A4 Mk2

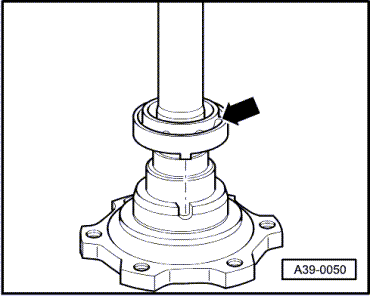

| Renewing oil seal and grooved ball bearing for flange shaft (left-side) |

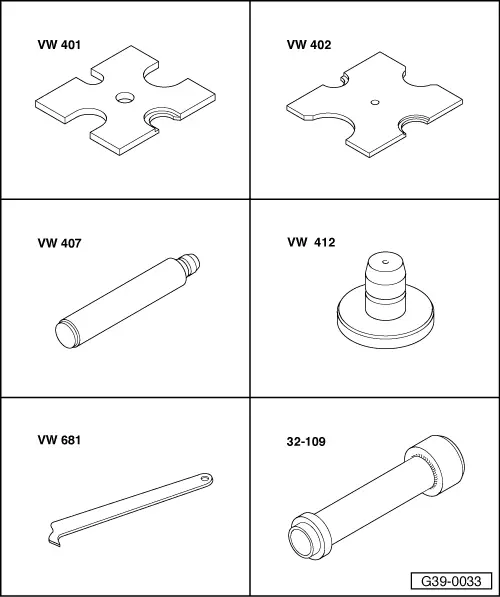

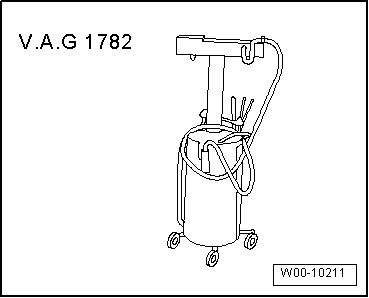

| Special tools and workshop equipment required |

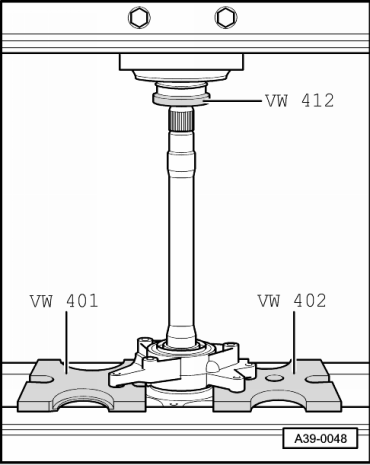

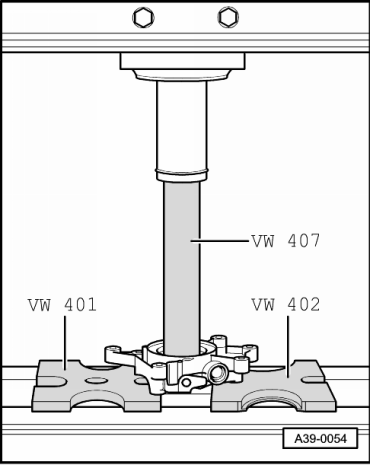

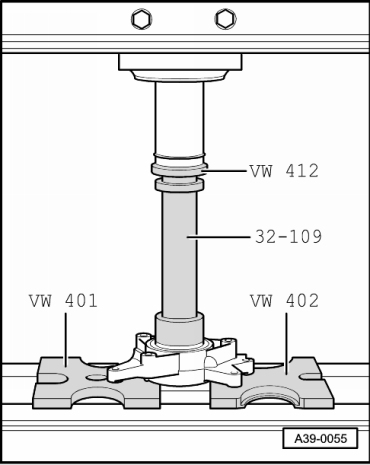

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

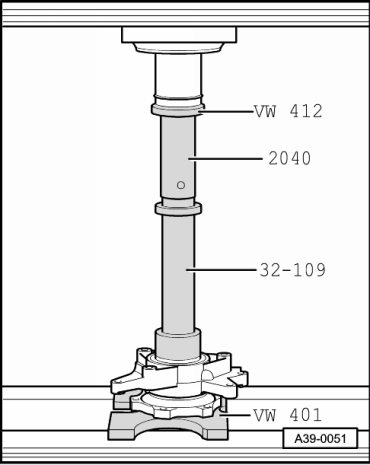

| t | Press tool -VW 412- |

| t | Oil seal extractor lever -VW 681- |

| t | Tube -32 - 109- |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

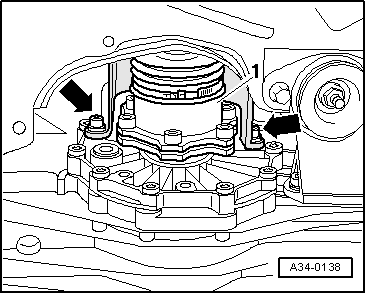

| Component | Nm |

| Bearing bracket for flange shaft (left-side) to gearbox | 23 |

| Heat shield for drive shaft to gearbox | 23 |