A4 Mk2

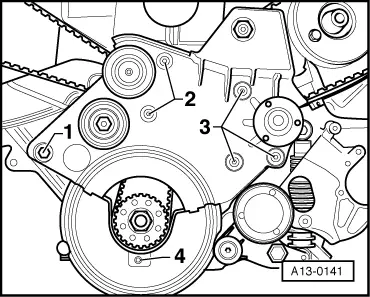

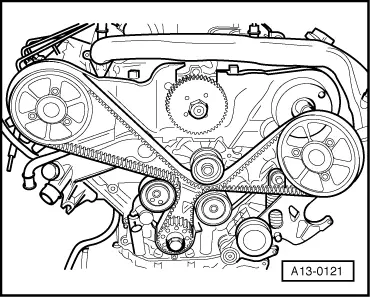

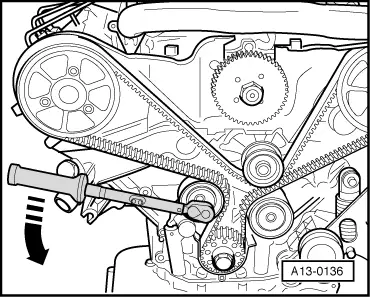

| Removing and installing toothed belt |

| Special tools and workshop equipment required |

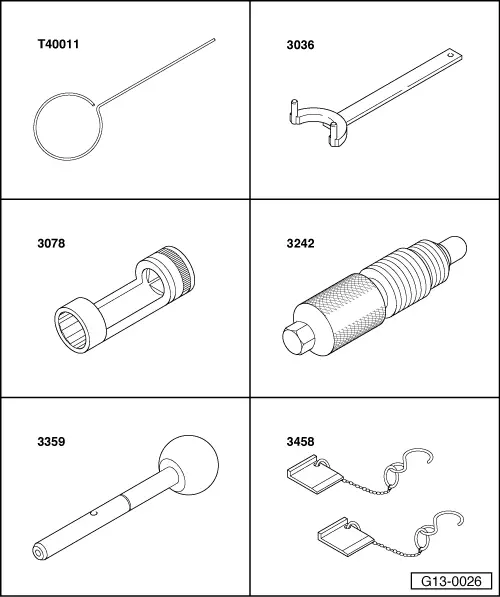

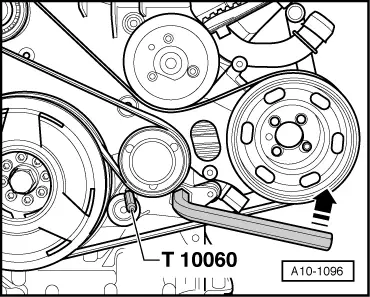

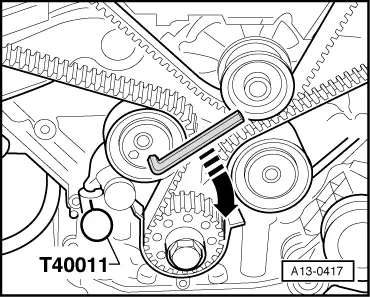

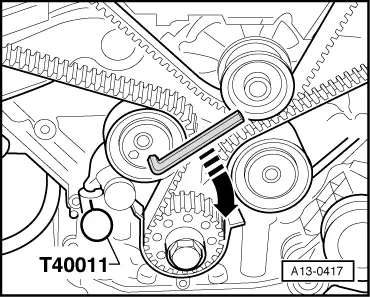

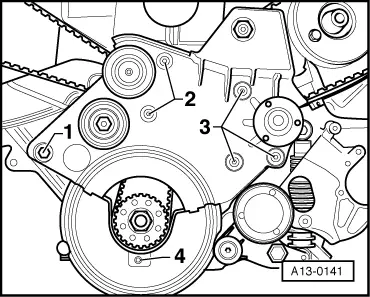

| t | Locking pin -T40011- |

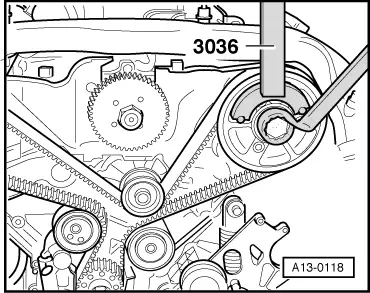

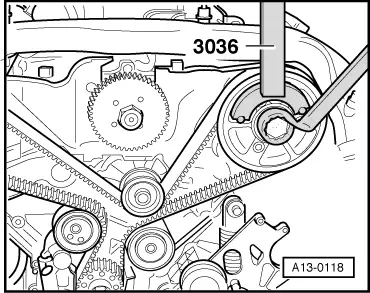

| t | Counterhold tool -3036- |

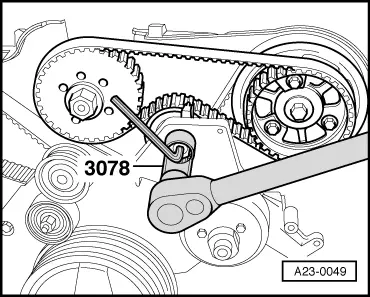

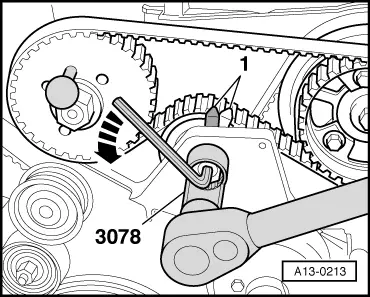

| t | Socket (22 mm) -3078- |

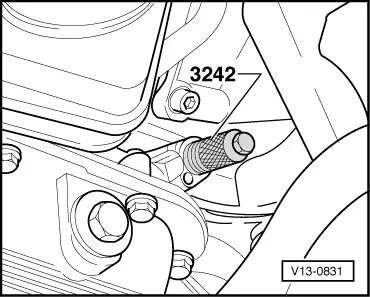

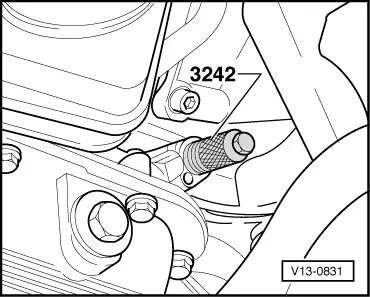

| t | Locking pin -3242- |

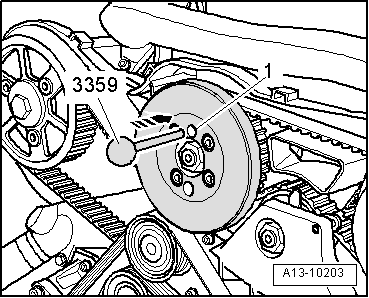

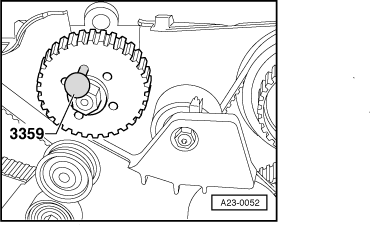

| t | Diesel injection pump locking pin -3359- |

