A4 Mk2

| Removing and installing camshaft timing chain |

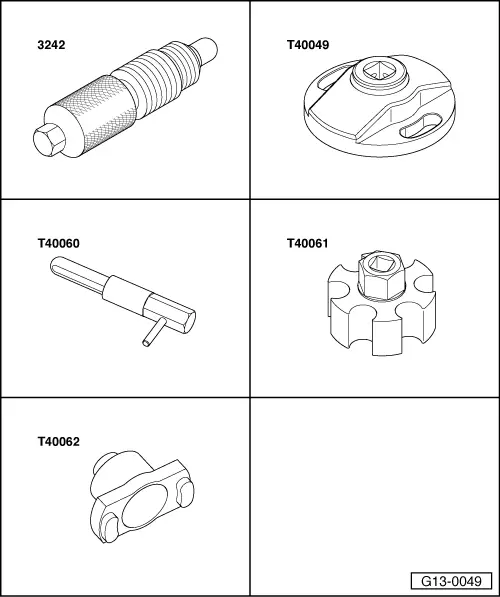

| Special tools and workshop equipment required |

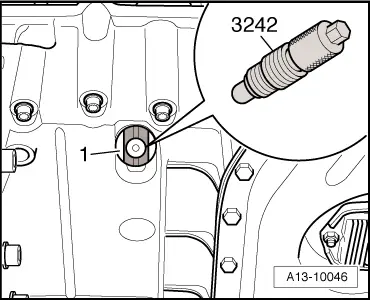

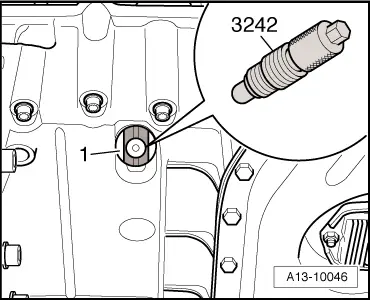

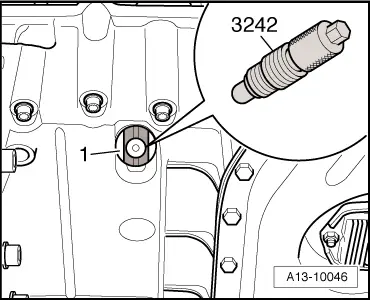

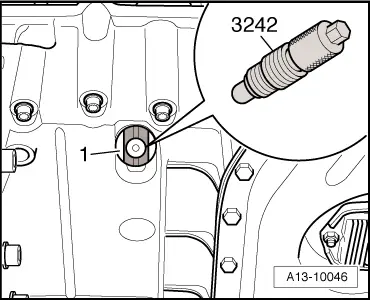

| t | Locking pin -3242- |

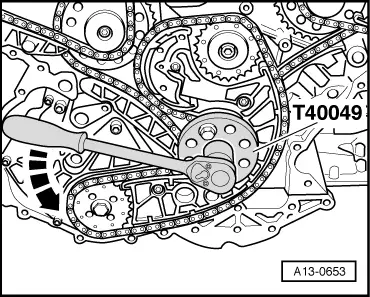

| t | Special wrench -T40049- |

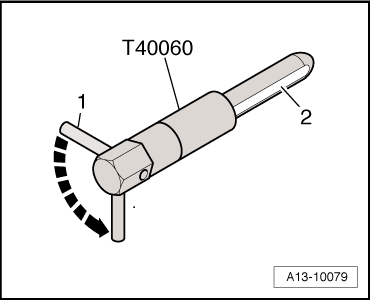

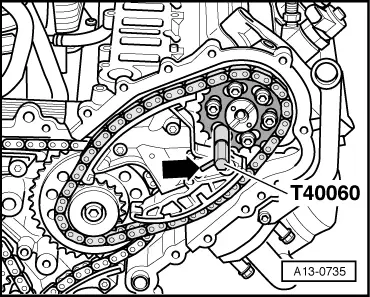

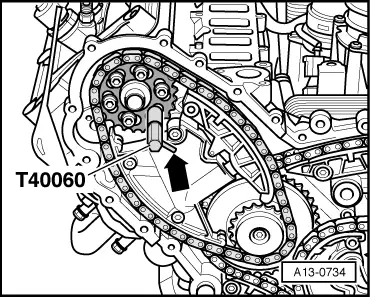

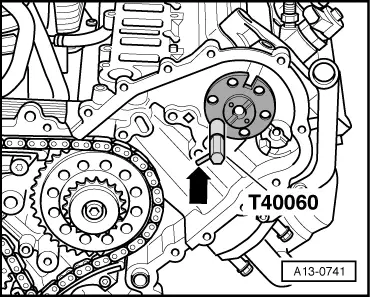

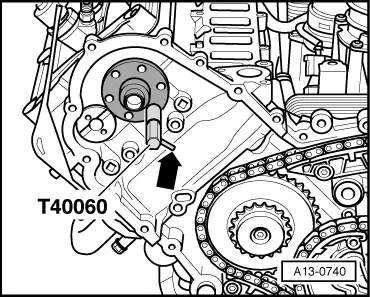

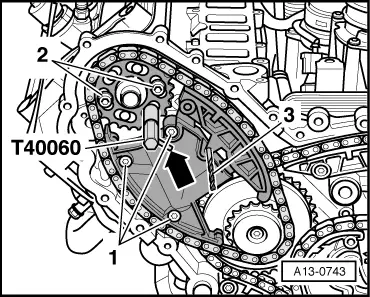

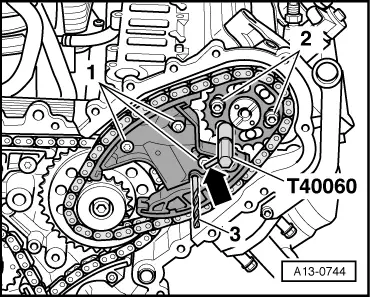

