A4 Mk1

| → Display: |

|

||

Note: During basic setting, the solenoid valve for the active carbon canister (valve N80) is closed and the air conditioner compressor is switched off by the engine control unit. |

| → Display: |

|

||

|

| → Display: |

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

If specified value is attained:

Interpreting display group 2

Interpreting display group 2

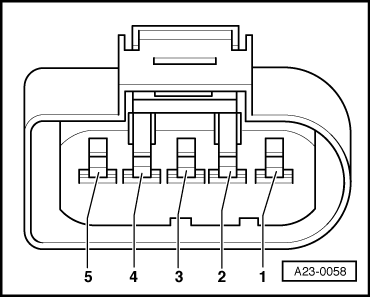

Testing voltage supply to air mass meter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

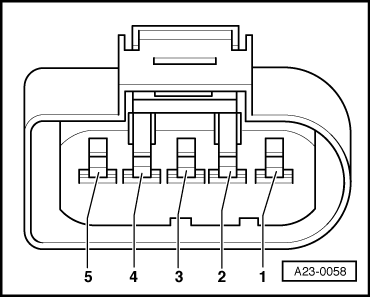

Note: Voltage supply to airflow meter is from fuel pump relay. If battery voltage is not present:

=> Current Flow Diagrams, Electrical Fault-Finding and Fitting Locations |

|

|

Note: Engine control unit earth is present at contact 3 of the connector. If specified value is not attained, check wiring => Page 24-69. |

|

|

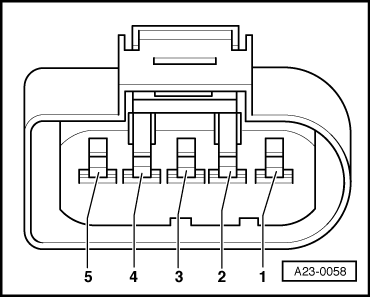

If specified value is not attained, check wiring => Page 24-69. Check wiring to airflow meter. Note: The signal wire is also checked during the wiring check.

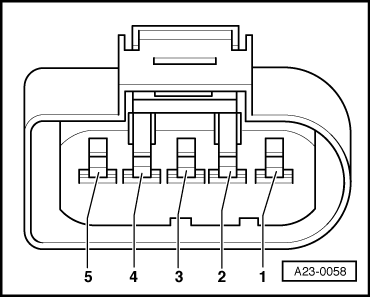

The following wiring connections are to be checked for open circuits and/or short to positive or negative. |

|

|||||||||

|