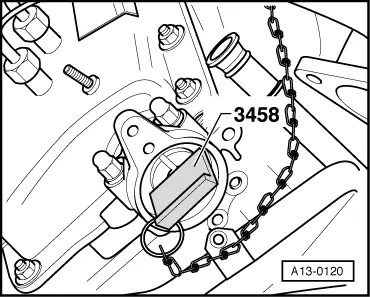

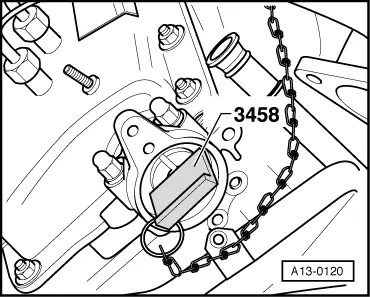

| t | Camshaft clamp -3458- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

Note

Note |

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

| Component | Nm |

| Camshaft sprocket to camshaft | 75 |

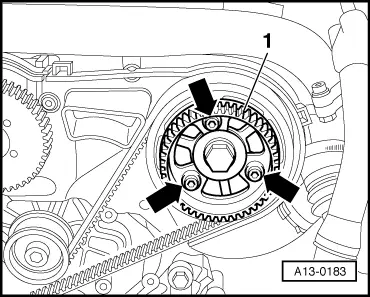

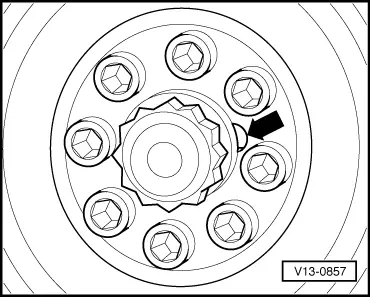

| Vibration damper to injection pump sprocket | 22 |

| Drive sprocket for injection pump to camshaft | 22 |

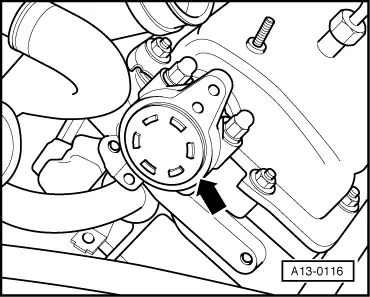

| Tensioning roller for injection-pump toothed belt to bracket for viscous fan | 36 |

| Exhauster pump to cylinder head | 10 |

| Vibration damper to crankshaft sprocket | 22 |

| Screw plug in cylinder block | 35 |

| Torque reaction support to top section of sump | 40 |

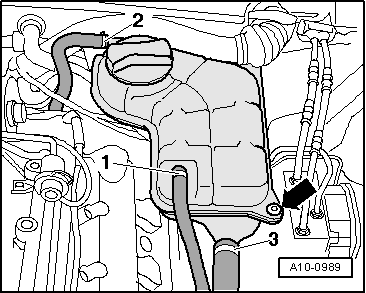

| Hose clips (9 mm wide) | 3 |

| Hose clips (13 mm wide) | 5.5 |

Caution

Caution WARNING

WARNING