A4 Mk2

| Removing engine |

| Special tools and workshop equipment required |

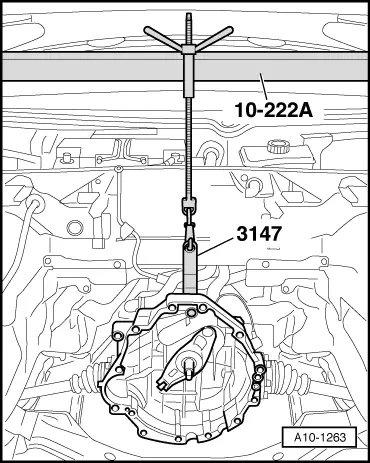

| t | Support bracket -10-222 A- |

| t | Removal lever -80-200- |

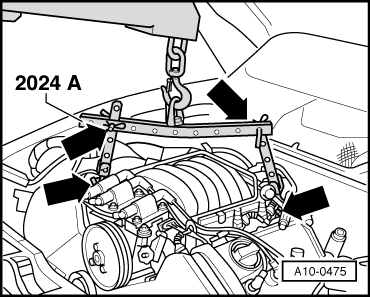

| t | Lifting tackle -2024 A- |

| t | Gearbox support -3147- |

| t | Drip tray -V.A.G 1306- |

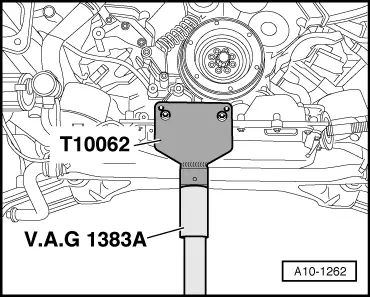

| t | Engine and gearbox jack -V.A.G 1383 A- |

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

Note

Note

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

Note

Note

Note

Note

|

|

Caution

Caution WARNING

WARNING