A4 Mk2

| Dismantling and assembling differential |

| Special tools and workshop equipment required |

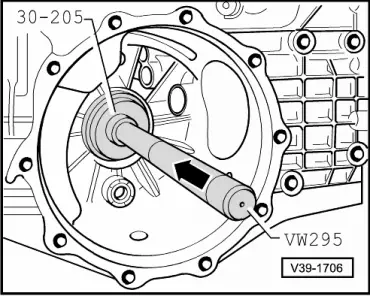

| t | Drift -VW 295- |

| t | Thrust plate -VW 401- |

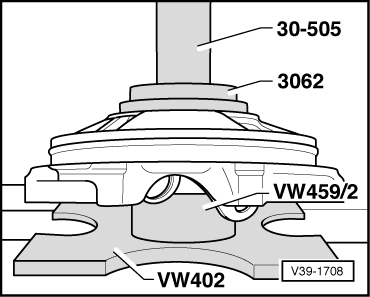

| t | Thrust plate -VW 402- |

| t | Press tool -VW 412- |

| t | Removal and installing tool -VW 459- |

| t | Thrust pieces for pinion shaft bearing -VW 470- |

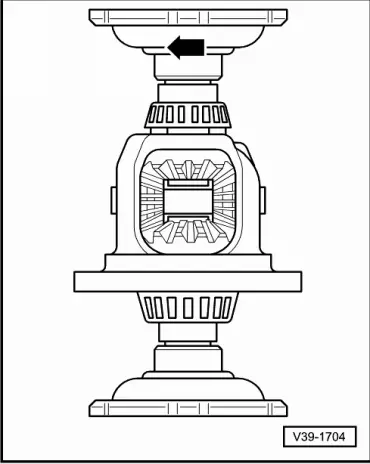

| t | Thrust plate -30-205- |

| t | Mandrel -30-505- |

| t | Press tool -40-21- |

| t | Thrust plate -40-105- |

| t | Thrust pad -3062- |

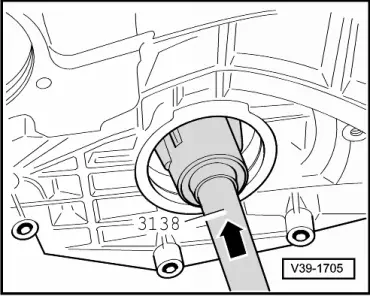

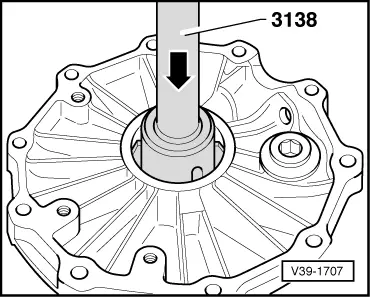

| t | Drift -3138- |

| t | Tapered roller bearing puller -V.A.G 1582- |

| t | Adapter -V.A.G 1582/3- |

| t | Adapter -V.A.G 1582/6- |

| Differential - exploded view of components |

Note

Note| Adjustment is required if gearbox housing, differential cage, cover for final drive, crown wheel or tapered roller bearings are being renewed → Anchor. |

| 1 - | Gearbox housing |

| 2 - | Shim “S2” |

| q | Note thickness |

| q | Table of adjustments → Anchor |

| 3 - | Small tapered roller bearing outer race |

| q | Driving out → Fig. |

| q | Driving in → Fig. |

| 4 - | Small tapered roller bearing inner race |

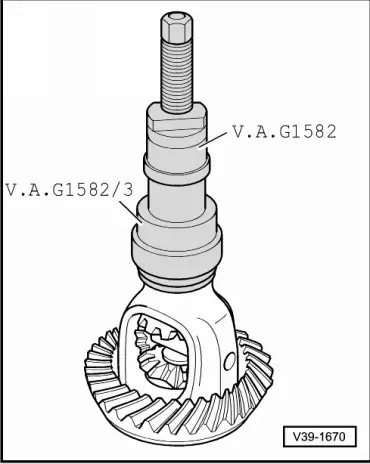

| q | Pulling off → Fig. |

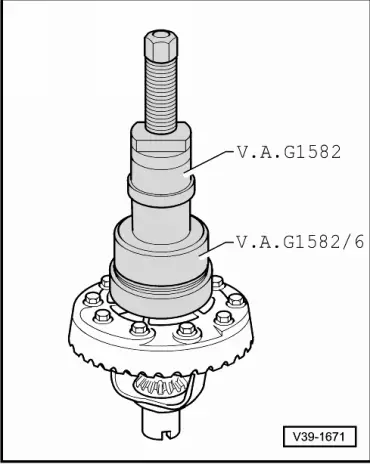

| q | Pressing on → Fig. |

| q | Low-friction bearing; do not oil bearing when measuring friction torque |

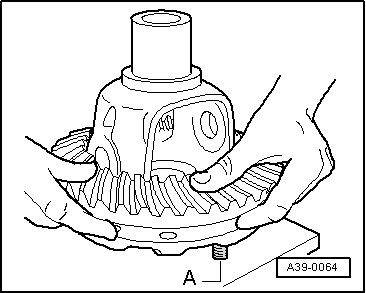

| 5 - | Crown wheel |

| q | Is mated with pinion shaft (final drive gear set), always renew together as a set |

