A4 Mk1

|

|

|

Note

Note |

|

|

|

Note

Note |

|

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note

Note

Note

|

|

Note

Note

|

|

| Component | Nm |

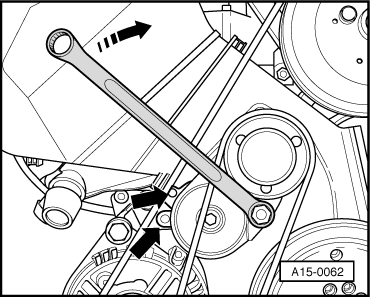

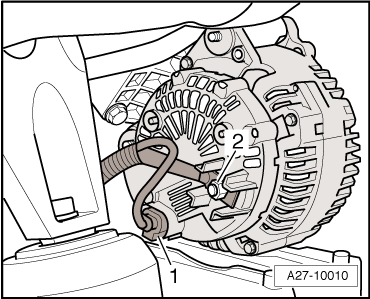

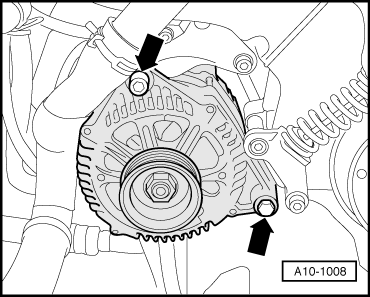

| Alternator to engine | 23 |

| 30/B+ terminal to alternator | 16 |

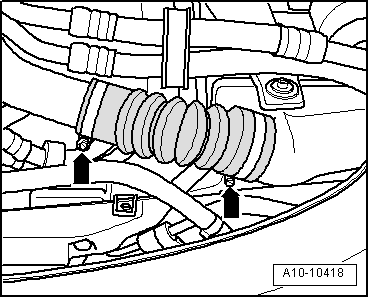

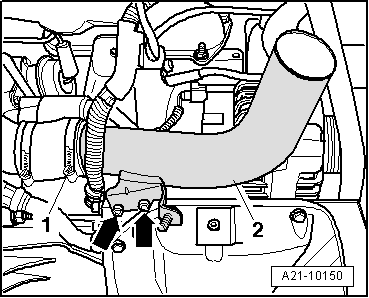

| Air intake pipe to sump (top section) | 10 |

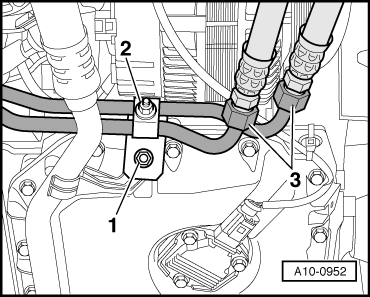

| Bracket for refrigerant line to sump (top section) | 9 |

| Clamp to bracket for refrigerant line | 9 |