|

→ Socket designations of test box V.A.G 1598/20 are identical with contact designations on control unit -J104 as well as those on wiring harness connector.

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder

-

‒ Connect test box V.A.G 1598/20 to multi-pin connector on wiring harness.

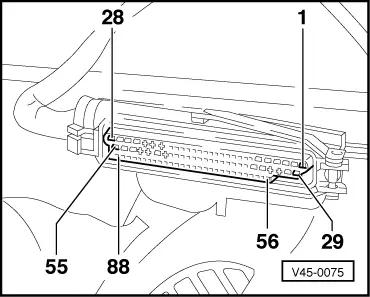

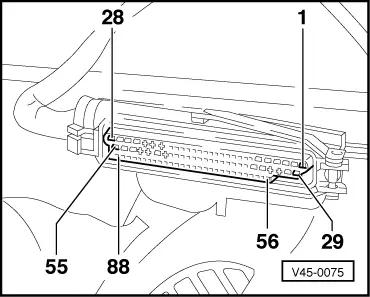

Contact assignment of control unit -J104

|

Multi-pin connector on control unit -J104

|

|

|

Contact

|

closed

|

|

Contact

|

|

1

|

=>

|

Voltage supply from terminal 15

TCS/ESP switch

|

-

5

|

|

2

|

=>

|

Voltage supply from terminal 15

Return pump relay -J105

Solenoid valve relay ABS -J106

Steering angle sender -G85; [control unit 8D0 907 389/A/D/E]

Steering angle sender -G85; [control unit 4B0 907 389]

|

86

86

5

3

|

|

3

|

=>

|

Hydraulic unit; actuation of outlet valve, front left -N102

|

15

|

|

4

|

=>

|

Hydraulic unit; actuation of outlet valve, rear right -N135

|

12

|

|

5

|

=>

|

Hydraulic unit; actuation of inlet valve, front left -N101

|

8

|

|

6

|

=>

|

Hydraulic unit; actuation of inlet valve, rear right -N133

|

2

|

|

7

|

=>

|

Return pump relay -J105 (earth)

|

85

|

|

8

|

=>

|

Front left speed sensor -G47

- Vehicles with 4WD

|

-

|

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder

|

Multi-pin connector on control unit -J104

|

|

|

Contact

|

closed

|

|

Contact

|

|

9

|

=>

|

Front left speed sensor -G47

- Vehicles with FWD

|

-

|

|

10

|

=>

|

Front left speed sensor -G47 (earth)

|

-

|

|

11

|

=>

|

Rear right speed sensor -G44

|

-

|

|

12

|

=>

|

Rear right speed sensor -G44 (earth)

|

-

|

|

13

|

=>

|

Rear left speed sensor -G46

|

|

|

14

|

=>

|

Rear left speed sensor -G46 (earth)

|

-

|

|

15

|

=>

|

Front right speed sensor -G45

|

-

|

|

16

|

=>

|

Front right speed sensor -G45 (earth)

|

-

|

|

17

|

=>

|

Not used

|

-

|

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder

|

Multi-pin connector on control unit -J104

|

|

|

Contact

|

closed

|

|

Contact

|

|

18

|

=>

|

Lateral acceleration sender -G200; signal wire [control unit 4B0 907 389]

|

2

|

|

18

|

=>

|

Lateral acceleration sender -G200; signal wire (combined sender for yaw rate and lateral acceleration) [control unit 8D0 907 389/A/D/E]

|

4

|

|

19

|

=>

|

Lateral acceleration sender -G200; (earth) [control unit 4B0 907 389]

|

1

|

|

19

|

=>

|

Not used; [control unit 8D0 907 389/A/D/E]

|

-

|

|

20

|

=>

|

Return pump relay -J105

Hydraulic unit; monitoring connection for return pump -V39

|

87

14

|

|

21

|

=>

|

Not used

|

-

|

|

22

|

=>

|

ESP hydraulic pump -V156; voltage supply

|

2

|

|

23

|

=>

|

Not used

|

-

|

|

24

|

=>

|

ESP hydraulic pump -V156; (earth)

|

1

|

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder

|

Multi-pin connector on control unit -J104

|

|

|

Contact

|

closed

|

|

Contact

|

|

25

|

=>

|

Hydraulic unit; actuation of outlet valve, rear left -N136

|

11

|

|

26

|

=>

|

Hydraulic unit; actuation of inlet valve, front right-N99

|

5

|

|

27

|

=>

|

Not used

|

-

|

|

28

|

=>

|

Earth connection, terminal 31

|

-

|

|

29

|

=>

|

Earth connection, terminal 31

|

-

|

|

30

|

=>

|

Not used

|

-

|

|

31

|

=>

|

Dash panel insert; TCS/ESP-lamp -K86 [control unit 4B0 907 389]