| q | Select correct version according to code letters → Parts catalogue |

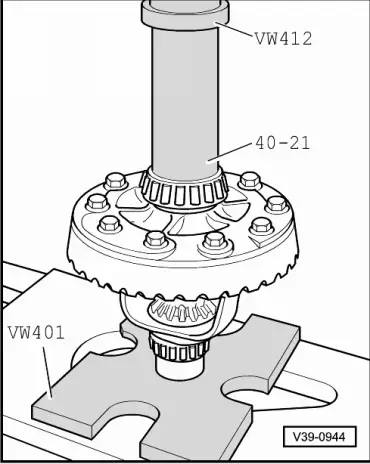

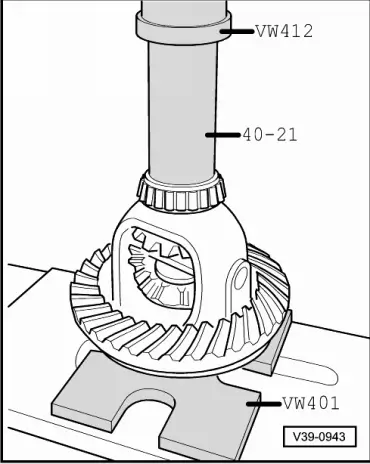

| q | Removing → Fig. |

| q | Installing → Fig. |

| 6 - | Differential cage |

| 7 - | Crown wheel bolt, 60 Nm + 45° further |

| q | Renew |

| q | Use only genuine bolts |

| 8 - | Large tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| q | Low-friction bearing; do not oil bearing when measuring friction torque |

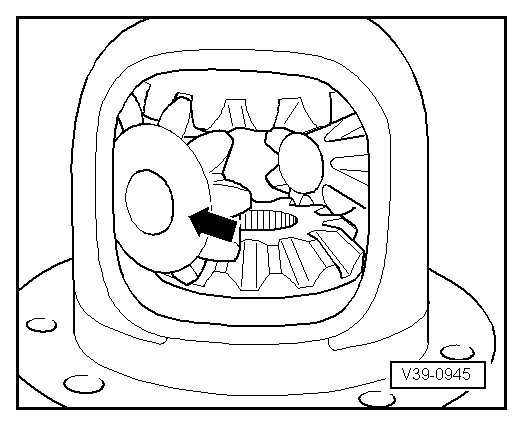

| 9 - | Drive wheel |

| q | For speedometer sender -G22- |

| q | Not fitted from 07.2002 |

| q | Removing and installing → Chapter |

| q | Fit the drive wheel carefully onto the differential, making sure that it is kept straight. Do not use force; the drive wheel can break easily |

| q | Installation position: shoulder -arrow- towards differential |

| 10 - | Large tapered roller bearing outer race |

| q | Driving out → Fig. |

| q | Driving in → Fig. |

| 11 - | Shim “S1” |

| q | Note thickness |

| q | Table of adjustments → Anchor |

| 12 - | Cover for final drive |

| q | With O-ring |

| q | Renew O-ring |

| q | Lubricate O-ring with oil before installing |

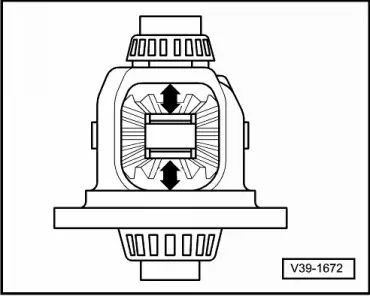

| 13 - | Shims |

| q | Re-determining thickness → Fig. |

| 14 - | Sun wheels |

| q | Installing → Fig. |

| q | Adjusting → Fig. |

| 15 - | Threaded piece |

| 16 - | Thrust washer |

| q | Check for cracks and chipping |

| 17 - | Planet pinions |

| q | Installing → Fig. |

| q | Adjusting → Fig. |

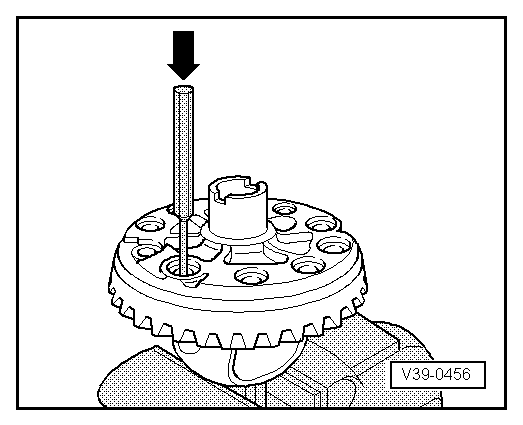

| 18 - | Differential pinion pin |

| q | Drive out with drift after removing spring pin |

| q | Align thrust washers before driving in |

| 19 - | Spring pin |

| q | Renew |

| q | Drive in flush |

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

Note

Note |

|

|

|

| Available shims - Thickness of shims in mm 1) | ||||

| 0.50 | 0.70 | 0.90 | ||

| 0.60 | 0.80 | 1.00 | ||

| ||||

|

|

|

|

|

|

|

|

WARNING

WARNING