A4 Mk1

|

Checking ignition system

Checking engine speed sender -G28

|

|

|

|

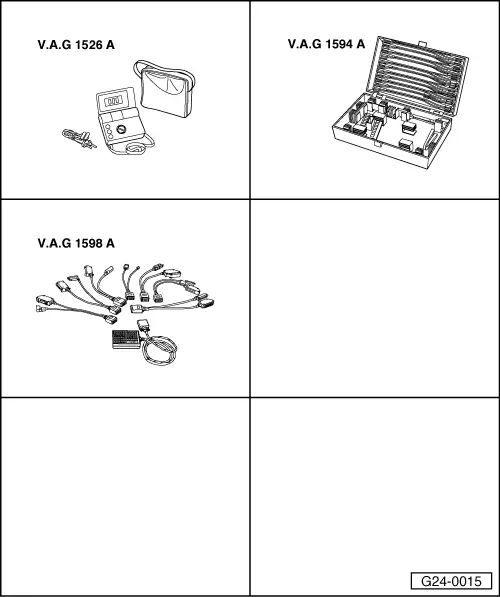

Special tools and workshop equipment required

Installation position => Installation position overview - Page 24-5

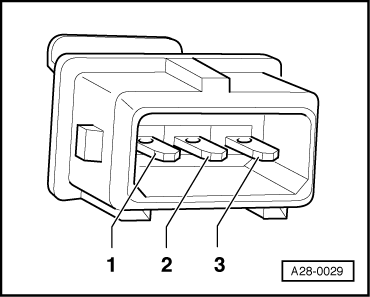

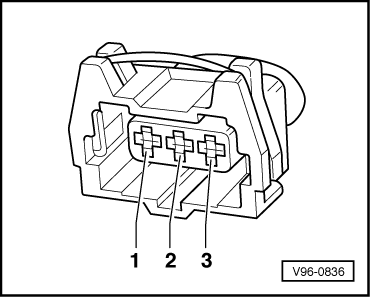

Checking internal resistance

|

|

|

If the specification is not obtained:

If specified values are not obtained:

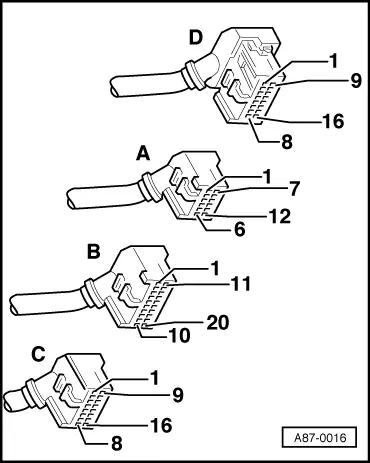

Checking wiring |

|

|

|

|

||||||||

=> "Current Flow Diagrams, Electrical Fault Finding and Fitting Locations" binder If no wiring fault is detected:

=> Electrical system; Repair group 27; Removing and installing starter

If no fault is found:

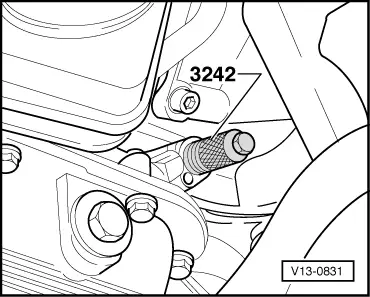

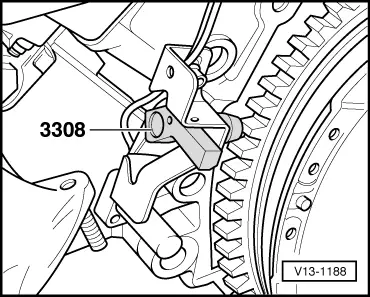

Adjusting holder for engine speed sender Notes:

|

|

|

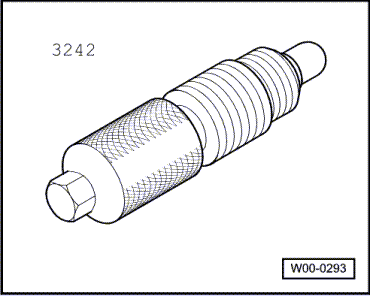

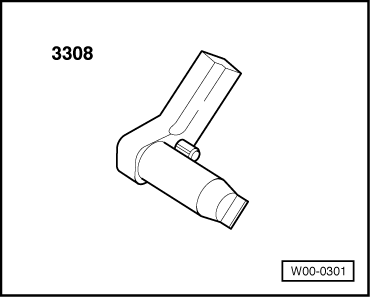

Special tools and workshop equipment required

|

|

|

Work sequence |

|

|

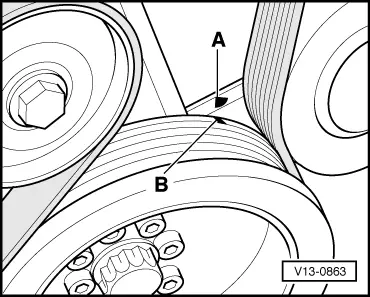

Note: TDC hole is located exactly behind the sender in the crankshaft (can be felt). Attention:

To avoid possible injury, never turn crankshaft whilst feeling for TDC. |

|

|

|

|

|

The remaining installation steps are carried out in the reverse sequence: |