A4 Mk2

|

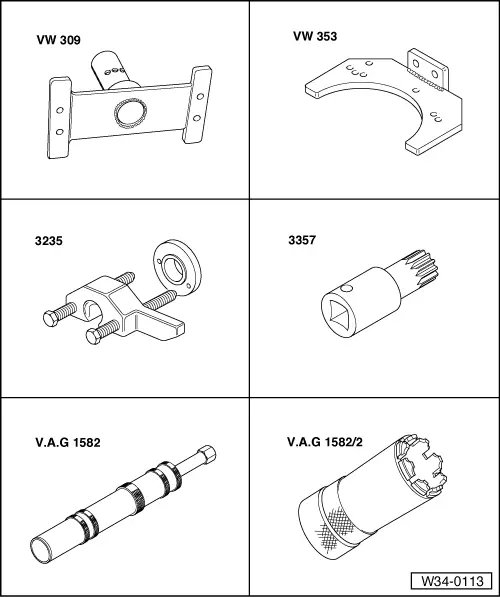

| Special tools and workshop equipment required |

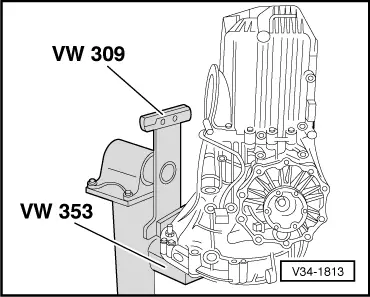

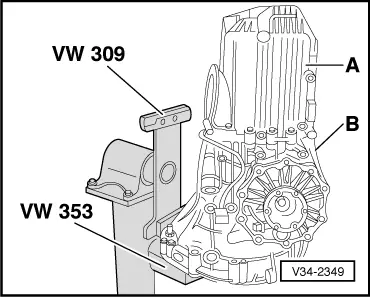

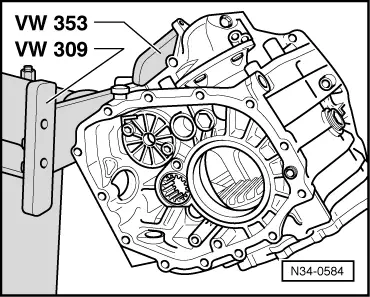

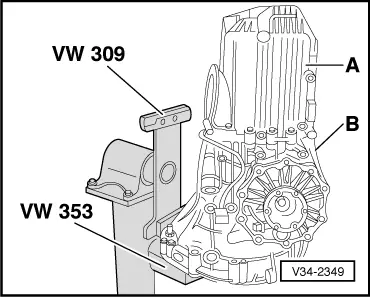

| t | Retaining plate -VW 309- |

| t | Gearbox support -VW 353- |

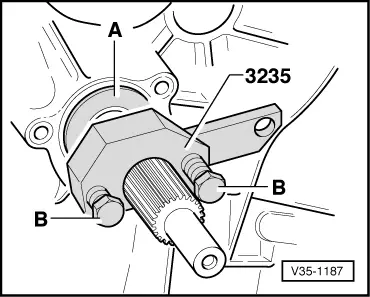

| t | Fitting tool -3235- or fitting tool -T10246- |

| t | Multi-point bit -3357- |

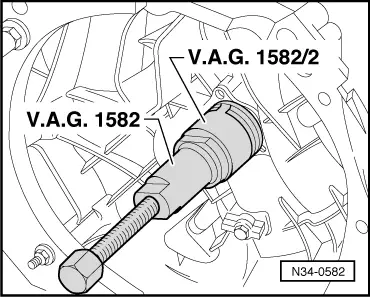

| t | Tapered roller bearing puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/2- |

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|