A4 Mk1

|

|

|

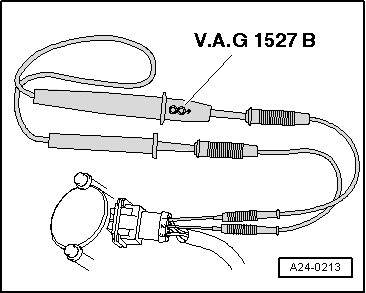

Testing activation of Hall sender Use test leads from adapter set V.A.G 1594 when carrying out the following tests. Fitting location of Hall sender -G40 .

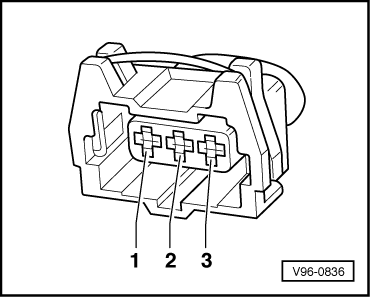

Note: The connector contacts are numbered on the back of the connector.

The diode test lamp should flash briefly once every two engine revolutions. Note: Diode test lamps with a low current draw continue to glow faintly between impulses from the engine control unit (rather than going out completely) and become much brighter when receiving an impulse. If the diode test lamp does not flash, test the voltage supply. Test voltage supply for Hall sender:

|

|

|

Testing signal wire for Hall sender:

Testing earth connection for Hall sender: |

|

|

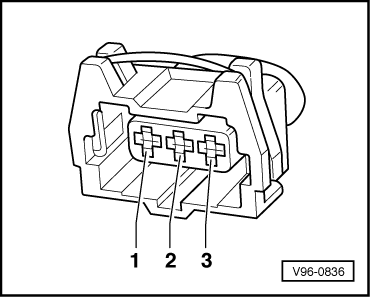

If all the readouts match the specifications but the diode test lamp does not flash (measurement taken between socket 1 and 2 without unplugging connector and while operating starter):

If the readouts do not match the specification, test the wiring. Testing wiring between Hall sender and engine control unit

|

|

|||||||||

=> Current flow diagrams, Electrical fault finding and Fitting locations binder

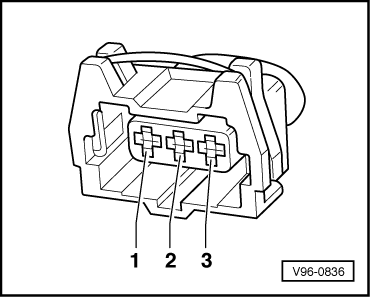

Testing phase position of Hall sender

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||

|

| → Indicated on display: |

|

||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||