| –

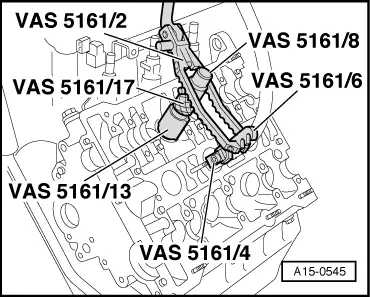

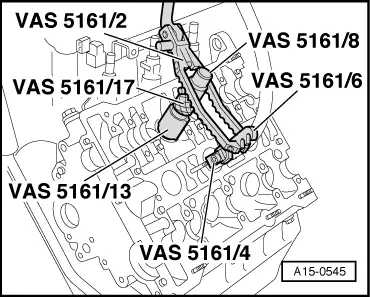

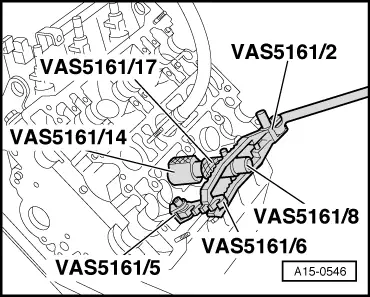

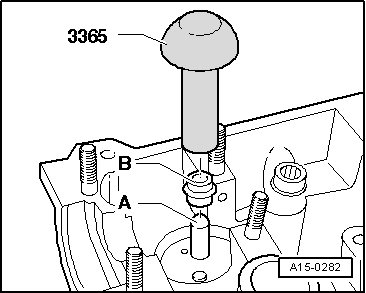

| Screw snap-in device -VAS 5161/6- with interlocking fork -VAS 5161/4- onto stud on cylinder head. |

| –

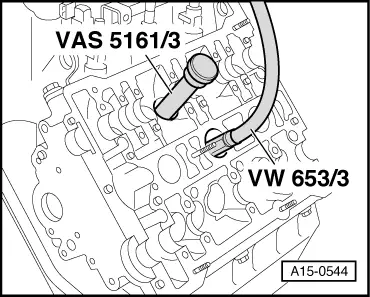

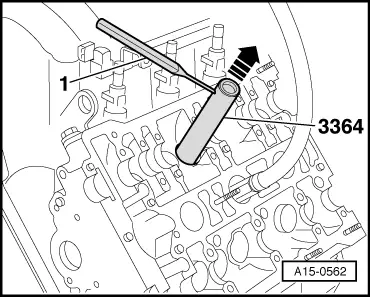

| Push guide bush -VAS 5161/13- as far as it will go into bucket tappet guide for valve to be removed. |

| l

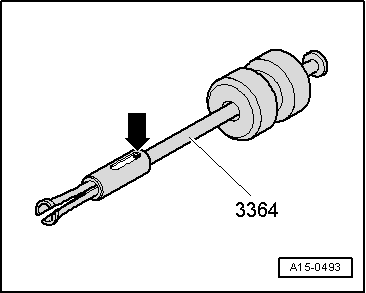

| Installation position: knurled surfaces face perpendicular to direction of travel. |

| –

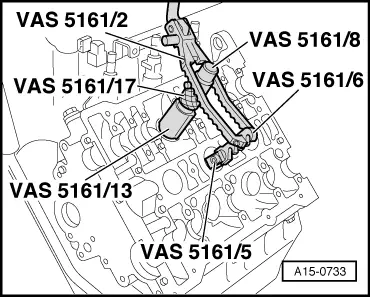

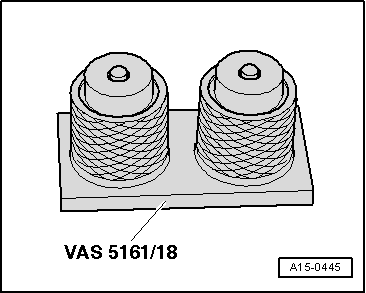

| Slide knurled spacer ring -VAS 5161/17- onto assembly cartridge -VAS 5161/8-. |

| –

| Insert assembly cartridge into guide bush. |

| –

| Attach pressure fork -VAS 5161/2- to snap-in device -VAS 5161/6- and push assembly cartridge down. |

| –

| At the same time, turn knurled screw of assembly cartridge clockwise until tips engage in valve cotters. |

| –

| Move knurled screw back and forth slightly; the valve cotters are thus forced apart and taken up by the cartridge. |

| –

| Release the pressure fork. |

| –

| Take off assembly cartridge with knurled spacer ring. |

| –

| Remove guide bush, valve spring plate and valve spring. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note