A4 Mk1

|

|

|

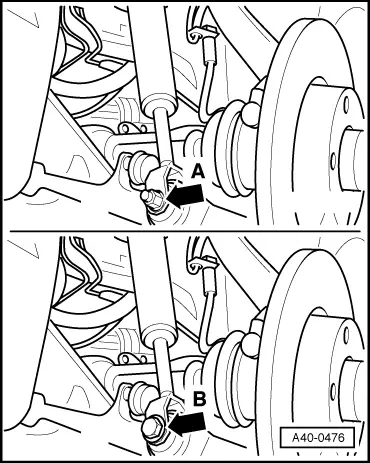

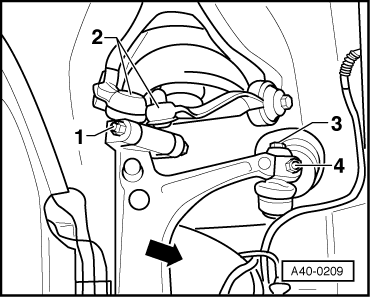

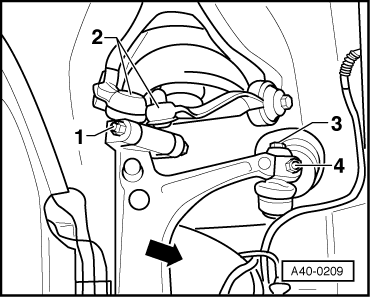

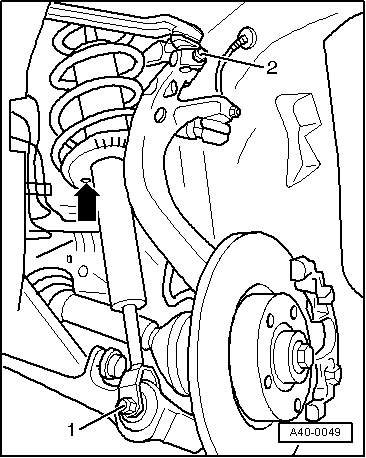

→ Note: The suspension strut bolted joint was re-positioned on vehicles as of the following chassis numbers, i.e. bolt head -arrow B- points in direction of travel and nut is located between track control link and guide link:

|

|

|

|

Removing

|

|

|

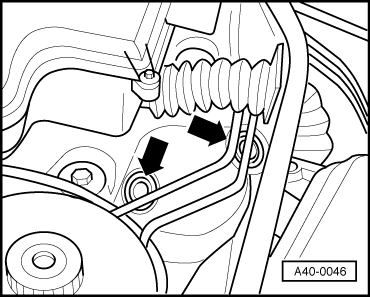

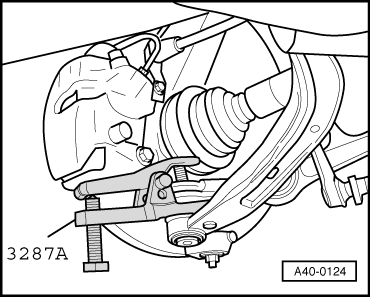

For vehicles with headlight range control, refer to . To avoid damaging joints of lower links provide support, e.g. using V.A.G 1383-A (engine and gearbox lifter), to guard against excessive rebound. |

|

|

|

|

|

If hexagon bolt cannot be removed from wheel bearing housing, bolt and links must be pressed out of wheel bearing housing. Slots in wheel bearing housing are never to be widened using a chisel or the like.

|

|

|

|

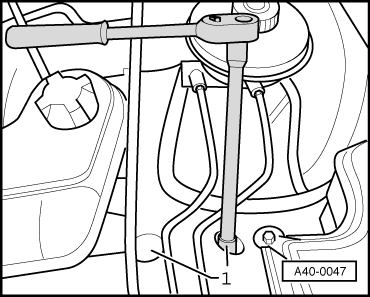

→ Bolts -3- and -4- are never to be slackened off. Otherwise wheel alignment must be checked. Guide link must be detached from wheel bearing housing to enable suspension strut/track control link hexagon bolt to be screwed out.

|

|

|

|

|

|

Notes:

|

|

|

|

Installing

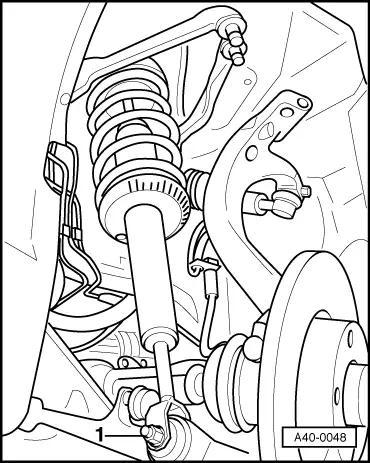

Note: Heed installation position of suspension strut/track control link bolted joint .

Bonded rubber bushes can only be turned to a limited extent. Suspension strut/track control link bolted joint is therefore only to be tightened when vehicle is standing on ground.

|