A4 Mk2

| Removing engine |

| Special tools and workshop equipment required |

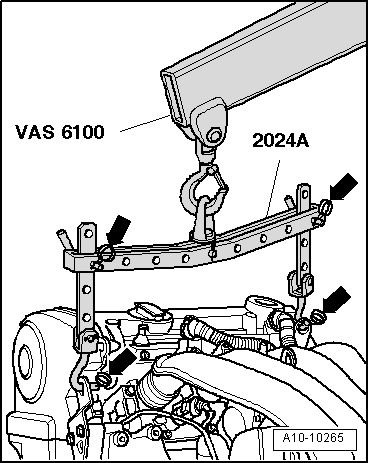

| t | Lifting tackle -2024 A- |

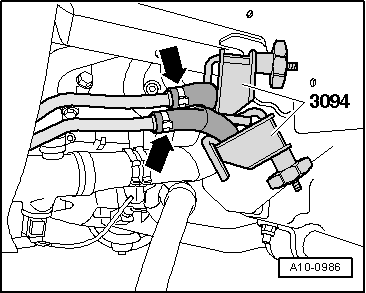

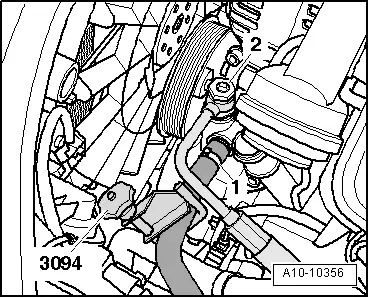

| t | Hose clamps for hoses up to 25 mm Ø -3094- |

| t | Used oil collection and extraction unit -V.A.G 1782- |

| t | Hose clip pliers -V.A.G 1921- |

| t | Spark plug connector pliers -V.A.G 1922- |

| t | Workshop hoist -VAS 6100- or -V.A.G 1202 A- |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

Note

Note

Note

Note

|

|

Caution

Caution WARNING

WARNING