A4 Mk2

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

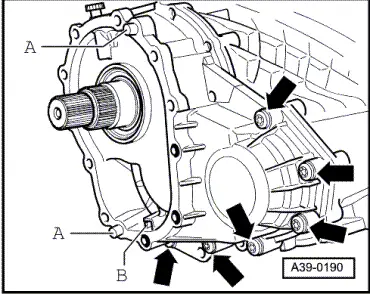

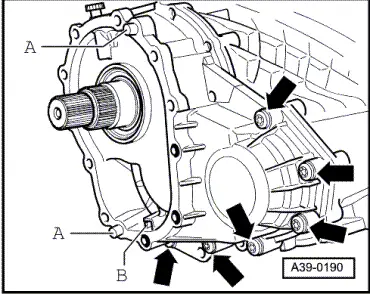

| Component | Nm |

| Intermediate flange for front axle drive to gearbox housing | 23 |

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

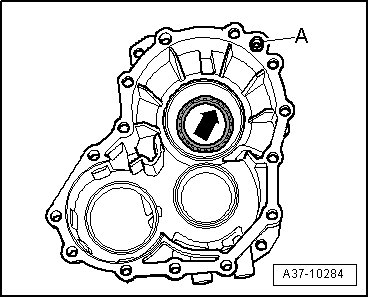

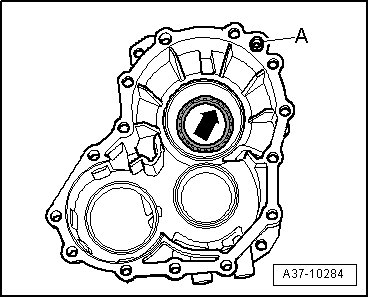

| Component | Nm |

| Intermediate flange for front axle drive to gearbox housing | 23 |