A4 Mk1

| Removing engine |

| Special tools and workshop equipment required |

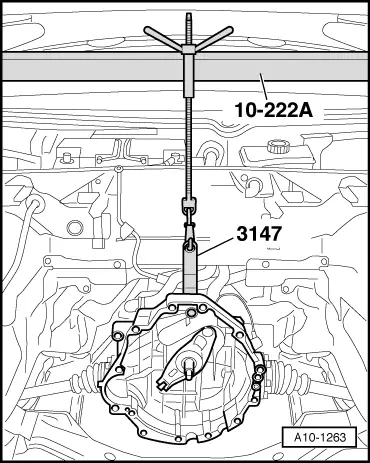

| t | Support bracket -10-222 A- |

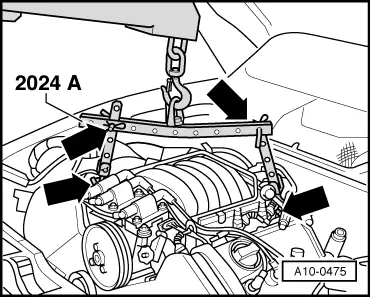

| t | Lifting tackle -2024 A- |

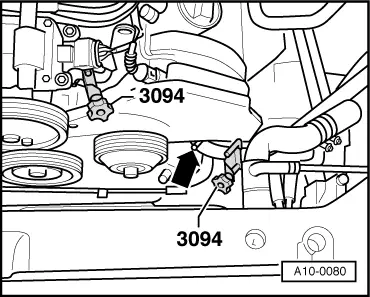

| t | Hose clamps for hoses up to 25 mm Ø -3094- |

| t | Gearbox support -3147- |

| t | Workshop hoist -V.A.G 1202 A- or -VAS 6100- |

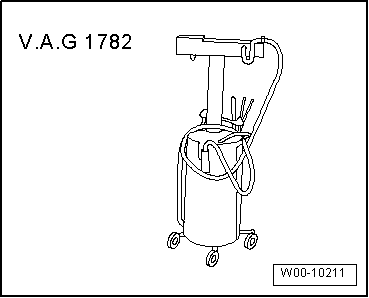

| t | Drip tray for workshop hoist -VAS 6208- or -V.A.G 1306- |

| t | Locking pin -3204- |

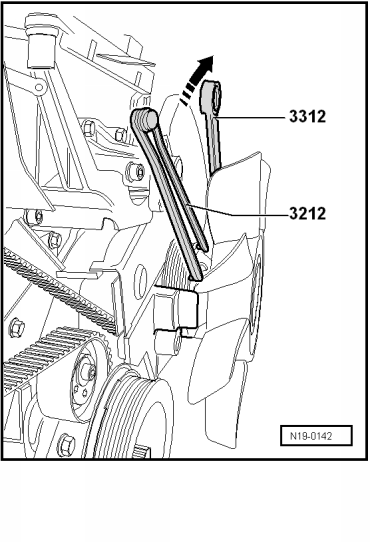

| t | 2-hole pin wrench -3212- |

| t | Open-end spanner -3312- |

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

Note

Note

|

|

|

|

Caution

Caution WARNING

WARNING