| –

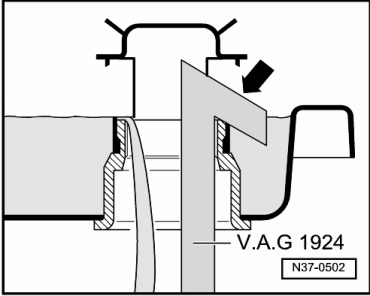

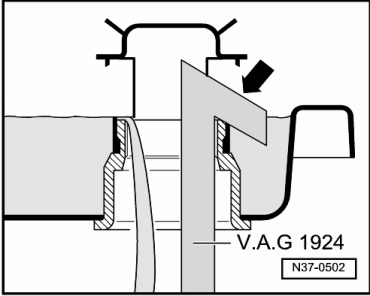

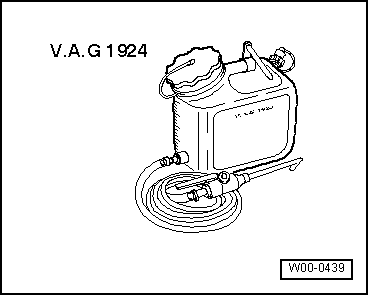

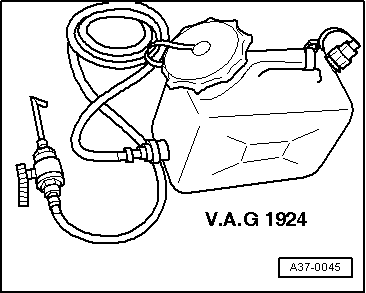

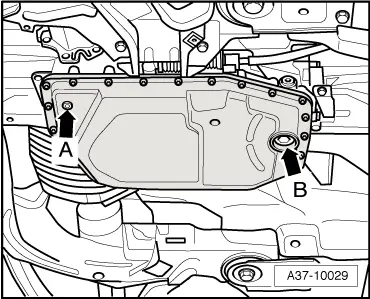

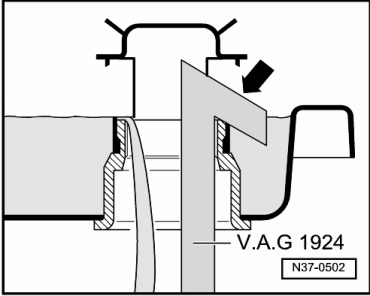

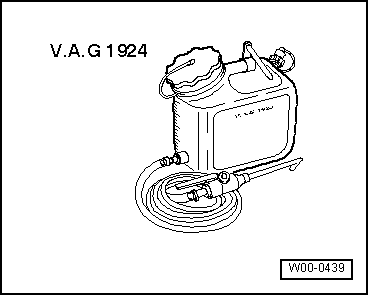

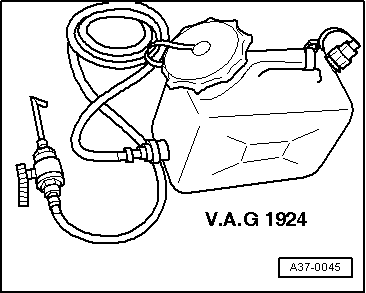

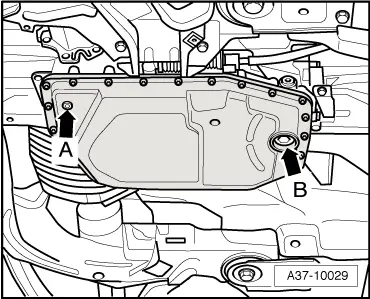

| Guide filler nozzle of ATF charging device -V.A.G 1924- in from below through an opening in the deflector cap -arrow-, taking care not to push the deflector cap upwards out of position. |

| –

| Fill with ATF using ATF filling unit -V.A.G 1924- until ATF comes out of inspection hole. |

| –

| Shift selector lever to position “P”. |

| –

| Start engine and let it idle. |

| –

| Continue filling with ATF using ATF filling unit -V.A.G 1924- until ATF comes out of inspection hole again. |

| –

| Tighten ATF inspection plug. |

| –

| With the engine idling, press the brake pedal and shift the selector lever through all the selector lever positions leaving the selector lever at least 10 seconds in each position. |

| –

| Shift selector lever to position “N”. |

| –

| Increase engine speed to 2000 rpm for at least 60 seconds. |

| –

| Shift selector lever to position “P”. |

Note | Observe all notes and test requirements for “Checking and correcting ATF level”. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note