A4 Mk1

|

Testing ignition system

Testing ignition coils

|

|

|

|

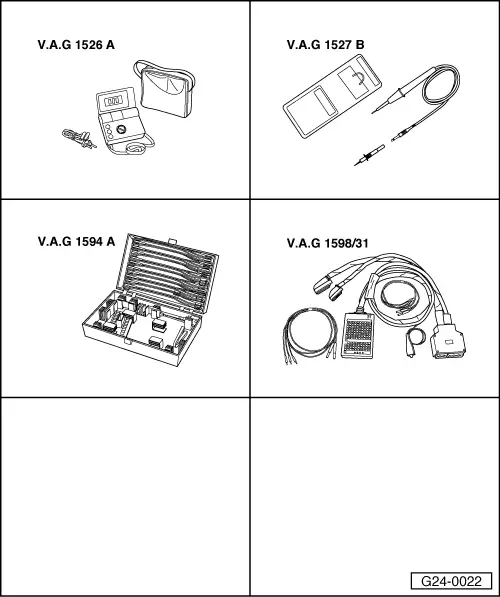

Special tools and workshop equipment required

|

|

|

|

Test sequence The procedure for identifying an inoperative or misfiring cylinder is as follows:

When the defective cylinder has been identified:

If the specification is not obtained:

If the specification is obtained:

If the fault moves with the spark plug:

If the fault remains in the same cylinder:

If the fault moves with the ignition coil:

If the fault remains in the same cylinder: |

|

|

|

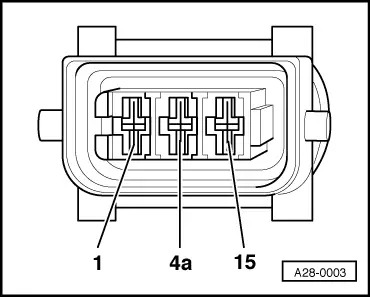

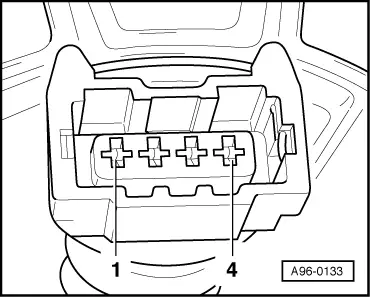

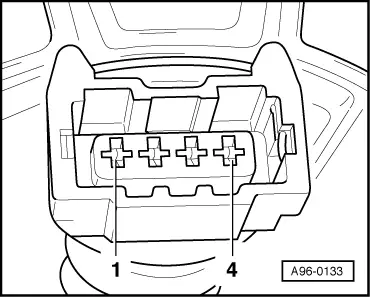

Test earth connection for ignition coil:

If the earth connection is OK: Test voltage supply to ignition coil: Note: It is important to ensure that no fuel is injected during the test as this would damage the catalytic converter. The connectors on the injectors must therefore be unplugged. Test requirement:

|

|

||||

If the specification is not obtained: Vehicles up to model year 1999:

=> Current flow diagrams, Electrical fault finding and Fitting locations binder |

|

|

|

Vehicles from model year 2000 onwards:

|

|

|

|

|

|

|

|

|

|

|

||||||||||

|

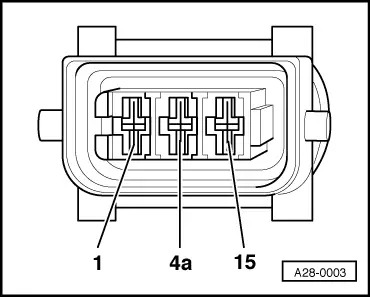

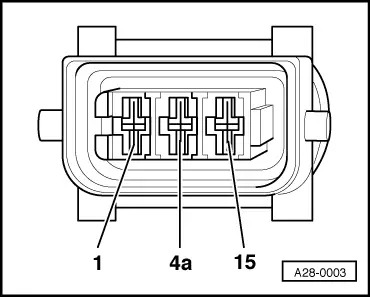

All models If the specification is obtained: Test activation:

If the test result at one contact is not as specified:

|

|

|

|

|

||||||||||||

|