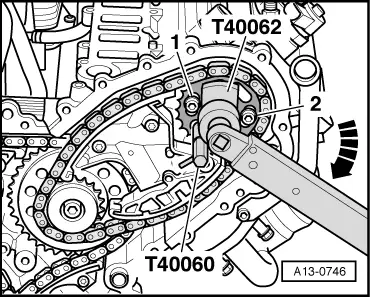

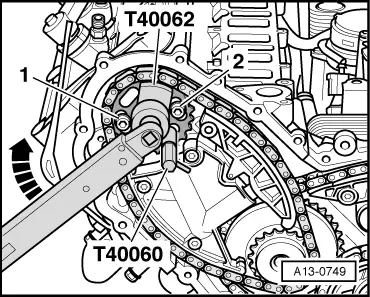

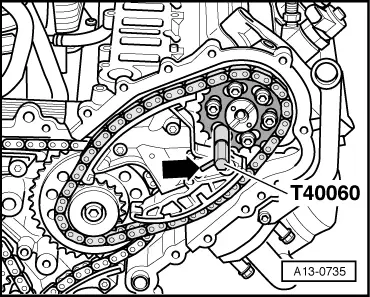

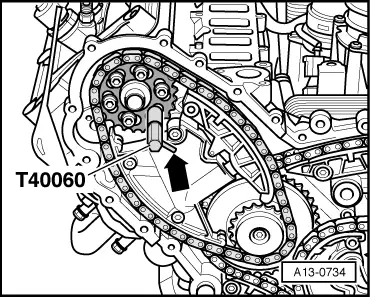

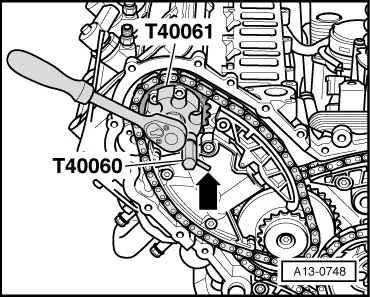

| t | 2x Adjustment pin -T40060- |

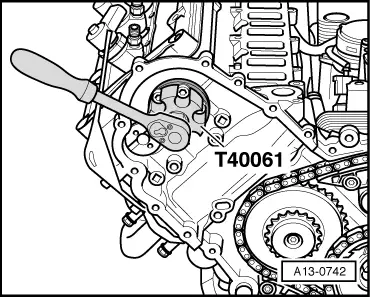

| t | Adapter -T40061- |

| t | Adapter -T40062- |

| t | Drill bit 3.3 mm Ø (2x) |

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Component | Nm | ||||

| Chain tensioner to cylinder head | 5 + 90° 1)2) | ||||

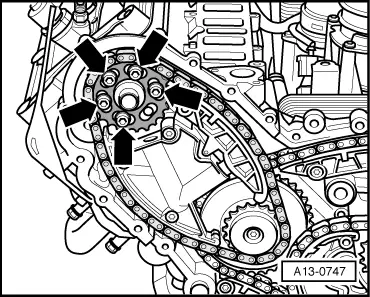

| Camshaft sprocket to camshaft | 23 | ||||

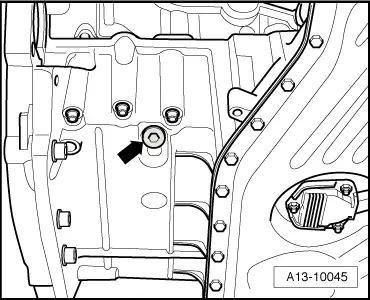

| Screw plug in top section of sump | 35 | ||||

| |||||

Caution

Caution WARNING

WARNING