| –

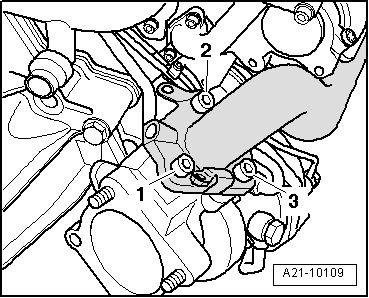

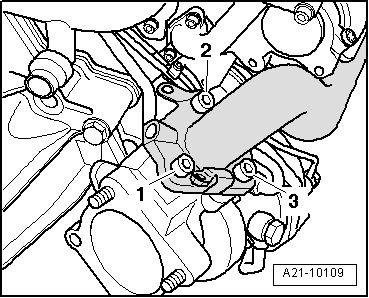

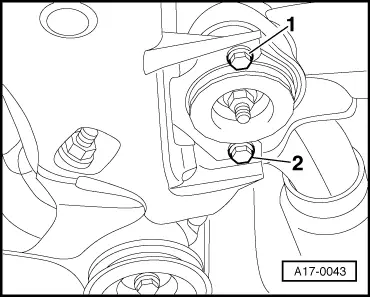

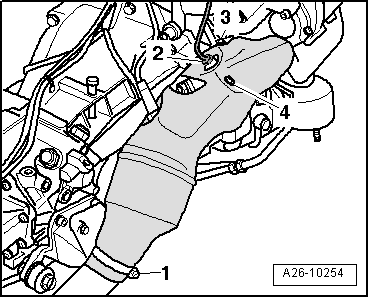

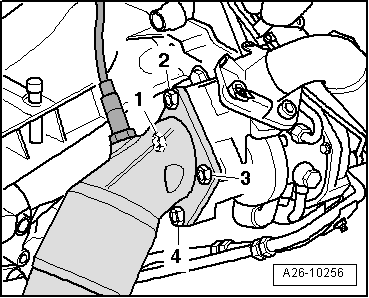

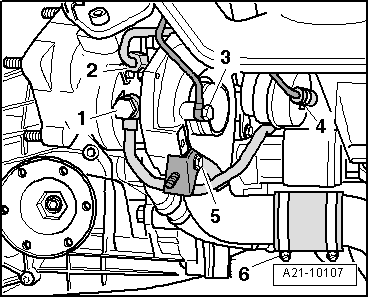

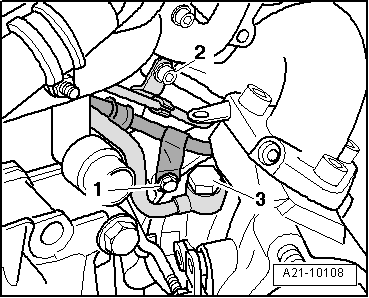

| Remove bolts -1 … 3- and take out turbocharger. |

| Installation is carried out in the reverse order; note the following: |

Note | t

| Renew gaskets, seals, O-rings and self-locking nuts. |

| t

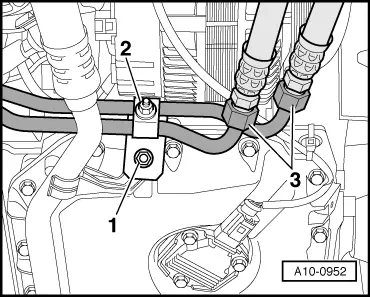

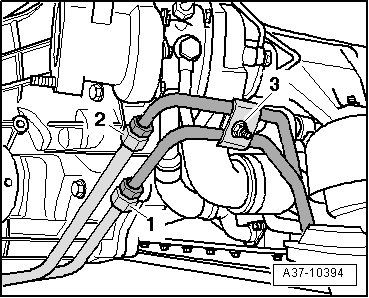

| Fill turbocharger with engine oil at connection for oil supply pipe. |

| t

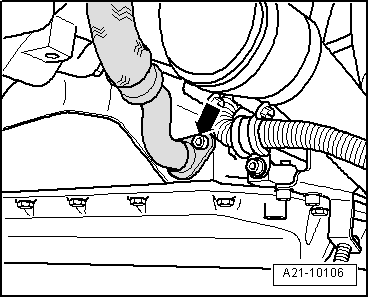

| Hose connections and hoses for charge air system must be free of oil and grease before assembly. |

| t

| Secure all hose connections with the correct type of hose clips (same as original equipment) → Parts catalogue. |

| t

| Charge air system must be free of leaks. |

| t

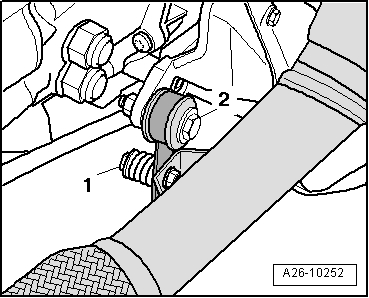

| Fit all heat insulation sleeves in the original position when installing. |

| t

| Fit all cable ties in the original positions when installing. |

| –

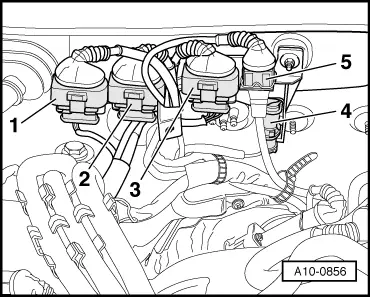

| Install exhaust gas temperature sender 1 -G235- → Chapter. |

| –

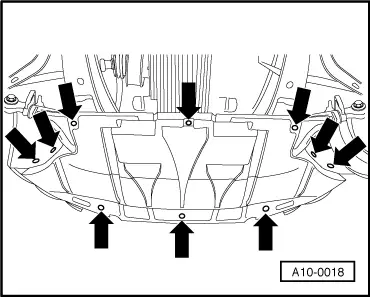

| Install front exhaust pipe (right-side) with starter and main catalytic converter → Chapter. |

| –

| Fill up with engine oil and check oil level → Chapter. |

Note | After installing turbocharger, allow engine to idle for approx. 1 minute and do not rev up immediately to ensure turbocharger is supplied with oil. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note Note

Note

Note

Note Note

Note