A4 Mk2

|

Note

Note |

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

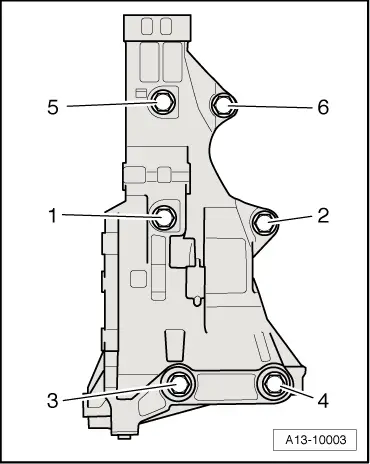

| Component | Nm | ||||

| Bracket for ancillaries to cylinder block | 45 | ||||

| Idler roller for toothed belt to bracket for ancillary units | 40 + 90° 1)2) | ||||

| Stop for torque reaction support to lock carrier | 28 | ||||

| Hose clips (9 mm wide) | 3 | ||||

| Hose clips (13 mm wide) | 5.5 | ||||

| |||||

Caution

Caution