A4 Mk2

| Dismantling and assembling Torsen housing |

| Special tools and workshop equipment required |

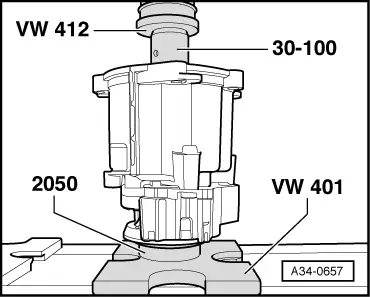

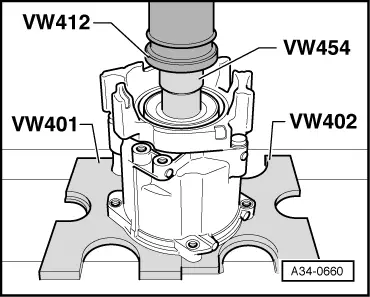

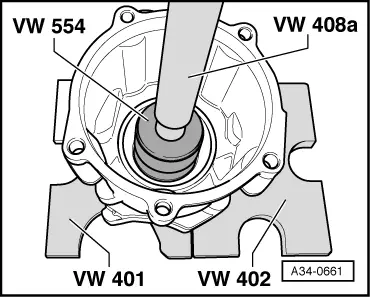

| t | Thrust plate -VW 401- |

| t | Thrust plate -VW 402- |

| t | Press tool -VW 408 A- |

| t | Press tool -VW 412- |

| t | Press tool -VW 454- |

| t | Press tool -VW 554- |

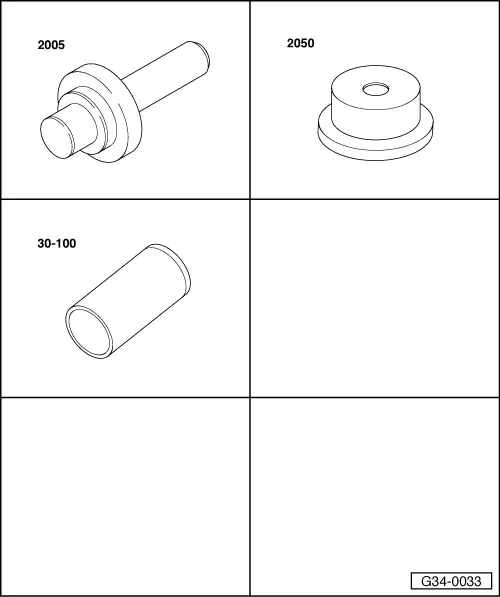

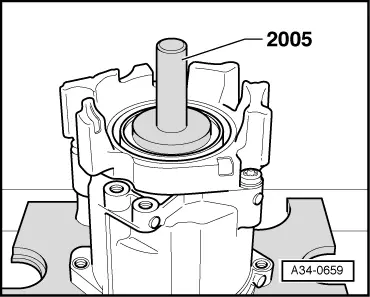

| t | Punch -2005- |

| t | Thrust piece -2050- |

| t | Drift sleeve -30 - 100- |

| t | Torque wrench -V.A.G 1331- |

| t | Extractor tool -T20143- |

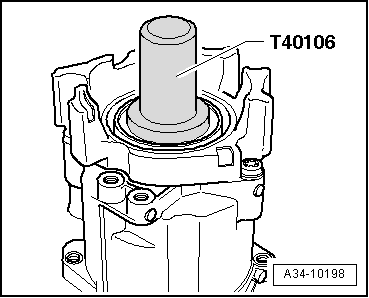

| t | Thrust piece -T40106- |

| t | Shim -016 311 391 A- |

| t | Locking fluid -AMV 185 101 A1- |

| t | Sealing grease -G 052 128 A1- |

Note

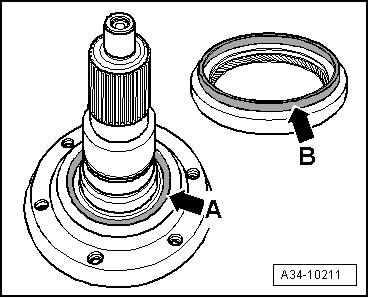

Note| Due to the introduction of an oil seal with additional dust lip (from serial no. 42987) → Fig., the flange shaft → Item was fitted with a groove. Refer to → Electronic parts catalogue “(ETKA)” to allocate components. |

| 1 - | Flange shaft |

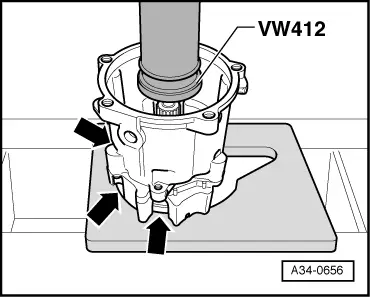

| q | Pressing out → Fig. or → Fig. |

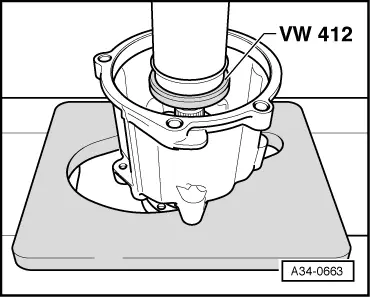

| q | Pressing in → Fig. |

| q | Modification: from serial no. 42987 with groove → Fig. |

| q | Select components from → Electronic parts catalogue “ETKA”. |

| 2 - | Bolt, 20 Nm + 90° |

| q | For vibration damper |

| q | 3 x |

| q | Self-locking |

| q | Renew |

| 3 - | Vibration damper |

| q | Not fitted on all versions |

| 4 - | Oil seal |

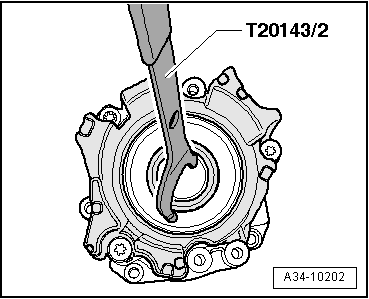

| q | Removing → Fig. |

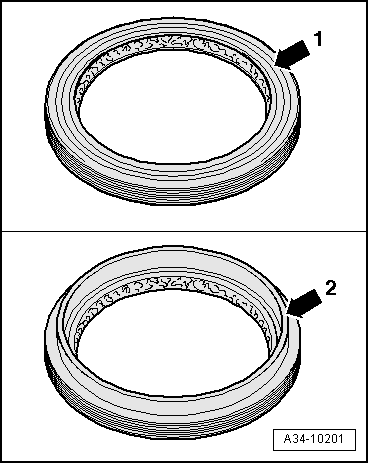

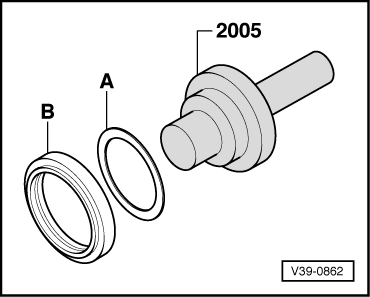

| q | Installation up to serial no. 42986 → Fig. |

| q | Modification: with additional dust lip from serial no. 42987 onwards → Fig. |

| q | Installation from serial no. 42987 onwards → Fig. |

| 5 - | Torsen housing |

| q | Removing and installing (with gearbox removed) → Chapter |

| q | Removing and installing is also possible with gearbox installed in vehicle → 6-speed manual gearbox 0A3, four-wheel drive; Rep. Gr.34 |

| 6 - | Ball bearing |

| q | For flange shaft |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| 7 - | Circlip |

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|