A4 Mk2

| Removing and installing differential |

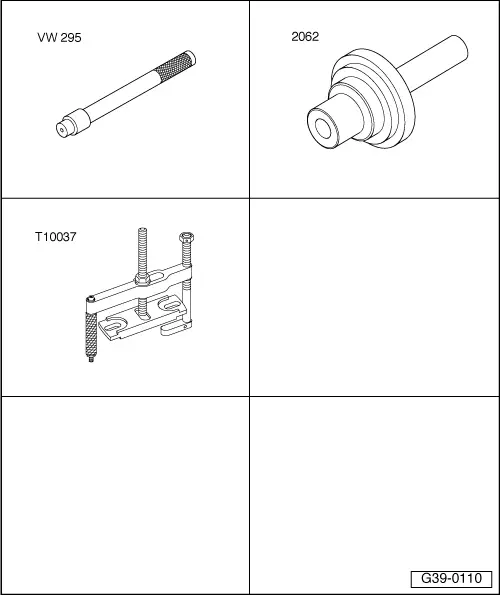

| Special tools and workshop equipment required |

| t | Drift -VW 295- |

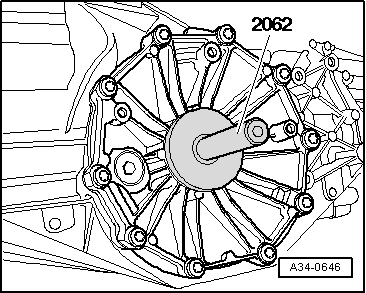

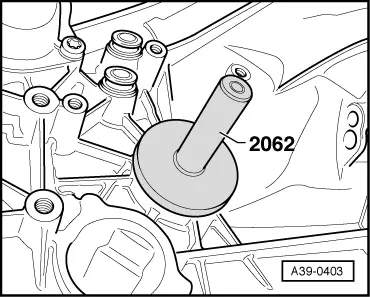

| t | Punch -2062- |

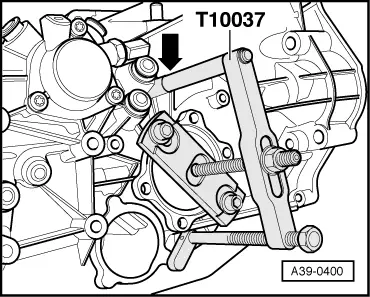

| t | Puller -T10037- |

| t | Sealing grease -G 052 128 A1- |

Note

Note| t | Removing and installing is possible with the gearbox installed. |

| t | The differential can be removed and installed without removing the selector mechanism, input shaft, pinion shaft/hollow shaft or gearbox cover. These components must be removed if the differential needs to be adjusted. |

| t | Adjustment work is required when renewing the parts marked with 1). Table of adjustments → Chapter. |

| 1 - | Gearbox housing 1) |

| 2 - | Oil seal |

| q | Removing → Fig. |

| q | Installing (left-side) → Fig. |

| q | Installing (right-side) → Fig. |

| 3 - | Circlip |

| q | Renew |

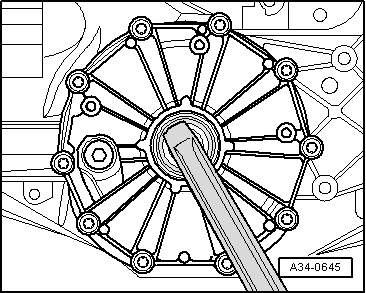

| q | Removing and installing → Fig. |

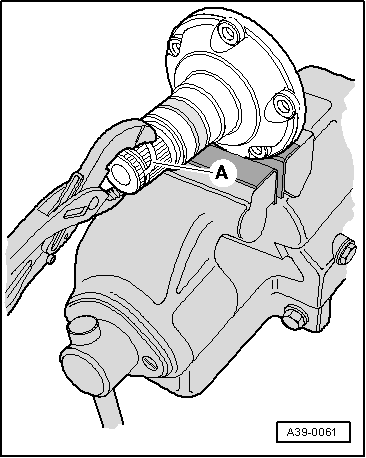

| 4 - | Flange shaft |

| q | Removing (left-side) → Fig. |

| q | Removing (right-side) → Fig. |

| q | Drive in with drift -VW 295- |

| 5 - | Differential with crown wheel1) |

| q | Dismantling and assembling → Chapter |

| 6 - | O-ring |

| q | Always renew |

| q | Lubricate with gear oil |

| 7 - | Cover for final drive1) |

| 8 - | Torx bolt, 24 Nm |

|

|

|

|

|

|

|

|

|

|