A4 Mk2

|

| Special tools and workshop equipment required |

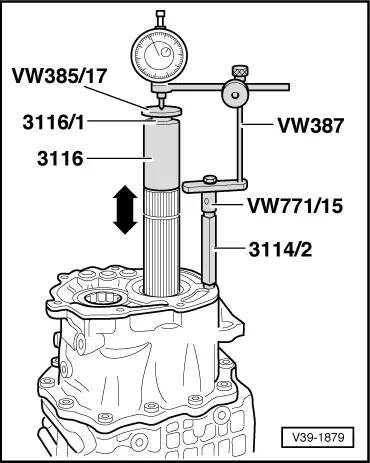

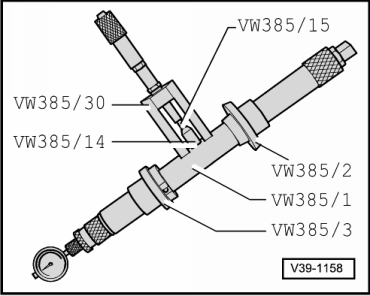

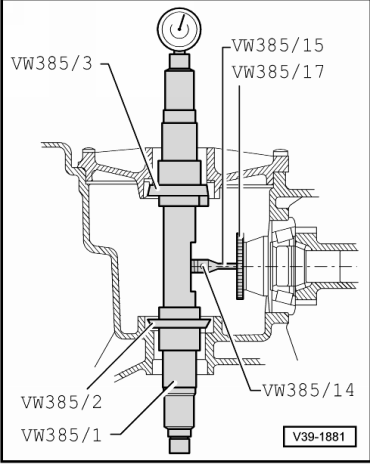

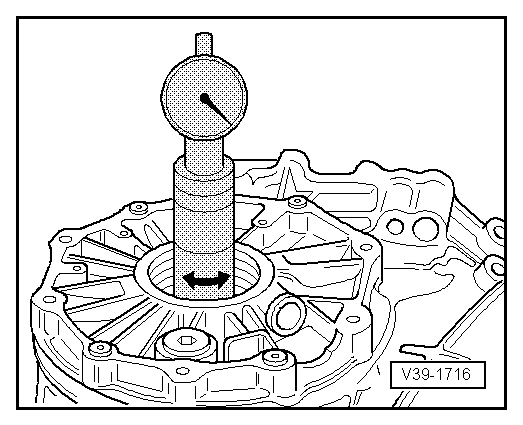

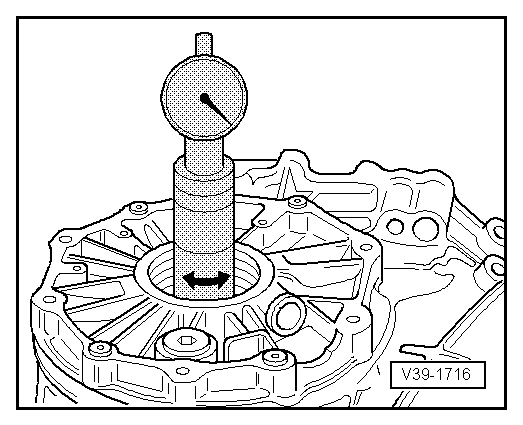

| t | Universal measuring tool -VW 385- |

| t | Universal dial gauge bracket -VW 387- |

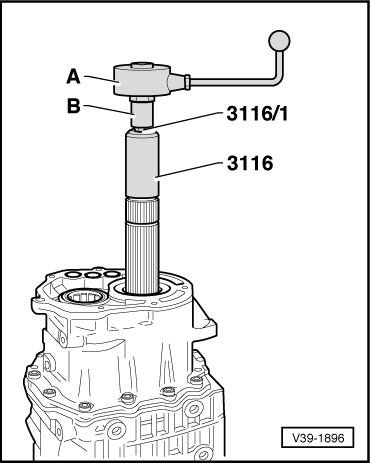

| t | Thrust plate -VW 402- |

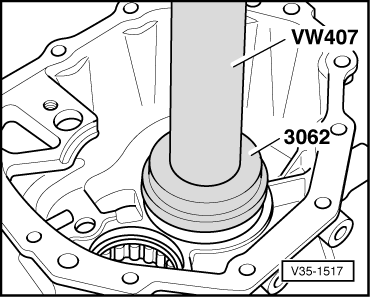

| t | Press tool -VW 407- |

| t | Multi-purpose tool -VW 771- |

| t | Thrust pad -3062- |

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

| Example: | |

| Inserted shim “S4*” | 1.00 mm |

| Dial gauge reading (example) | + 0.90 mm |

| Bearing preload (constant value) | + 0.15 mm |

| Total shim thickness “Stotal” for “S3” + “S4” | = 2.05 mm |

|

| Example: | |

| Total shim thickness “Stotal” for “S3” + “S4” | 2.05 mm |

| Inserted shim “S4*” | – 1.00 mm |

| Thickness of shim “S3*” | = 1.05 mm |

|

Note

Note

|

|

|

|

Note

Note

|

|

| Example: | |

| Inserted shim “S3*” | 1.05 mm |

| Allowance “r” marked on crown wheel | + 0.35 mm |

| Measured value “e” (in red scale) | – 0.16 mm |

| Thickness of shim “S3” | = 1.24 mm |

|

| Available shims - Thickness of shims in mm 1)2) | ||||||

| 0.45 | 0.60 | 0.75 | ||||

| 0.50 | 0.65 | 0.80 | ||||

| 0.55 | 0.70 | 0.85 | ||||

| ||||||

|

| Example: | |

| Total shim thickness “Stotal” for “S3” + “S4” | 2.05 mm |

| Thickness of shim “S3” | – 1.24 mm |

| Thickness of shim “S4” | = 0.81 mm |

|

| Available shims - Thickness of shims in mm 1)2) | ||||||

| 0.45 | 0.65 | 0.85 | ||||

| 0.50 | 0.70 | 1.25 | ||||

| 0.55 | 0.75 | |||||

| 0.60 | 0.80 | |||||

| ||||||

Note

Note

|

|

Note

Note

|

|

|

|