A4 Mk3

| Removing gearbox – vehicles with 1.8 ltr. and 2.0 ltr. TFSI engine |

| Special tools and workshop equipment required |

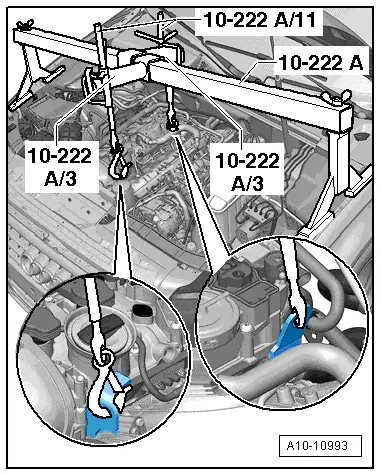

| t | Support bracket -10 - 222 A- |

| t | Ring spanner insert, 16 mm -V.A.G 1332/14- |

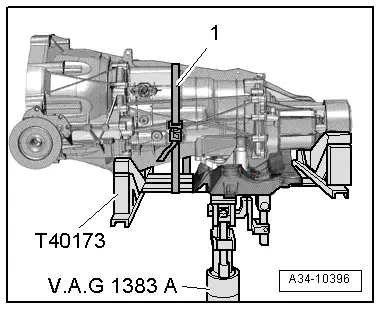

| t | Engine and gearbox jack -V.A.G 1383 A- |

| t | Stepladder -VAS 5085- |

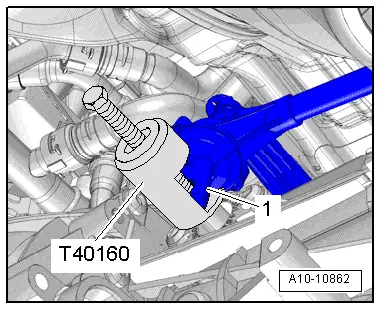

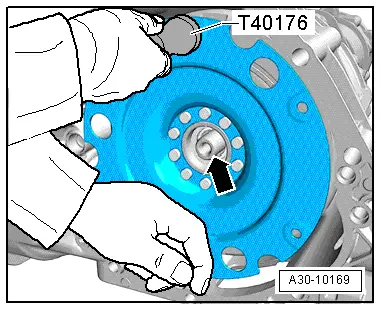

| t | Puller -T40160- |

| t | Gearbox support -T40173- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

Caution

Caution