A4 Mk1

|

Servicing Motronic injection system

Checking fuel pressure regulator and holding pressure

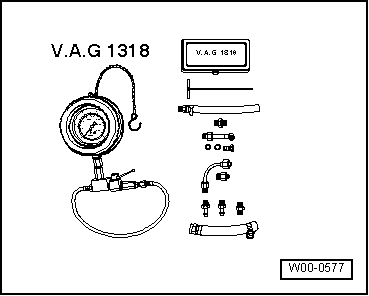

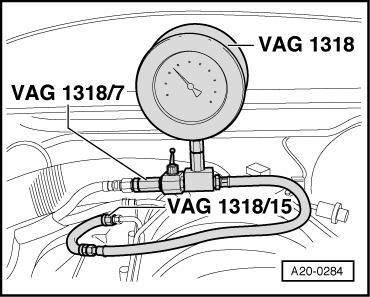

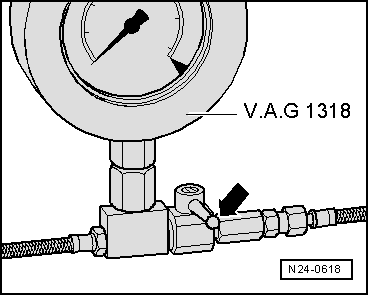

Special tools, testers and workshop equipment required |

|

|

Note: Fuel pressure regulator regulates fuel pressure as a function of intake pressure. As a result, the pressure drop at the injectors remains constant for each engine speed and load range. Test requirements:

=> Fuel Supply - Petrol Engines; Repair Group 20; Fuel Supply - FWD/Fuel supply - 4WD

Warning!

The fuel system is pressurised! Before loosening hose connections or opening the test connection (to measure fuel pressure), place a cloth around the connection. Then release pressure by carefully loosening the connection. Check system pressure |

|

|

Note: Replace pressure regulator if fuel emerges at the vacuum connection of the pressure regulator in the course of the following pressure test.

Note: When performing the following test, do not leave the engine running for an unnecessarily long time with the vacuum hose detached, because the higher fuel pressure causes the fuel/air mixture to be enriched. This could lead to the Lambda control limits to be exceeded, which would then result in a fault being recorded.

Checking holding pressure:

Note: The increase in temperature with the engine at operating temperature is caused by the expansion of the fuel and is normal.

|

|

|

If the pressure does not drop, the following faults are possible:

=> Fuel Supply - Petrol Engines; Repair Group 20; Fuel Supply - FWD/Fuel supply- 4WD Note: After the isolating valve has been closed, the pressure gauge shows the pressure after the isolating valve "induction manifold end" (direction of injectors, fuel pressure regulator). If the pressure before the isolating valve (tank direction) should now fall, the equipment cannot recognise this fact. For this reason, "If the pressure does not drop..." appears in the middle of this Page. If the pressure drops again, the following faults are possible:

Note: To disconnect the pressure gauge, close the cut-off valve, unscrew the union on adapter V.A.G 1318/15, then open the cut-off valve to drain off excess fuel into a suitable container. |