A4 Mk2

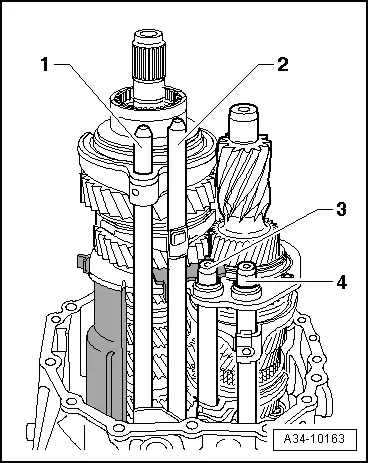

| Removing and installing input shaft, hollow shaft, pinion shaft and selector rods - exploded view |

| 1 - | Bolt, 24 Nm |

| q | Apply locking fluid -AMV 185 101 A1- when fitting |

| 2 - | Leaf spring |

| 3 - | Intermediate piece |

| q | Insert in hole in gearbox housing. |

| 4 - | Clutch release lever |

| q | With release bearing |

| 5 - | Bolt, 24 Nm |

| q | 2 x |

| q | Apply locking fluid -AMV 185 101 A1- when fitting |

| 6 - | Retaining piece |

| q | For guide sleeve |

| 7 - | Guide sleeve |

| q | With oil seal |

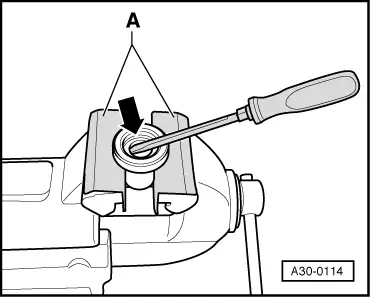

| q | Removing input shaft oil seal → Fig. |

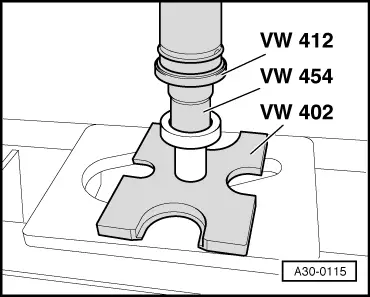

| q | Installing input shaft oil seal → Fig. |

| 8 - | O-ring |

| q | Always renew |

| q | Lubricate with gear oil |

| q | Insert in circumferential groove in gearbox cover |

| 9 - | Circlip |

| q | Insert in circumferential groove in input shaft |

| 10 - | Selector rod for 5th and 6th gear |

| q | Installation position → Fig. |

| q | Only to be renewed complete with pinned selector fork for 5th and 6th gear |

| 11 - | Selector rod for 3rd and 4th gear |

| q | Installation position → Fig. |

| q | Only to be renewed complete with pinned selector fork for 3rd and 4th gear |

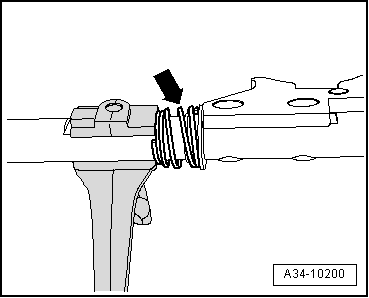

| q | Modification: with spring-loaded selector fork → Fig., allocate via → Electronic parts catalogue “ETKA”. |

| 12 - | Input shaft |

| q | Dismantling and assembling → Chapter |

| 13 - | Bearing mounting |

| q | Clean locking fluid out of tapped holes (using thread tap or similar) |

| q | Pressing out and pressing in ball sleeves for selector rods → Fig. |

Note

Note| t | The roller bearing outer races on the input shaft and hollow shaft cannot be renewed individually. |

| t | The roller bearing outer races must not have any radial clearance in the bearing mounting. |

| 14 - | Bolt, 30 Nm |

| q | 6 x |

| q | Clean thread and apply locking fluid -AMV 185 101 A1- when fitting |

| 15 - | Retaining plate |

| q | Installation position: machined side faces towards gearbox housing (can only be installed in one position). |

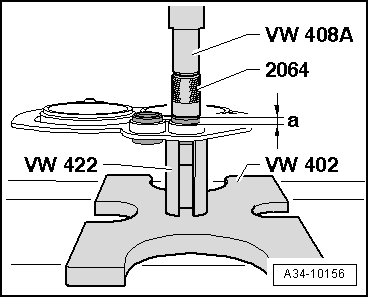

| 16 - | Shim “S4” |

| q | Table of adjustments → Chapter |

| 17 - | Pinion shaft |

| q | With double angular contact ball bearing and tapered roller bearing inner race |

| q | Dismantling and assembling → Chapter |

| 18 - | Needle bearing |

| q | For pinion shaft/hollow shaft |

| 19 - | Shim “S3” |

| q | Table of adjustments → Chapter |

| 20 - | Hollow shaft |

| q | With pressed-on gears for 5th and 6th gear |

| q | Dismantling and assembling → Chapter |

| 21 - | Oil guide panel |

| 22 - | Gearbox housing |

| q | With differential and flange shafts |

Note

Note

|

|

|

|

Note

Note

|

|

|

|