A4 Mk2

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

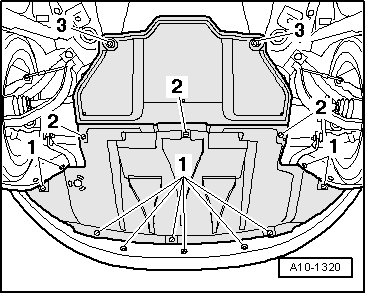

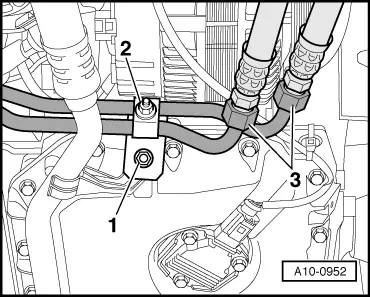

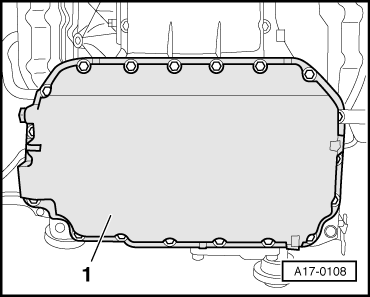

| Component | Nm | ||

| Sump (bottom section) to sump (top section) | 10 1) | ||

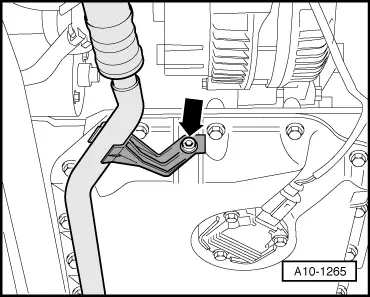

| Bracket to sump | 9 | ||

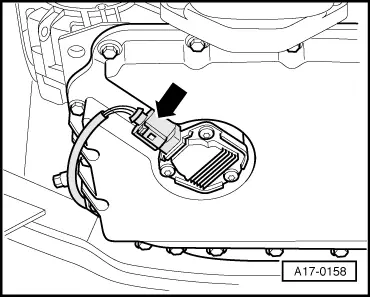

| Oil drain plug | 30 | ||

| |||

WARNING

WARNING