A4 Mk3

| Exploded view - servicing gearbox housing |

| Special tools and workshop equipment required |

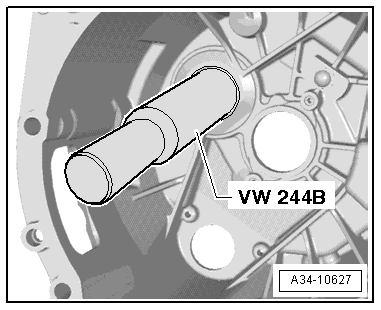

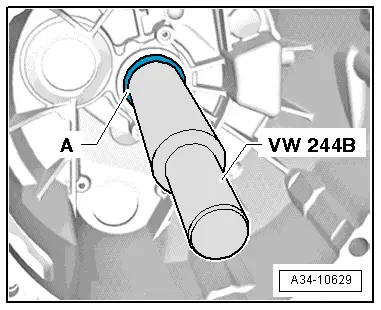

| t | Drift sleeve -VW 244 B- |

| t | Multi-purpose tool -VW 771- |

| t | Mandrel -30 - 505- |

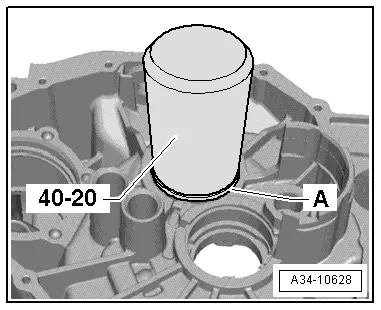

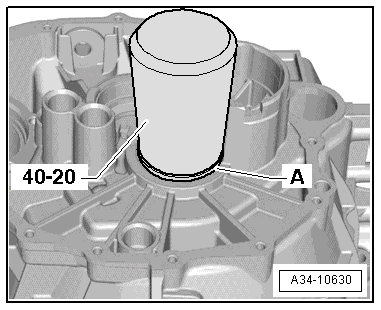

| t | Drift sleeve -40 - 20- |

| t | -1-Internal puller -Kukko 21/3- |

| t | Lubricating paste -G 000 150- |

Note

Note| t | At present there is no provision for dismantling and assembling the differential. |

| t | At present there is no provision for removing and installing the pinion shaft. |

| t | At present there is no provision for adjusting the pinion shaft and crown wheel. |

| t | Replacement: renew gearbox housing together with installed pinion shaft and differential. |

| 1 - | Intermediate piece |

| q | Renew if damaged |

| 2 - | Ball-head pin |

| q | 25 Nm |

| q | Grease bearing surface for clutch release lever with lubricating paste -G 000 150- |

| 3 - | Cap |

| q | For gearbox breather |

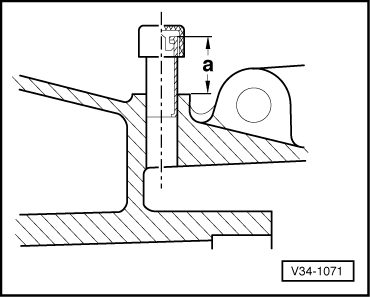

| 4 - | Breather pipe |

| q | Installation depth → Fig. |

| q | Clip in cap for gearbox breather |

| 5 - | Oil seal |

| q | For flange shaft (left-side) |

| q | Removing and installing → Chapter |

| 6 - | Differential |

| q | Can currently only be renewed together with gearbox housing and pinion shaft |

Note

Note| Differential bevel gears cannot be removed and installed |

| 7 - | O-ring |

| q | Always renew |

| q | Lubricate with gear oil |

| 8 - | Cover for final drive |

| q | Renewing → Chapter |

| 9 - | Bolt |

| q | 20 Nm and then turn 90° further |

| q | Steel bolts (M8; 38 mm long) |

| q | 10x |

| 10 - | Flange shaft (right-side) |

| q | With circlip |

| q | Removing and installing → Chapter |

| 11 - | Oil seal |

| q | For flange shaft (right-side) |

| q | Removing and installing → Chapter |

| 12 - | Oil collector |

| 13 - | Pinion shaft |

| q | Can currently only be renewed together with gearbox housing and differential |

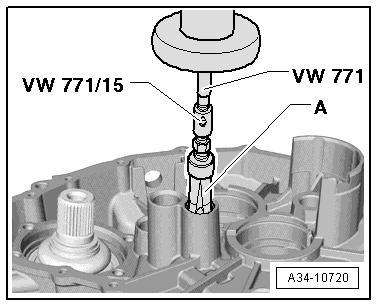

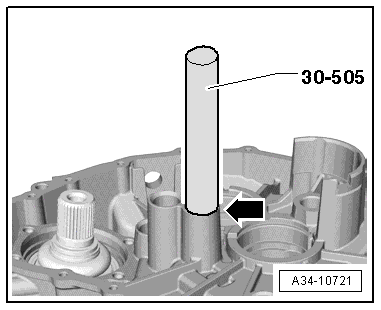

| 14 - | Bearing bush |

| q | For selector plate / selector fork |

| q | 3x |

| q | Removing → Fig. |

| q | Installing → Fig. |

| 15 - | Ball bearing |

| q | For output shaft |

| q | Driving out → Fig. |

| q | Driving in → Fig. |

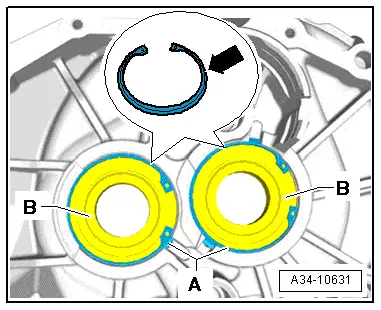

| 16 - | Circlip |

| q | Installation position → Fig. |

| 17 - | Circlip |

| q | Installation position → Fig. |

| 18 - | Ball bearing |

| q | For input shaft |

| q | Driving out → Fig. |

| q | Driving in → Fig. |

| 19 - | Magnet |

| q | Clean |

| 20 - | Oil drain plug |

| q | 45 Nm |

| 21 - | Gearbox housing |

| q | Can currently only be renewed together with differential and pinion shaft |

|

|

|

|

|

|

|

|

|

|

|

|

|

|