A4 Mk2

| Removing and installing pinion shaft; dismantling and assembling pinion shaft |

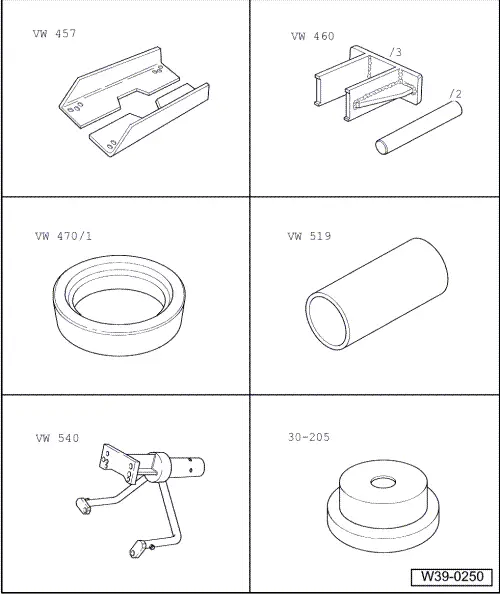

| Special tools and workshop equipment required |

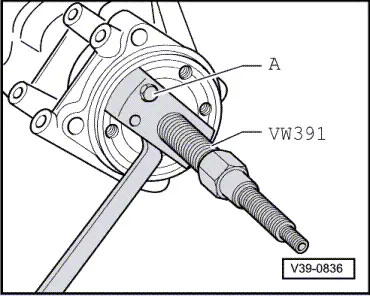

| t | Drive flange installing tool -VW 391- |

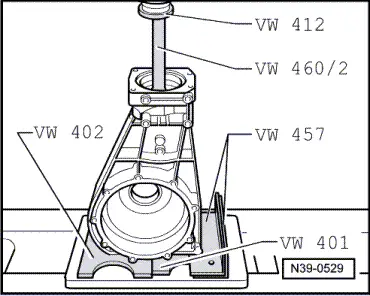

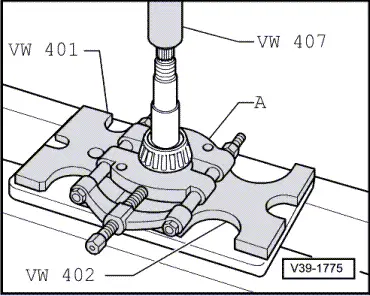

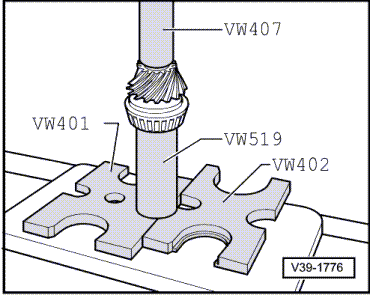

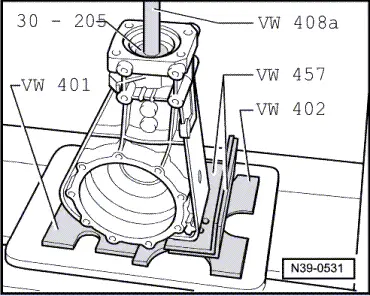

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 407- |

| t | Press tool -VW 408 A- |

| t | Press tool -VW 412- |

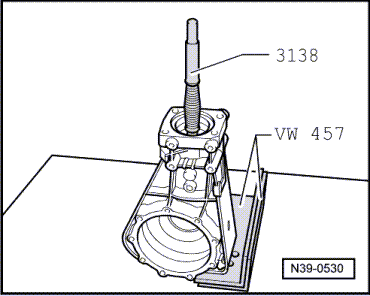

| t | Support rails -VW 457- |

| t | Removing tool -VW 460- |

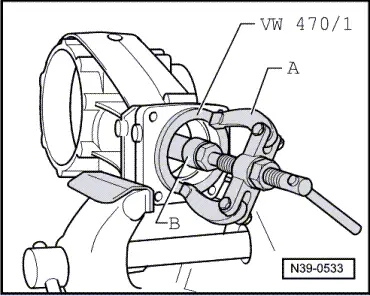

| t | Assembly ring -VW 470/1- |

| t | Tube -VW 519- |

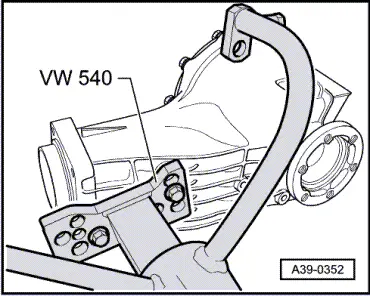

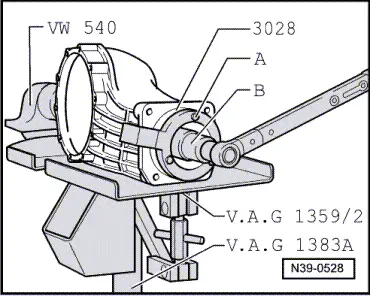

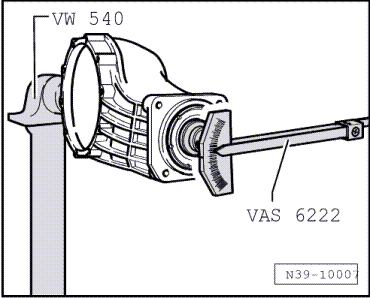

| t | Engine and gearbox support -VW 540- |

| t | Thrust plate -30-205- |

