A4 Mk1

|

Fuel supply system - four-wheel drive

Removing and installing fuel delivery unit - vehicles with 6-cylinder turbo engine

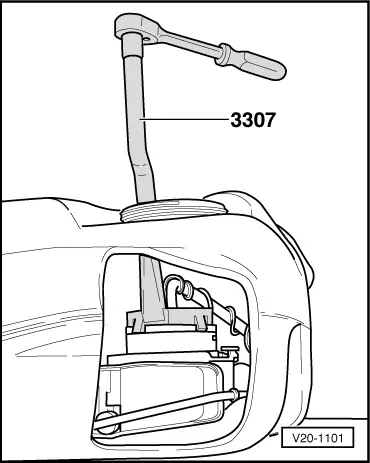

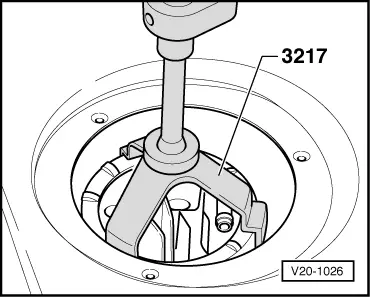

Observe safety precautions Observe rules for cleanliness Special tools, testers and auxiliary items

Removing

Note: The fuel tank must not be more than 1/3 full.

|

|

|

Warning!

Fuel system is under pressure! Before opening the system place a cloth around the connection. Then release pressure by carefully loosening the connection.

|

|

|

|

|

|

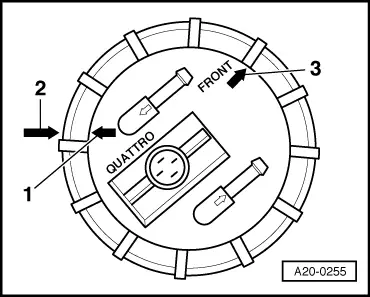

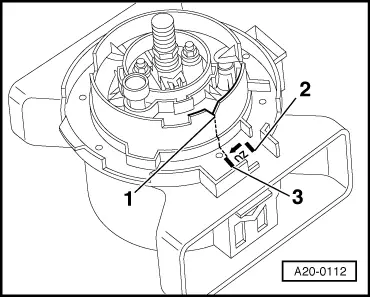

Note: Baffle housing is shown without fuel tank for a clearer illustration. |

|

|

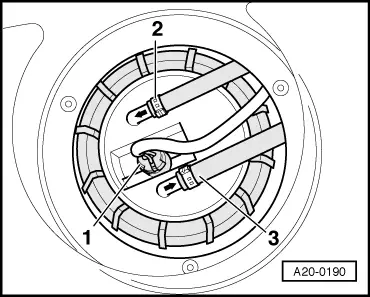

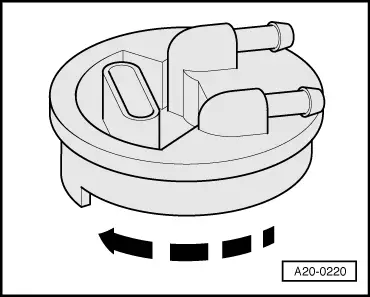

Note: Lubricate O-rings with fuel or other lubricant.

Note: Lubricate the flange seal with fuel before fitting. |

|

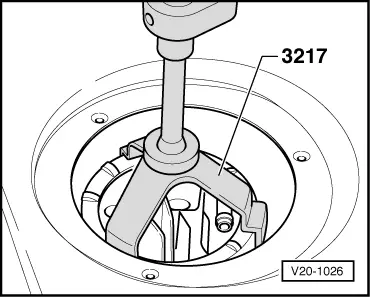

|||||||

Note: Ensure that fuel pipes are securely seated.

=> Radio operating instructions

Tightening torque

| |||||||