A4 Mk1

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

|||||||||||||||||||||||||||||||||||

Note: The engine control unit converts and displays the voltage readings from the angle senders as percentages of 5 V. (A 5 Volt supply corresponds to 100 %).

Percentage displayed in zone 1 should rise evenly. The tolerance range from 3...93 % is not fully utilised. Percentage displayed in zone 2 should fall evenly. The tolerance range from 97...3 % is not fully utilised. If the displays are not as described:

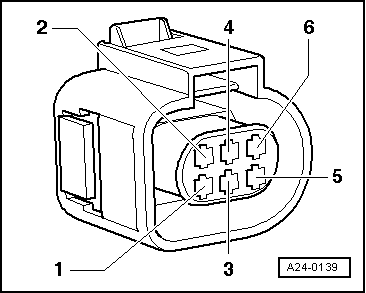

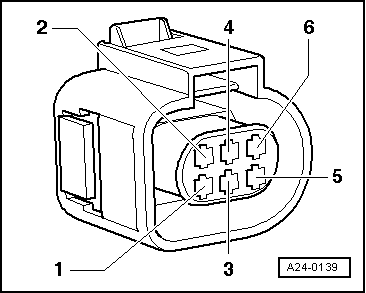

Pay particular attention to connectors, which may be loose, not properly engaged or corroded. => Current Flow Diagrams, Electrical Fault-Finding and Fitting Locations

Notes:

Checking the voltage supply to the throttle valve control part. | ||||||||||||||||||||||||||||||||||||

|

|||||||

If specifications are not attained, also check the signal and activation lines of the throttle valve actuator => Page 24-161. If specifications are not attained: Check wiring between engine control unit and throttle valve control part Checking wiring |

|

||||||||||||||

The following wiring connections are to be checked for open circuits and/or short to positive or negative.

If no wiring fault is detected:

|