A4 Mk1

|

Checking lambda control

Checking lambda probe and lambda control upstream of catalytic converter

|

| → When indicated on display: |

|

||

Note: During basic setting, the solenoid valve for the active carbon canister (valve -N80) is closed and the air conditioner compressor is switched off. |

| → When indicated on display: |

|

||

|

| → When adjacent display appears: |

|

||

|

| → When adjacent display appears: |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

Interpreting display group 033

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| → When indicated on display: |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Interpreting display group 032

Interpreting display group 032

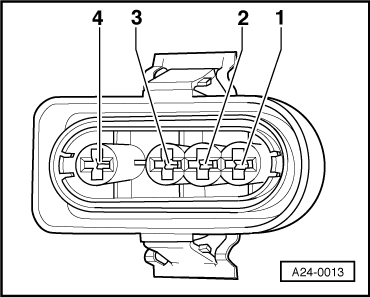

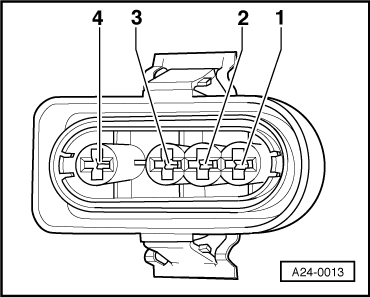

Checking basic voltage Fitting location of connectors => Installation position overview Page 24-5 Test requirements:

=> Current Flow Diagrams, Electrical Fault-Finding and Fitting Locations

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

If specified value is not attained:

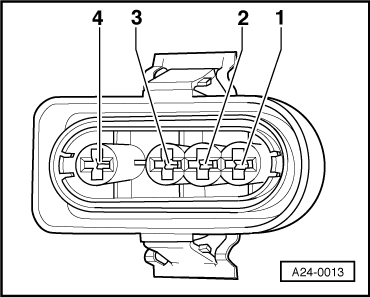

Check lambda probe wiring Bank 1 lambda probe 1 upstream of catalytic converter -G39 Fitting location of connectors => Installation position overview Page 24-5

|

|

||||||||||

|

|

|||||||

If no wiring fault is detected:

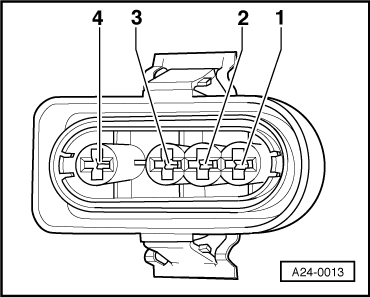

Checking lambda probe wiring bank 2 lambda probe 1 upstream of catalytic converter -G108 Fitting location of connectors => Installation position overview Page 24-5

|

|

||||||||||||||||

If no wiring fault is detected:

|