A4 Mk2

| Removing and installing sealing flange (front) |

| Special tools and workshop equipment required |

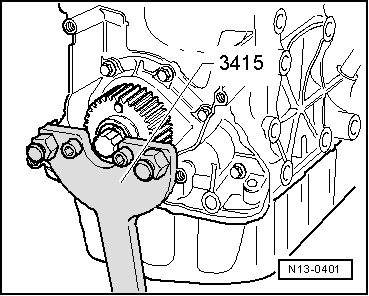

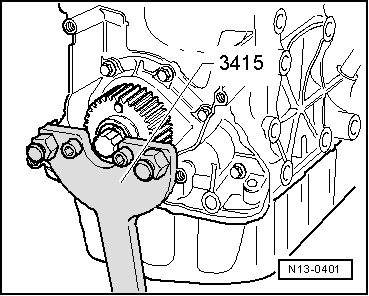

| t | Counterhold tool -3415- |

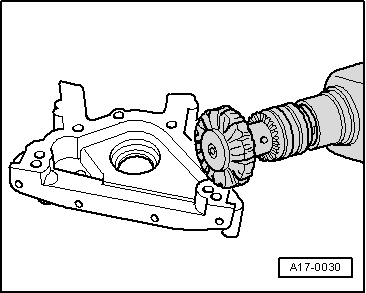

| t | Assembly tool -T10053- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Electric drill with plastic brush attachment |

| t | Safety goggles |

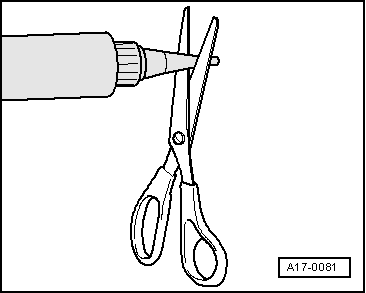

| t | Sealant → Parts catalogue |

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

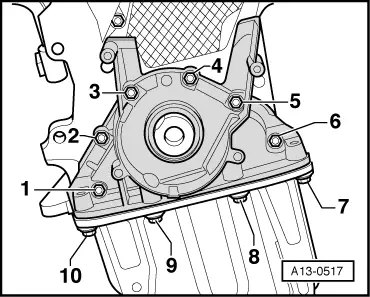

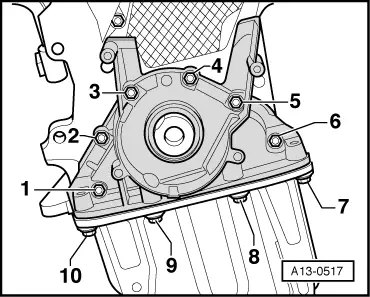

| Component | Nm | |||||

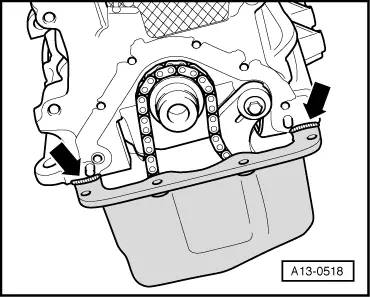

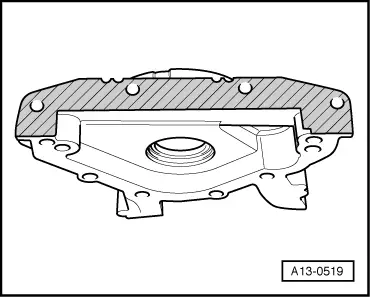

| Sealing flange to cylinder block | 15 | |||||

| Toothed belt sprocket to crankshaft | 90 + 90° 1)2) | |||||

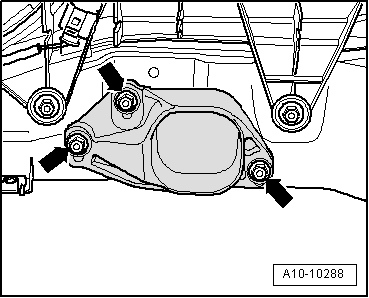

| Stop for torque reaction support | 28 | |||||

| ||||||

Note

Note

|

WARNING

WARNING