A4 Mk1

| Removing and installing front sealing flange - “engine generation III” |

| Special tools and workshop equipment required |

| t | Fitting sleeve -3202/1- from fitting sleeves -3202- |

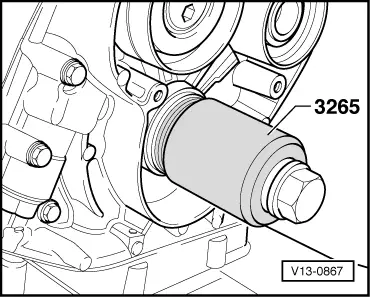

| t | Fitting sleeve -3265- |

| t | Used oil collection and extraction unit -V.A.G 1782- |

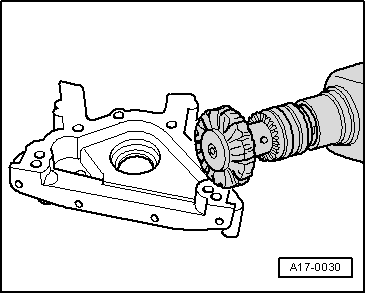

| t | Electric drill with plastic brush attachment |

| t | Safety goggles |

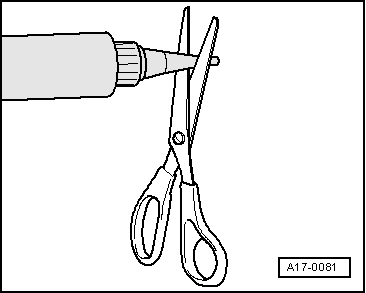

| t | Sealant → Parts catalogue |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

Note

Note

|

|

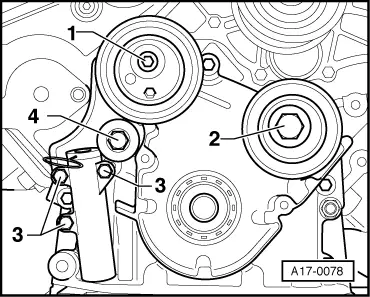

| Component | Nm | ||||||

| Front sealing flange to cylinder block | M6 | 10 | |||||

| M8 | 30 | ||||||

| Sealing flange (front) to sump (top section) | M6 | 10 | |||||

| M7 | 16 | ||||||

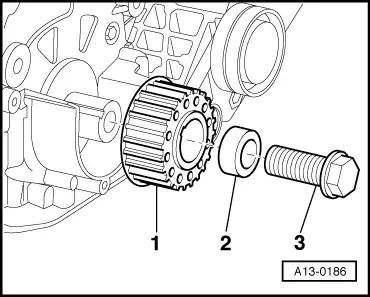

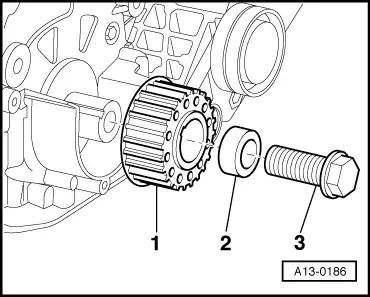

| Toothed belt sprocket to crankshaft | 200 + 180° 1)2) | ||||||

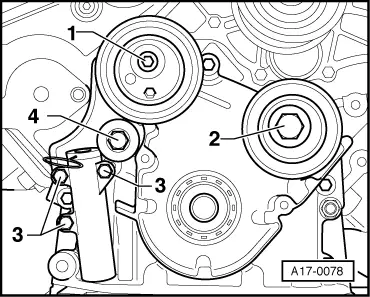

| Toothed belt tensioning roller to sealing flange (front) | 42 | ||||||

| Tensioner to sealing flange (front) | 10 | ||||||

| Tensioning lever to sealing flange (front) | 22 | ||||||

| Tensioning roller to sealing flange (front) | 22 | ||||||

| Idler roller to sealing flange (front) | 45 | ||||||

| |||||||

WARNING

WARNING