A4 Mk1

| Pistons and conrods - exploded view of components |

Note

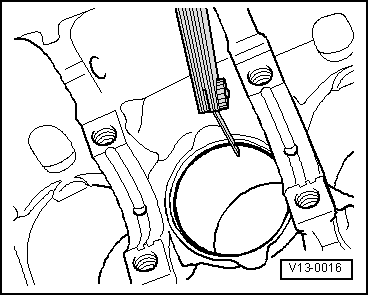

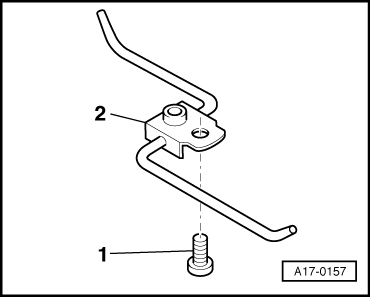

Note| Oil spray jet for piston cooling → Fig.. |

| 1 - | Conrod bolt, 30 Nm + 90° (1/4 turn) further |

| q | Renew |

| q | Lubricate threads and contact surface |

| q | To measure radial clearance, tighten to 30 Nm but do not turn further |

| 2 - | Conrod bearing cap |

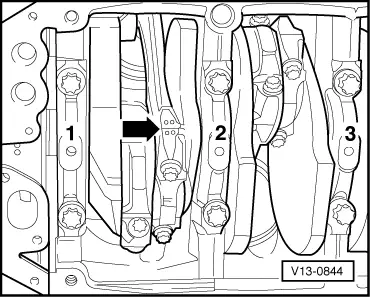

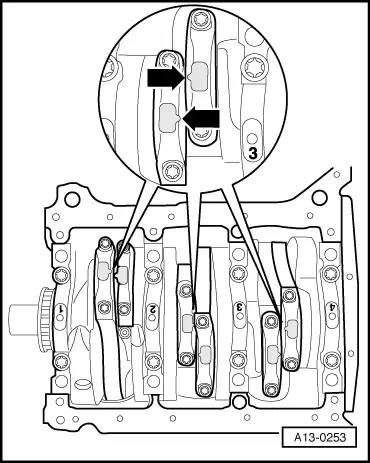

| q | Note installation position: split contact surfaces on side of conrod must be in alignment -B- |

| 3 - | Bearing shell |

| q | Note installation position |

| q | Do not interchange used bearing shells (mark positions) |

| q | Note type: upper bearing shell (closest to piston) is made of more wear-resistant material. Distinguishing feature on new bearing shells: black marking on contact surface near separating point |

| q | Check that it is securely seated |

| q | Measuring radial clearance → Chapter |

| q | To measure radial clearance, tighten bolts → Item to 30 Nm but do not turn further |

| 4 - | Conrod |

| q | Only renew as a complete set |

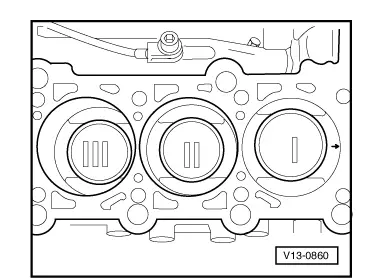

| q | Mark cylinder allocation -A- → Fig. |

| q | Note when fitting bearing cap: split contact surfaces on side of conrod must be in alignment -B- |

| q | Installation position of conrod pairs → Fig. |

| 5 - | Circlip |

| 6 - | Piston pin |

| q | If difficult to move, heat piston to approx. 60 °C |

| q | Remove and install using drift -VW 222 A- |

| 7 - | Piston |

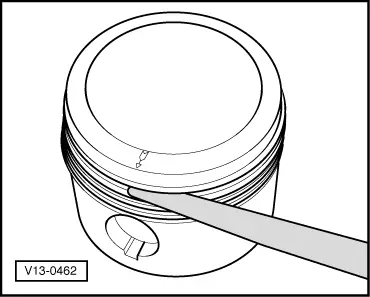

| q | Mark installation position and cylinder number → Fig. |

| q | Arrow on piston crown points to pulley end |

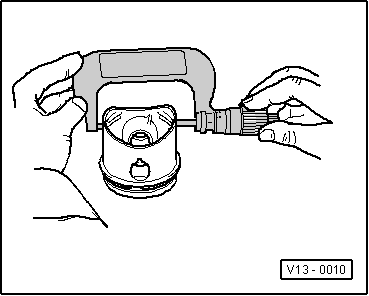

| q | Checking → Fig. |

| q | Install using piston ring clamp |

| q | Piston and cylinder dimensions → Chapter |

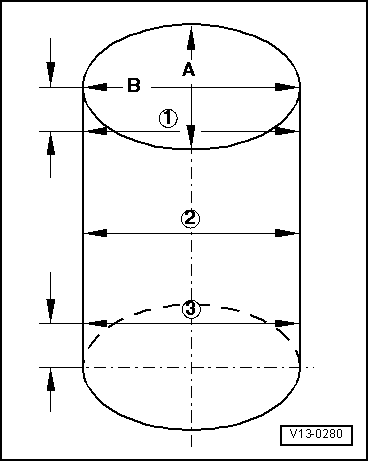

| q | Checking cylinder bore → Fig. |

| 8 - | Piston rings |

| q | Offset gaps by 120° |

| q | Use piston ring pliers to remove and install |

| q | “TOP” must face towards piston crown |

| q | Checking ring gap → Fig. |

| q | Checking ring-to-groove clearance → Fig. |

| Piston ring Dimensions in mm | New | Wear limit |

| 1st compression ring | 0.35 … 0.50 | 1.0 |

| 2nd compression ring | 0.50 … 0.70 | 1.4 |

| Oil scraper ring | 0.25 … 0.50 | 0.8 |

|

|

| Piston ring Dimensions in mm | New | Wear limit |

| Compression rings | 0.02 … 0.08 | 0.10 |

| Oil scraper ring | 0.02 … 0.08 | 0.10 |

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|