A4 Mk2

| Clutch release mechanism - exploded view |

| 1 - | Gearbox |

| 2 - | Ball head stud |

| q | 25 Nm |

| q | Lubricate with MoS2 grease |

| 3 - | Intermediate piece |

| 4 - | Dished spring |

| q | Smaller diameter (convex side) faces guide sleeve |

| 5 - | O-ring |

| q | Renew |

| 6 - | Input shaft oil seal |

| q | Available as replacement part together with guide sleeve → Item |

| q | Pack space between sealing lip and dust lip half-full with sealing grease -G 052 128 A1-. |

| 7 - | Guide sleeve |

| q | Available as replacement part together with oil seal → Item |

| q | Installation position: Oil drain hole points downwards |

| q | Before removing and installing, cover input shaft splines with a shrink-fit hose to protect oil seal → Item |

| 8 - | Retaining spring |

| q | Secure to clutch release lever |

| 9 - | Torx socket head bolt |

| q | 35 Nm |

| q | Self-locking |

| q | Always renew |

| 10 - | Clutch release lever |

| q | Before installing, lubricate area which makes contact with plunger of slave cylinder with copper grease, e.g. Z 381 351 TE |

| 11 - | Release bearing |

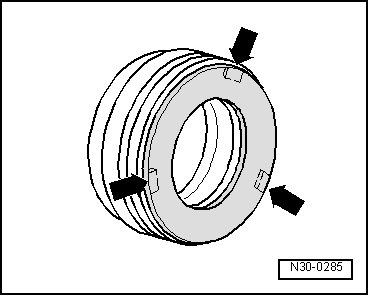

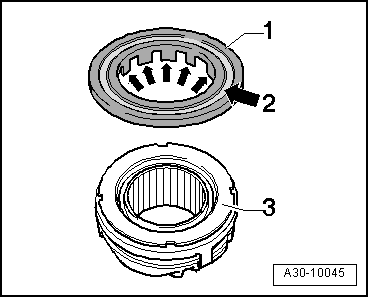

| q | With or without plastic ring, depending on version → Fig. |

| q | Checking and servicing release bearing with glued plastic ring → Fig. |

| q | Checking release bearing with mechanically attached plastic ring → Fig. |

| q | Renew if groove worn on plastic ring is too deep → Fig. |

| q | Do not wash out bearing; wipe clean only |

| q | Renew bearing if noisy |

| q | Retainer lugs on release bearing must engage in release lever |

| 12 - | Clutch slave cylinder |

| q | Do not operate clutch pedal after slave cylinder has been removed |

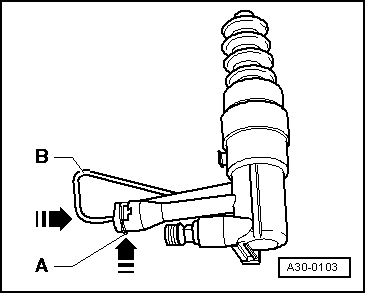

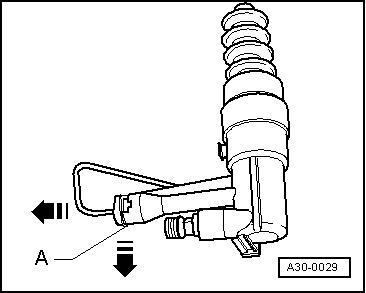

| q | Disconnecting pipe/hose assembly → Fig. |

| q | Connecting pipe/hose assembly → Fig. |

| q | Removing and installing → Chapter |

| q | Follow correct procedure when bleeding → Chapter |

| q | Tighten bleeder valve to 4.5 Nm |

| 13 - | Hexagon socket head bolt |

| q | 23 Nm |

| q | Clutch slave cylinder to gearbox |

| q | Self-locking |

| q | Always renew |

| 14 - | Bracket |

| q | For pipe/hose assembly |

| q | Attached to gearbox together with slave cylinder |

| 15 - | Plunger |

| q | Lubricate end of plunger with copper grease, e.g. Z 381 351 TE |

|

|

Note

Note

|

|

Note

Note

|

|