|

=> CFD

|

|

31

|

=>

|

Wheel speed sensor output rear left; [control unit 8D0 907 389/A/D/E]

|

-

|

|

32

|

=>

|

Dash panel insert, ABS/EDL lamp -K47

|

=> CFD

|

|

33

|

=>

|

Not used

|

-

|

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder

|

Multi-pin connector on control unit -J104

|

|

|

Contact

|

closed

|

|

Contact

|

|

34

|

=>

|

Yaw rate sender -G202; voltage supply; [control unit 4B0 907 389]

|

2

|

|

34

|

=>

|

Yaw rate sender -G202; voltage supply (combined sender for yaw rate and lateral acceleration) [control unit 8D0 907 389/A/D/E]

|

1

|

|

35

|

=>

|

Not used

|

-

|

|

36

|

=>

|

Not used; [control unit 4B0 907 389]

|

-

|

|

36

|

=>

|

Solenoid valve relay -J106 (earth); [control unit 8D0 907 389/A/D/E]

|

85

|

|

37

|

=>

|

Solenoid valve relay -J106 (earth); [control unit 4B0 907 389]

|

85

|

|

37

|

=>

|

Not used; [control unit 8D0 907 389/A/D/E]

|

-

|

|

38

|

=>

|

Not used

|

-

|

|

39

|

=>

|

Not used

|

-

|

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder

|

Multi-pin connector on control unit -J104

|

|

|

Contact

|

closed

|

|

Contact

|

|

40

|

=>

|

Not used

|

-

|

|

41

|

=>

|

Not used

|

-

|

|

42

|

=>

|

Brake light switch -F; brake test switch

|

4

|

|

43

|

=>

|

Not used

|

-

|

|

44

|

=>

|

TCS/ESP switch

|

6

|

|

45

|

=>

|

Not used

|

-

|

|

46

|

=>

|

Diagnostic connector; K-wire

|

7

|

|

47

|

=>

|

Not used

|

-

|

|

48

|

=>

|

Brake light switch -F; brake light switch

|

2

|

|

49

|

=>

|

Hydraulic unit -N55; actuation of switch valve 1 for ESP -N225

|

7

|

|

50

|

=>

|

Hydraulic unit -N55; actuation of ESP -N226

|

6

|

|

51

|

=>

|

Voltage supply, terminal 30 for ESP hydraulic pump -V156;

|

-

|

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder

|

Multi-pin connector on control unit -J104

|

|

|

Contact

|

closed

|

|

Contact

|

|

52

|

=>

|

Hydraulic unit -N55; actuation of ESP high-pressure valve 2 -N228

|

4

|

|

53

|

=>

|

Hydraulic unit -N55; actuation of ABS inlet valve rear left -N134

|

3

|

|

54

|

=>

|

Hydraulic unit -N55; actuation of ESP high-pressure valve 1 -N227

|

1

|

|

55

|

=>

|

Hydraulic unit -N55; actuation of outlet valve front right -N100

|

9

|

|

56

|

=>

|

Not available

|

-

|

|

57

|

=>

|

Not available

|

-

|

|

58

|

=>

|

Not available

|

-

|

|

59

|

=>

|

Not available

|

-

|

|

60

|

=>

|

Not available

|

-

|

|

61

|

=>

|

Not used

|

-

|

|

62

|

=>

|

Not used

|

-

|

|

63

|

=>

|

Not used

|

-

|

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder

|

Multi-pin connector on control unit -J104

|

|

|

Contact

|

closed

|

|

Contact

|

|

64

|

=>

|

CAN bus low; Engine control unit, Gearbox control unit,

Steering angle sender-G85

|

=> CFD

2

|

|

65

|

=>

|

Not used; [control unit 4B0 907 389]

|

-

|

|

65

|

=>

|

CAN bus screen; [control unit 8D0 907 389/A/D/E]

|

-

|

|

66

|

=>

|

CAN bus high (engine control unit, gearbox control unit,

Steering angle sender -G85)

|

=> CFD

3

|

|

67

|

=>

|

Brake pressure sender -G201; (earth) [control unit 4B0 907 389]

|

1

|

|

67

|

=>

|

Brake pressure sender -G201; voltage supply [control unit 4B0 907 389/A/D/E]

|

1

|

|

68

|

=>

|

Brake pressure sender -G201; signal wire

|

2

|

|

69

|

=>

|

Brake pressure sender -G201; voltage supply [control unit 4B0 907 389]

|

3

|

|

69

|

=>

|

Brake pressure sender -G201; (earth) [control unit 8D0 907 389/A/D/E]

|

3

|

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder

|

Multi-pin connector on control unit -J104

|

|

|

Contact

|

closed

|

|

Contact

|

|

70

|

=>

|

Wheel speed sensor output rear left; [control unit 4B0 907 389]

|

=> CFD

|

|

70

|

=>

|

Dash panel insert; TCS/ESP-lamp -K86; [control unit 8D0 907 389/A/D/E]

|

=> CFD

|

|

71

|

=>

|

Speed sensor output, rear right.

