-

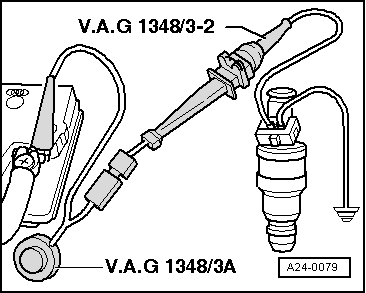

‒ → Connect one of the injector contacts to engine earth using test cable and crocodile clamp from V.A.G 1594.

-

‒ Connect second injector contact to positive using remote control V.A.G 1348/3 A, adapter cable V.A.G 1348/3-2 and auxiliary cable.

-

‒ Start final control diagnosis and select solenoid valve 1 for activated charcoal filter -N80 => Page 01-55. This activates the fuel pump, which will run for about 50 seconds.

-

‒ Check injectors for leaks (visual check). When the fuel pump is running, only 1 or 2 drops of fuel should escape from each injector during the 50-second running period.

-

‒ If the fuel loss is greater, switch off the fuel pump (terminate final control diagnosis) and renew the faulty injector.

-

‒ Start final control diagnosis again and select solenoid valve 1 for activated charcoal filter -N80.

Note:

The final control diagnosis cannot be re-started until the ignition has been switched off briefly.

-

‒ Immediately after selecting ACF solenoid valve (fuel pump will run for approx. 50 seconds), activate remote control V.A.G. 1348/3 A for 30 seconds.

Note:

When checking the injection quantity, also check the spray pattern. The spray pattern should be the same for all the injectors.

-

‒ Repeat test (i.e. start final control diagnosis) for all injectors.

-

‒ Once all four injectors have been actuated, place measuring glasses on a level surface.

Specification: 85...105 ml.

-

‒ If the measured value for one or more of the injectors is outside the tolerance range, switch off the fuel pump (terminate final control diagnosis) and renew the defective injector.

-

‒ If the measured values for all the injectors are outside the tolerance range, check the fuel pressure => Page 24-21.

Installation of the fuel manifold together with injectors is performed in the reverse sequence. The following points should be noted when installing:

-

● Renew the O-rings at all opened connections. (When renewing the front O-ring, make sure not to remove the plastic cap from the injector head. The O-ring must be pulled off over the plastic cap.)

-

● Moisten the O-rings with clean engine oil.

-

● Make sure that the injectors are installed in the correct positions.

-

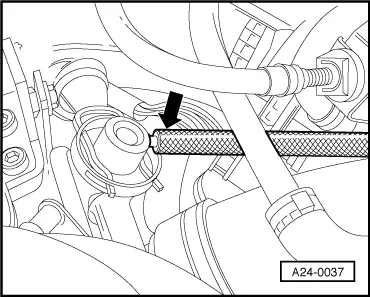

● Check to make sure that the retainer clamps are properly seated.

|