A4 Mk2

| Removing and installing sump (top section) |

| Special tools and workshop equipment required |

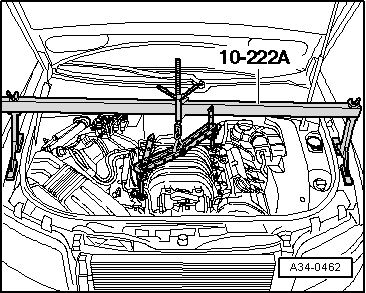

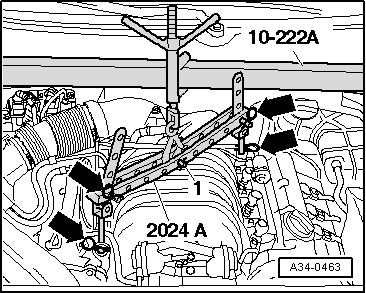

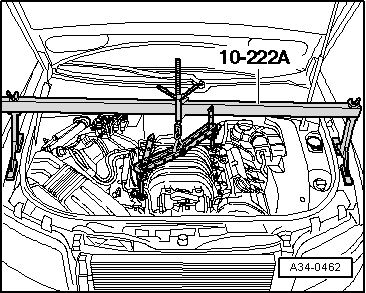

| t | Support bracket -10-222 A- |

| t | Removal lever -80-200- |

| t | Lifting tackle -2024 A- |

| t | U/J extension and socket, 10 mm -3220- |

| t | Drip tray -V.A.G 1306- |

| t | Drip tray |

| t | Electric drill with plastic brush attachment |

| t | Safety goggles |

| t | Sealant → Parts catalogue |

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

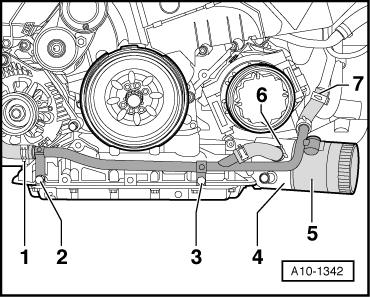

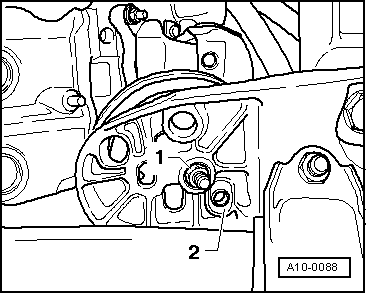

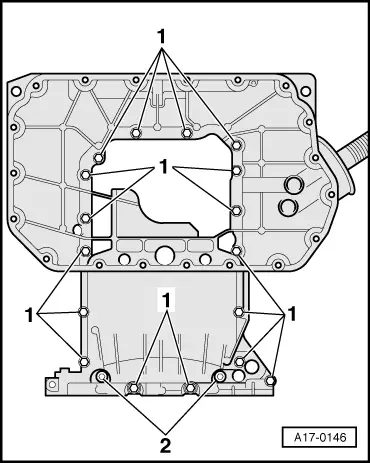

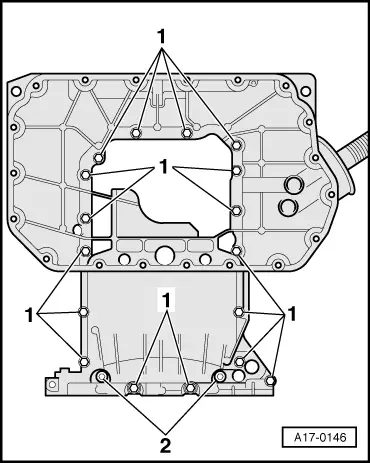

| Component | Nm | |

| Sump (top section) to: | M7 | 16 |

| Cylinder block and sealing flanges | M8 | 22 |

| Sump (top section) to gearbox | 45 | |

| Bracket for noise insulation to subframe | 10 | |

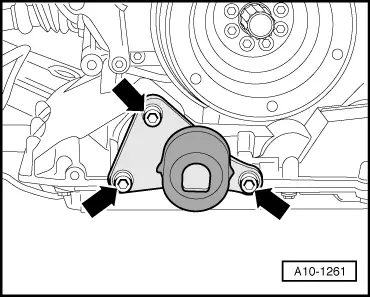

| Engine mounting to subframe | 23 | |

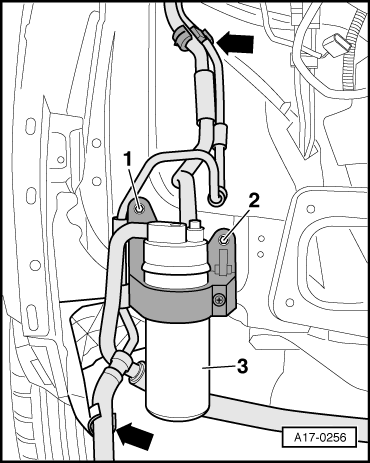

| Reservoir bracket to body | 10 | |

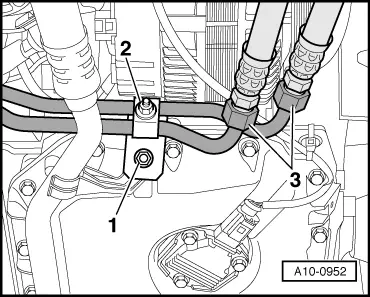

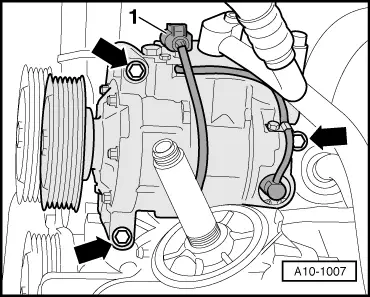

| Refrigerant line bracket to sump | 10 | |

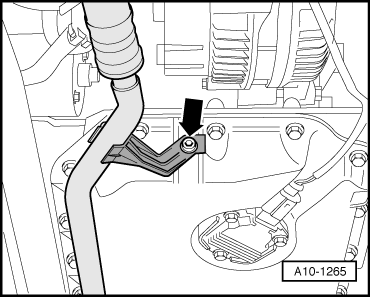

| Secondary air pump bracket to longitudinal member | 10 | |

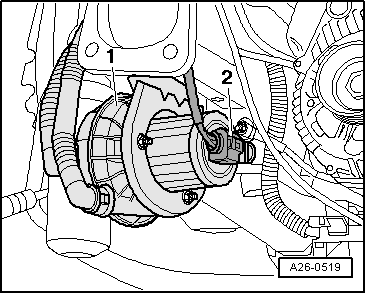

| Oil cooler to sump (top section) | 30 | |

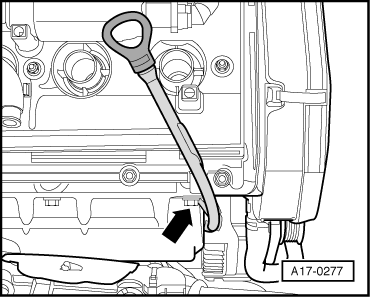

| Guide tube for dipstick to cylinder head | 22 | |

Caution

Caution WARNING

WARNING