| –

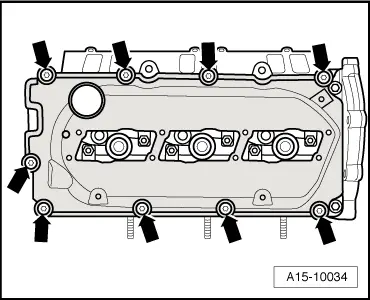

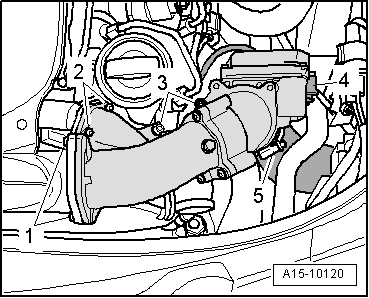

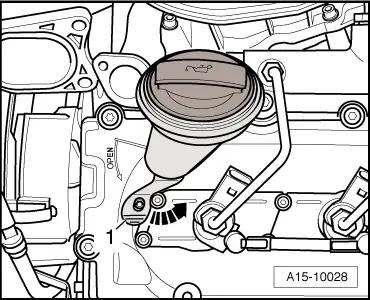

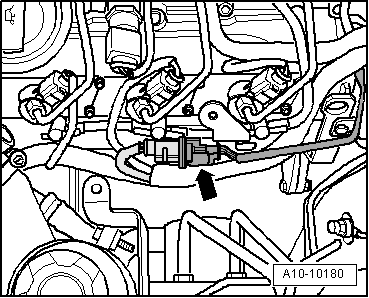

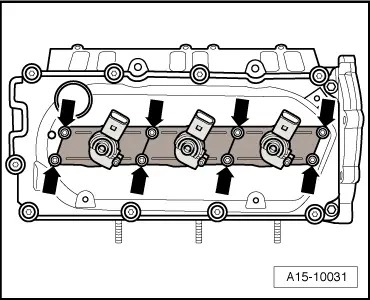

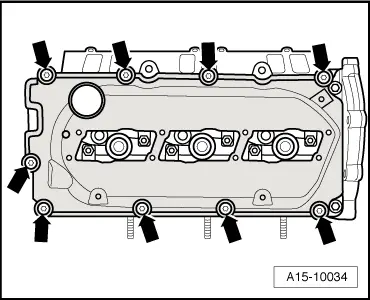

| Loosen cylinder head cover bolts -arrows- in diagonal sequence. |

| –

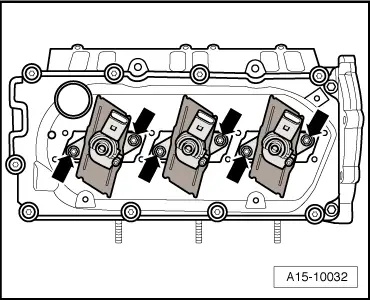

| Remove bolts and take off cylinder head cover. |

| Installation is carried out in the reverse order; note the following: |

Note | t

| Renew gaskets and bolts for cylinder head cover if damaged. |

| t

| Renew gaskets, seals and O-rings. |

| t

| Hose connections and hoses for charge air system must be free of oil and grease before assembly. |

| t

| To ensure that the charge air hoses can be properly secured at their connections, spray rust remover onto the worm thread of used hose clips before installing. |

| –

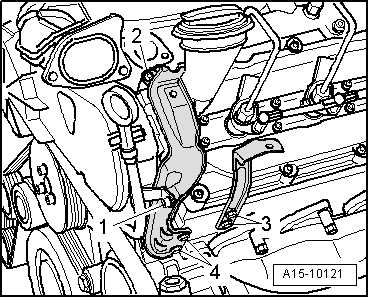

| Tighten cylinder head cover bolts diagonally and in stages. |

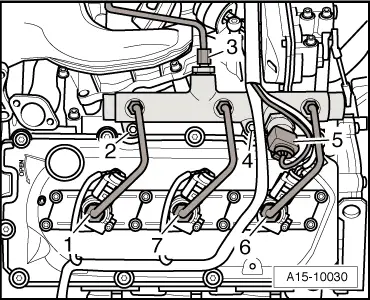

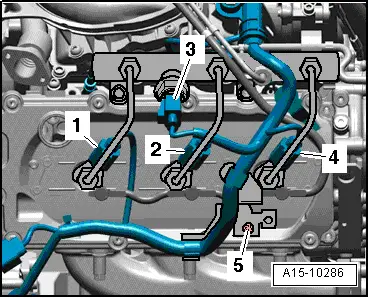

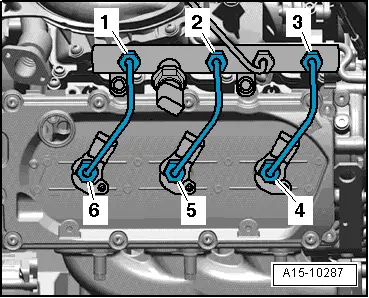

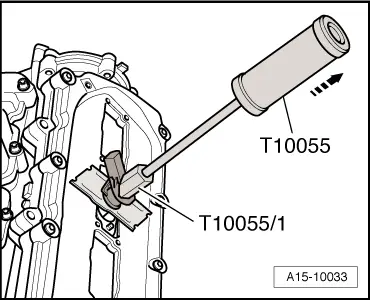

| Instructions for installing injectors: |

| l

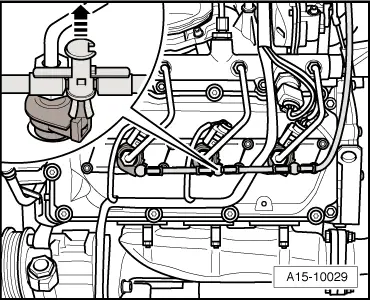

| Before installation, make sure the injectors and their surroundings are clean. If necessary use a clean cloth to wipe out the injector slot, taking care not to cause damage (do not use sharp-edged tools). |

| l

| Always install new seals and gaskets. Lubricate all seals and gaskets lightly with engine oil or assembly oil before installing. |

| l

| The injectors must be completely undamaged. To remove the old copper seal from the injector, clamp the seal carefully in a vice so that it is just held between the jaws without turning. Then carefully pull and twist the injector out of the copper seal by hand. |

| l

| When an injector is renewed, also renew the injector pipe and clamping piece at the same time. |

| l

| Used injectors and injector pipes may only be re-installed on the same cylinder. |

|

|

|

Note

Note

Note

Note

Caution

Caution