A4 Mk2

| Removing and installing subframe |

| Special tools and workshop equipment required |

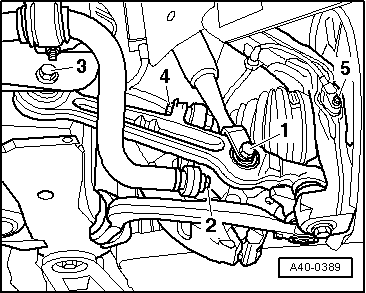

| t | Support bracket -10 - 222 A- |

| t | Rack -10 - 222 A /1- |

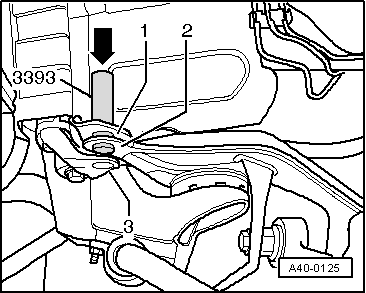

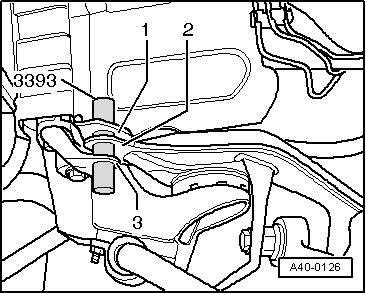

| t | Mandrels -3393- |

| t | Torque wrench -V.A.G 1331- |

| t | Torque wrench -V.A.G 1332- |

| t | Engine and gearbox jack -V.A.G 1383 A- |

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|