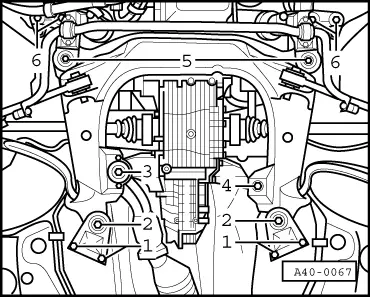

A4 Mk1

|

|

|

Removing

|

|

|

|

|

|

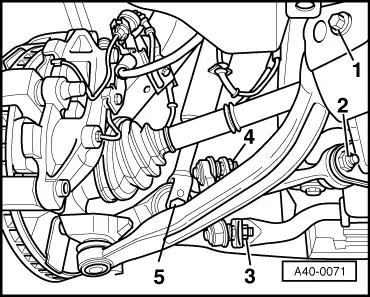

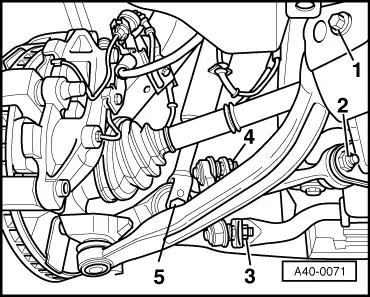

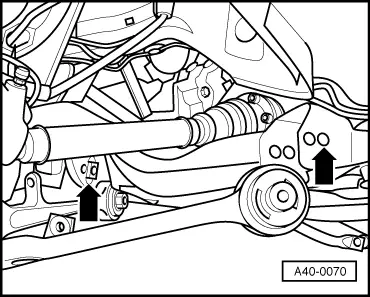

If this is not the case, wheel alignment must be performed after installing subframe. To avoid damaging joints of lower links provide support, e.g. using V.A.G 1383-A (engine and gearbox lifter), to guard against excessive rebound. |

|

|

|

|

|

Note: To excessive bending of pin-end joints of track control and guide links, they are to be attached to body with wire or the like.

|

|

|

For vehicles with headlight range control, refer to .

|

|

|

|

|

|

Installing Note: Always replace bolts and nuts. |

|

|

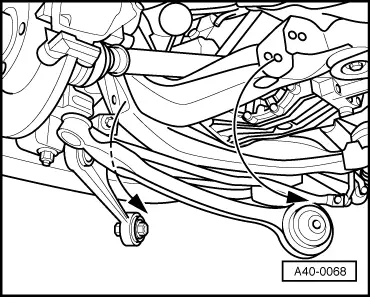

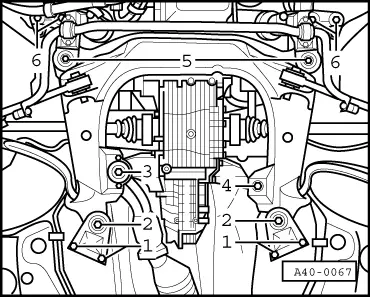

Note: Heed installation position of suspension strut/track control link bolted joint .

|

|

|

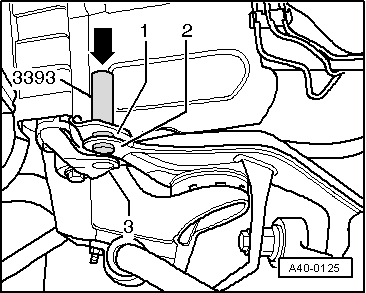

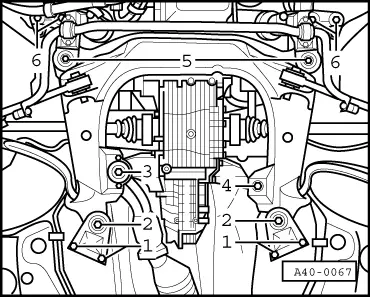

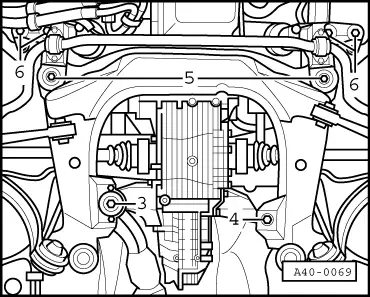

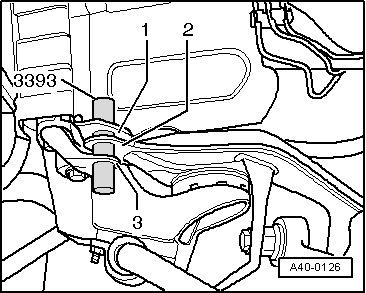

Before tightening, subframe must be located with respect to body using test bar 3393. |

|

|

Note: This locating procedureprovides a substitute for subsequent wheel alignment:

|

|

|

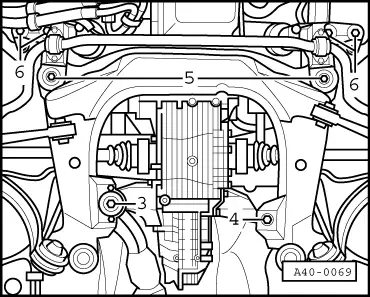

Tightening sequence/tightening torques Bonded rubber bushes can only be turned to a limited extent. The bolted joints at the suspension links are therefore not to be tightened until the vehicle is standing on the ground. |

|

|

Pay attention to modified connecting links and tightening torques

Notes:

|