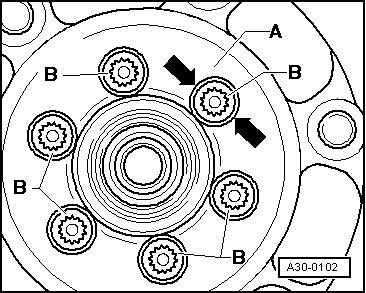

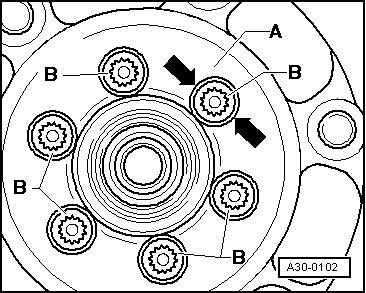

| To prevent damage to the dual-mass flywheel when removing, the bolts -B- must not be removed with an impact wrench or similar. The bolts may only be removed by hand using conventional tools. |

| –

| Rotate the dual-mass flywheel -A- so that the bolts align with the holes -arrows-. |

| –

| When unscrewing the bolts, make sure that the bolt heads do not come into contact with the dual-mass flywheel; the flywheel will otherwise be damaged as the bolts are screwed out. |

| Installation is carried out in the reverse order; note the following: |

Note | t

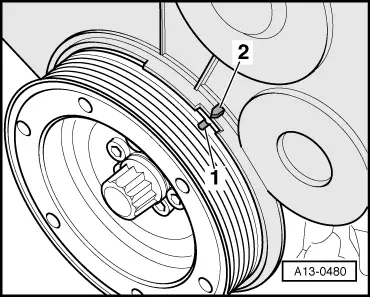

| A needle bearing is fitted in the dual-mass flywheel; knock in the needle bearing when fitting a new flywheel → Chapter. |

| –

| Use new securing bolts. |

| –

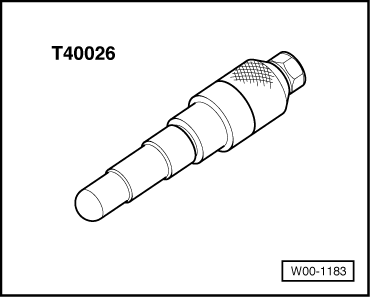

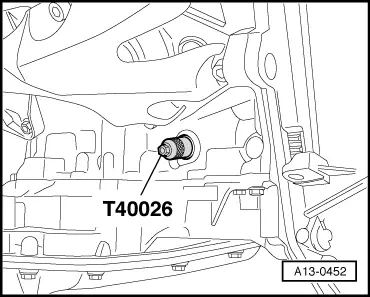

| Remove locking pin -T40026- and screw plug for TDC marking into cylinder block together with new O-ring. |

|

|

|

Note

Note

Note

Note

Caution

Caution