-

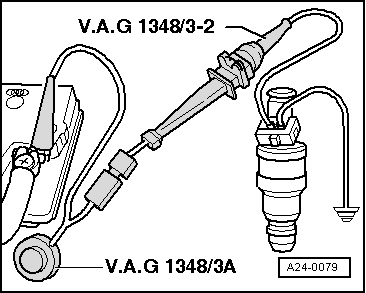

‒ → Connect one of the injector contacts to engine earth using test cable and crocodile clamp from V.A.G 1594.

-

‒ Connect second injector contact to positive using remote control V.A.G 1348/3 A, adapter cable V.A.G 1348/3-2 and auxiliary cable.

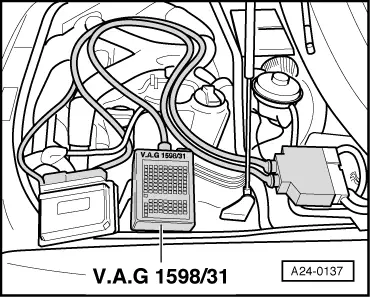

Ensure that test box is inside the vehicle.

-

‒ Bridge contacts 1 and 65 on the test box using test leads from adapter set V.A.G 1594 (this creates an earth connection to one side of the fuel pump relay coil).

The fuel pump should run.

-

‒ Activate the V.A.G 1348/3 A remote control for 30 seconds.

-

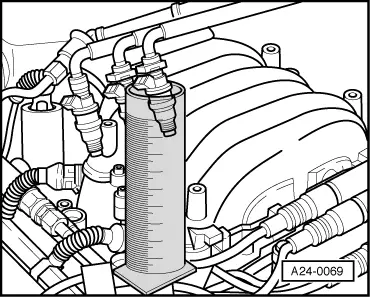

‒ Once all three injectors of a cylinder bank have been actuated, place the three measuring glasses on a flat surface.

- Specification per injector: 135...165 ml

-

‒ If measured values for one or more injectors are outside tolerance, switch off fuel pump (switch off ignition) and replace defective injector => Page 24-58.

-

‒ Repeat the check on injectors of second cylinder bank.

-

‒ If the measured values for all the injectors are outside the tolerance range, check the fuel pressure => Page 24-40.

Note:

When checking the injection quantity, also check the spray pattern. The spray pattern should be the same for all the injectors.

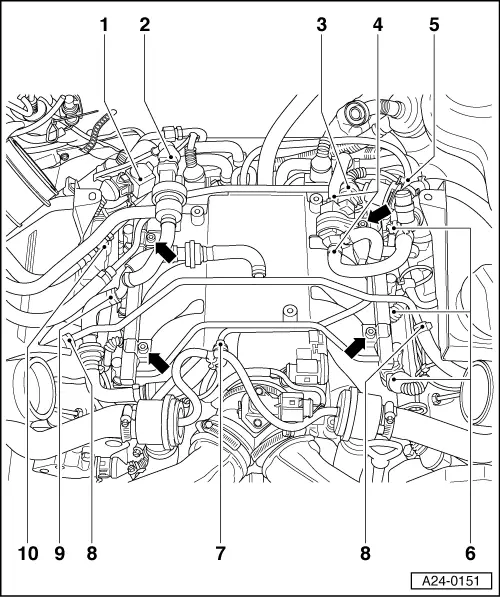

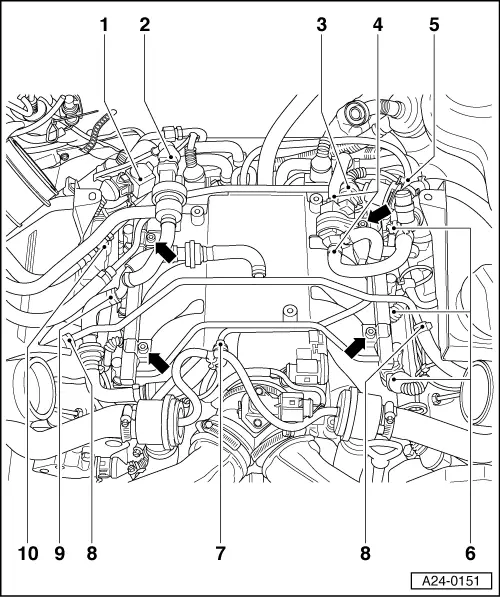

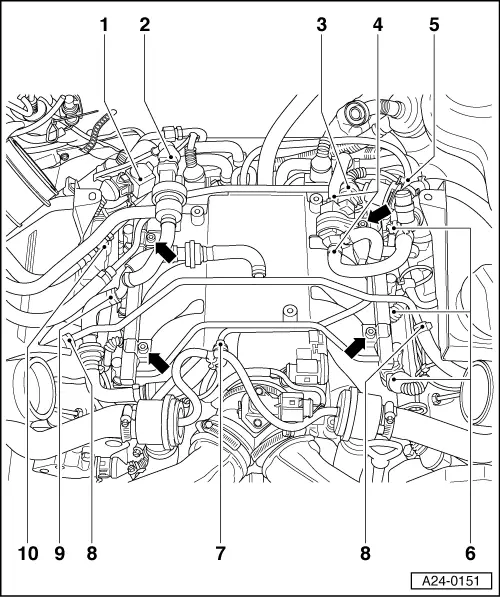

Notes on installation of fuel manifold and injectors:

Installation of the fuel manifold together with injectors is performed in the reverse sequence. The following points should be noted when installing:

-

● Renew the O-rings at all opened connections. (when renewing the front O-ring, ensure that the plastic cap is not removed from the injector head. The O-ring must be pulled off over the plastic cap).

-

● Moisten the O-rings with clean engine oil.

-

● Insert injectors perpendicularly and in correct position into fuel manifold and secure with fasteners.

-

● Position fuel rail with secured injectors on intake manifold and press evenly into place.

-

● Renew hose clamps and ensure that they are securely fitted.

|