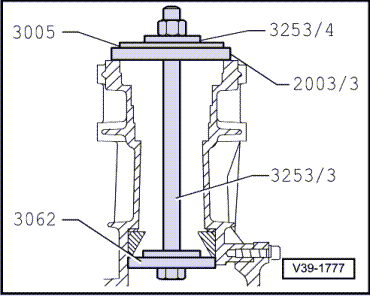

| t | Installing ring -2003/3- |

| t | Thrust plate -3005- |

| t | Counterhold tool -3028- |

| t | Thrust pad -3062- |

| t | Drift -3138- |

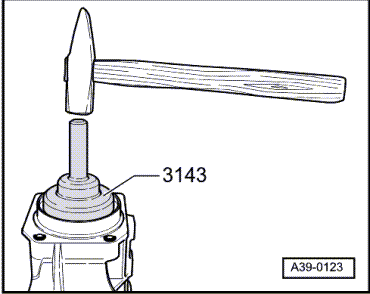

| t | Drift sleeve -3143- |

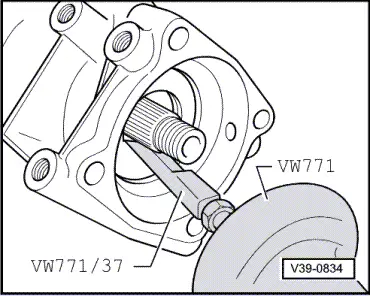

| t | Multi-purpose tool -VW 771- |

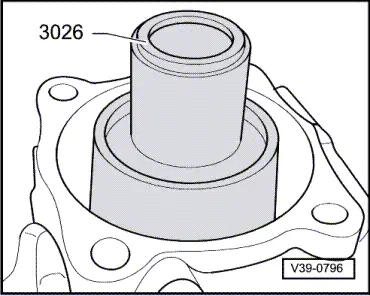

| t | Punch -3026- |

| t | Assembly tool -3253- |

| t | Engine and gearbox jack -V.A.G 1383 A- with universal gearbox support -V.A.G 1359/2- |

| t | Drift -VW 295- |

| t | Friction gauge -VAS 6222- |

| t | Splitter -Kukko 17/2- |

| t | Internal puller -Kukko 21/7- |

| t | Counter-support -Kukko 22/2- |

| t | Sealing grease -G 052 128 A1- |

| t | Socket (long) -SW 36- |

| t | 2 x Hexagon bolts M 8 x 30 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

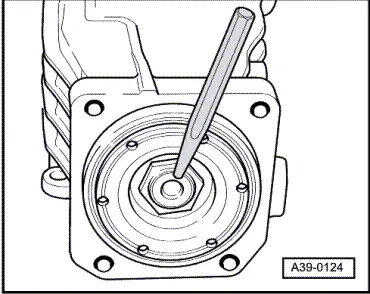

| New bearings | Used bearings → Note |

| 150 … 200 Ncm | 30 … 60 Ncm |

|

|

|

WARNING

WARNING