|

=> CFD

|

|

72

|

=>

|

Not used; [control unit 4B0 907 389]

|

-

|

|

72

|

=>

|

Wheel speed sensor output front left; [control unit 8D0 907 389/A/D/E]

|

=> CFD

|

|

73

|

=>

|

Not used; [control unit 4B0 907 389]

|

-

|

|

73

|

=>

|

Wheel speed sensor output front right; [control unit 8D0 907 389/A/D/E]

|

=> CFD

|

|

74

|

=>

|

Not used

|

-

|

|

75

|

=>

|

Lateral acceleration sender -G200; voltage supply,

[control unit 4B0 907 389]

|

3

|

|

75

|

=>

|

Not used; [control unit 8D0 907 389/A/D/E]

|

-

|

|

76

|

=>

|

Handbrake warning switch -F9

|

=> CFD

|

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder

|

Multi-pin connector on control unit -J104

|

|

|

Contact

|

closed

|

|

Contact

|

|

77

|

=>

|

Yaw rate sender -G202; test signal [control unit 4B0 907 389]

|

5

|

|

77

|

=>

|

Yaw rate sender -G202; test signal (combined sender for yaw rate and lateral acceleration) [control unit 8D0 907 389/A/D/E]

|

3

|

|

78

|

=>

|

Yaw rate sender -G202; reference signal [control unit 4B0 907 389]

|

4

|

|

78

|

=>

|

Yaw rate sender -G202; reference signal (combined sender for yaw rate and lateral acceleration) [control unit 8D0 907 389/A/D/E]

|

5

|

|

79

|

=>

|

Yaw rate sender -G202; signal wire; [control unit 4B0 907 389]

|

3

|

|

79

|

=>

|

Yaw rate sender -G202; signal wire (combined sender for yaw rate and lateral acceleration) [control unit 8D0 907 389/A/D/E]

|

6

|

|

80

|

=>

|

Yaw rate sender -G202; (earth) [control unit 4B0 907 389]

|

1

|

|

80

|

=>

|

Yaw rate sender -G202; (earth) (combined sender for yaw rate and lateral acceleration) [control unit 8D0 907 389/A/D/E]

|

2

|

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder

|

Multi-pin connector on control unit -J104

|

|

|

Contact

|

closed

|

|

Contact

|

|

81

|

=>

|

Not used

|

-

|

|

82

|

=>

|

Not used

|

-

|

|

83

|

=>

|

Not used

|

-

|

|

84

|

=>

|

Not used

|

-

|

|

85

|

=>

|

Not used

|

-

|

|

86

|

=>

|

Not used; [control unit 4B0 907 389]

|

-

|

|

86

|

=>

|

Dash panel insert, standing time signal; [control unit 8D0 907 389/A/D/E]

|

=> CFD

|

|

87

|

=>

|

Not used

|

-

|

|

88

|

=>

|

Not used

|

-

|

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder

Notes on fault table

-

◆ The socket descriptions of test box V.A.G 1598 are identical to the contact descriptions of control unit -J104 in the current flow diagram. Incorrect test procedures can cause system damage. Do not make connections between any contacts other than those listed in the test table.

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder

-

◆ The specified values refer to the readings obtained on tester V.A.G 1526 and are not necessarily applicable to other test units.

-

◆ If the readings obtained do not match the specified values, carry out the fault remedy measures in the right-hand part of the table.

=> Current Flow Diagrams, Electrical Fault-finding and Fitting Locations binder

-

◆ If the specified values are achieved, also check wiring for loose contacts and short circuit to positive and earth. This applies especially to sporadic faults.

-

◆ Use test leads V.A.G 1594 for checking continuity (bridging leads).

-

◆ If the measured figures only differ slightly from the specified values, clean the sockets and plugs of the testers and test leads (with contact spray G 000 700 04) and repeat the check. Before replacing components, check wiring and connections again. This is particularly important if the specification calls for a resistance reading of less than 10 ω.

|