|

If a fault is displayed relating to "Databus... " or "...CAN bus":

-

‒ Check whether this is the correct engine control unit for this vehicle and if further CAN control unit are installed (part no. and coding).

If the correct control units are installed:

-

‒ Check that multiple connectors for control units are properly seated.

If the multiple connectors are too tight:

-

‒ Check the CAN bus system.

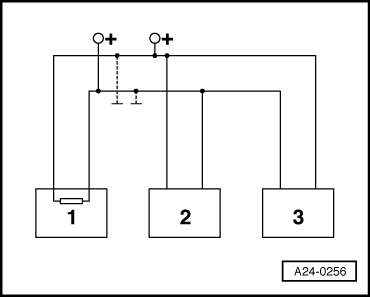

Checking a "two-line bus system"

The communication between three or more control units is carried out over a "two-line bus system".

-

‒ Evaluate the faults stored in the control units.

Note:

This helps to localise line faults.

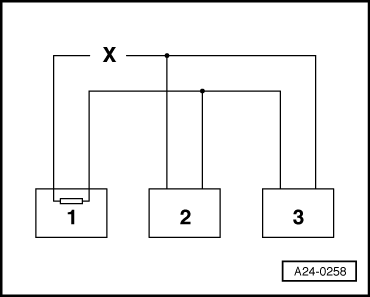

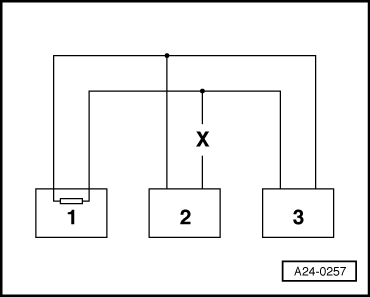

Example 1:

With the faults stored in the fault memories it can be seen that the control unit 1 does not communicate with control units 2 and 3.

|