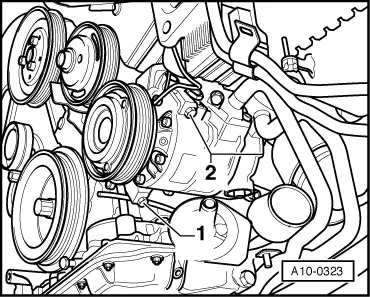

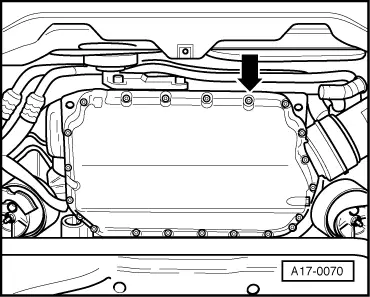

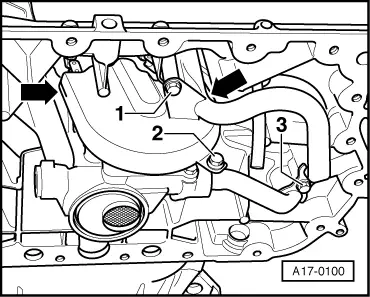

Removing and installing parts of lubrication system

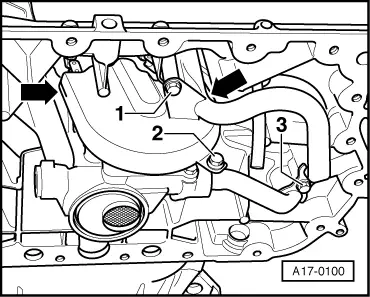

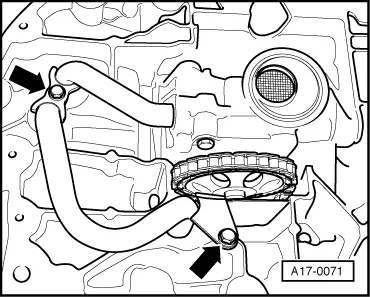

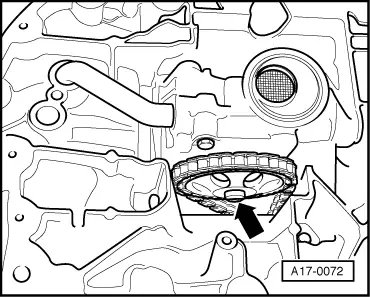

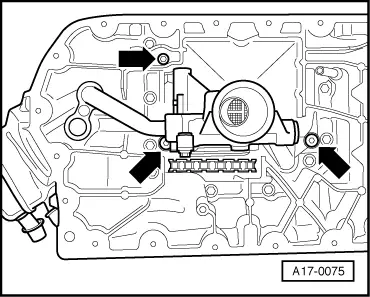

Removing and installing oil pump

|

|

|

=> General body repairs; Repair group 63; Front bumper; Removing and installing front bumper

=> General body repairs; Repair group 50; Removing and installing lock carrier; Lock carrier service position |

|

|

|

|

|

|

Warning

Do not open air conditioner refrigerant circuit.

Notes:

Note: Use a separate container to collect the engine oil. |

|

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

Installing: Install in the opposite order to removing. When installing, note the following points:

|

|

|||||||||||||||||||||||||

Notes:

Note: Do not use any adhesive or sealant.

Oil system capacity: => Maintenance manual

=> General body repairs, Exterior; Repair Group 50; => Front body; Lock carrier service position

Tightening torques

| |||||||||||||||||||||||||