-

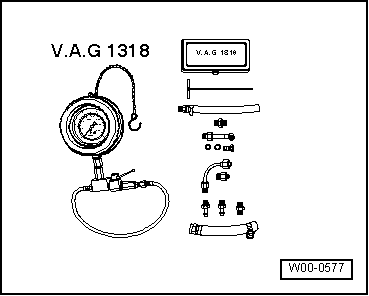

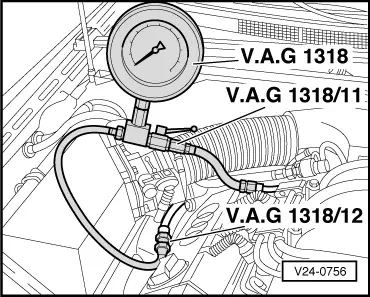

‒ → Connect up pressure gauge V.A.G 1318 with test adapters 1318/11 and 1318/12 between fuel feed pipe and fuel manifold; lever on pressure gauge set to - open position (lever in direction of flow).

-

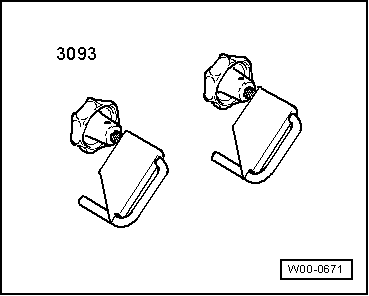

‒ Disconnect vacuum pipe between pressure regulator and intake manifold at the pressure regulator and seal off pipe with hose clamp 3093.

Notes:

-

◆ Renew pressure regulator if fuel emerges at the vacuum connection of the pressure regulator in the course of the following test procedure.

-

◆ When performing the following test, do not leave the engine running for an unnecessarily long time with the vacuum hose detached, because the higher fuel pressure causes the fuel/air mixture to be enriched. This could lead to the lambda control limits to be exceeded, which would then result in a fault being recorded.

-

‒ Start the engine and run at idling speed.

-

‒ Switch off air conditioner.

-

‒ Measure the fuel pressure.

-

‒ Specification: 3,8 ... 4.2 bar

-

‒ If the specified value is not attained, try renewing the pressure regulator and repeating the pressure test.

-

‒ If the specified value is still not attained, check the fuel pump/feed pipe for damage (e.g. crushing) and renew if necessary.

-

‒ If the specified value is exceeded, check the return pipe for damage (e.g. crushing) and renew if necessary.

-

‒ Attach vacuum hose to pressure regulator and observe drop in pressure on pressure gauge.

-

‒ Fuel pressure must decrease by approx. 0.5 bar when vacuum hose is attached.

- Perform the following checks if there is no change in pressure as described above:

-

‒ Check vacuum hose for cracks and damage.

-

‒ Check vacuum hose at intake manifold for blockage; to do so, pull off hose at pressure regulator and blow into it.

-

‒ Renew the pressure regulator if no leakage is found and the vacuum connection is not blocked.

Cehcking holding pressure:

-

‒ Holding pressure 10 minutes after switching off engine (minimum pressure).

-

‒ Specified value for cold engine: approx. 2.2 bar

-

‒ Specified value for warm engine: approx. 3.0 bar

If the specification is not obtained:

Note:

The increase in pressure in a warm engine due to fuel expansion is normal.

-

‒ Start the engine and run at idling speed.

-

‒ Allow the pressure to build up, then switch off the ignition. At the same time close the cut off valve on the pressure gauge V.A.G 1318 (valve lever at right angles to direction of flow).

If the pressure does not drop, the following faults are possible:

-

◆ Union between pressure gauge and fuel supply pipe leaking

-

◆ Supply pipe leaking at fuel tank

-

◆ Return valve in fuel pump leaking

=> Fuel Supply - Petrol Engines; Repair Group 20; Fuel Supply - FWD/Fuel supply- 4WD

If the pressure drops again, the following faults are possible:

-

◆ Fuel pressure regulator defective

-

◆ Injectors leaking

-

◆ Unions on pressure gauge downstream of cut-off valve leaking

Note:

To disconnect the pressure gauge, close the shut-off valve, unscrew the union on adapter V.A.G 1318/2, then open the shut-off valve to drain off excess fuel into a suitable container.

|