| –

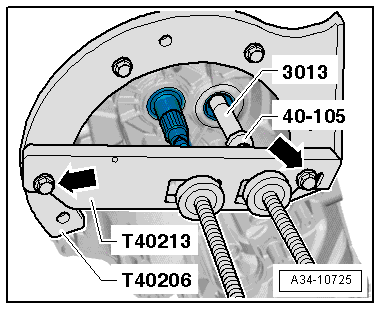

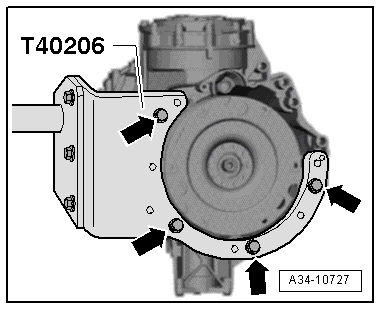

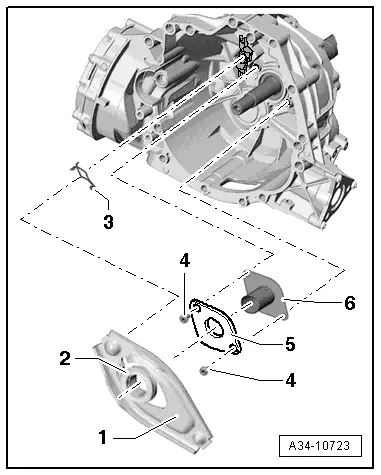

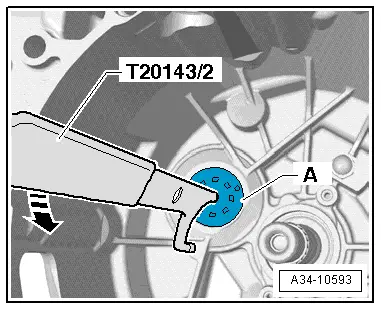

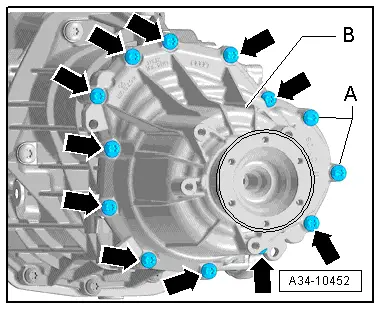

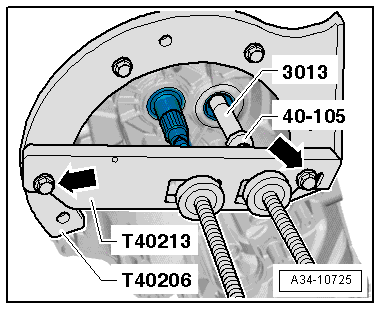

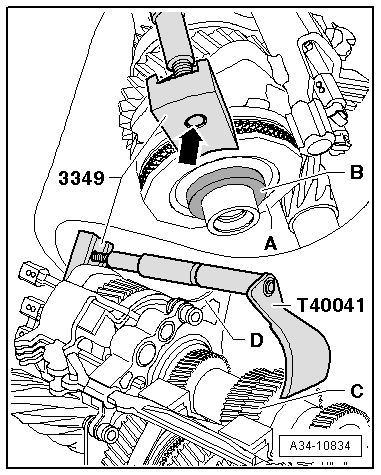

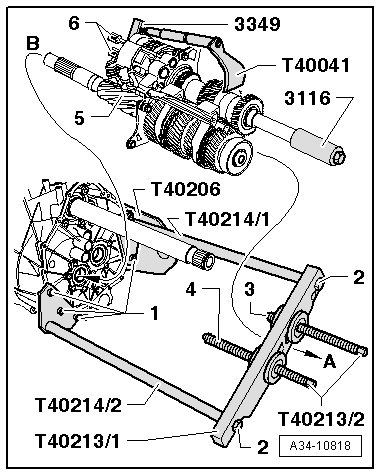

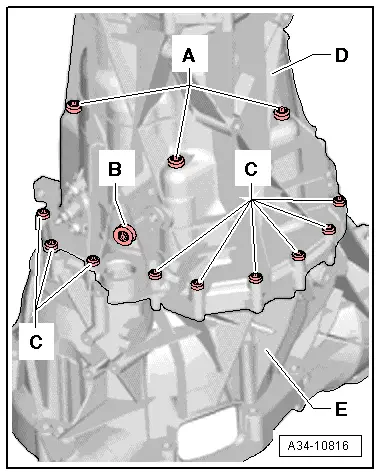

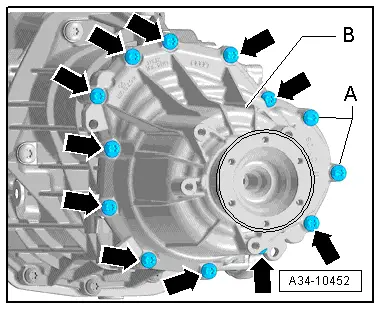

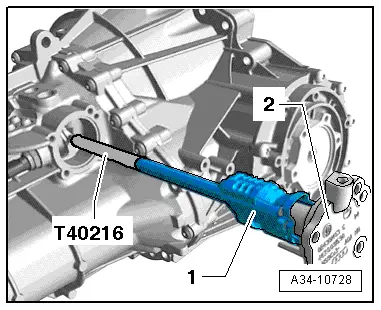

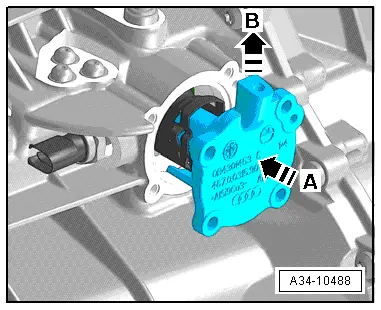

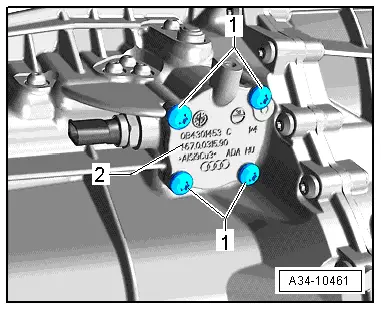

| Attach separating tool -T40213- to gearbox support -T40206- with bolts -arrows-. |

Caution | Risk of damage to gears, shafts and bearings. |

| t

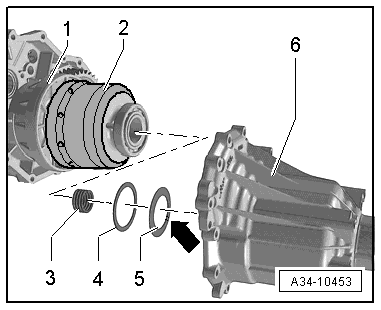

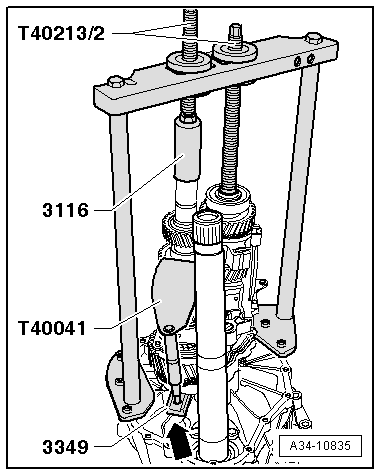

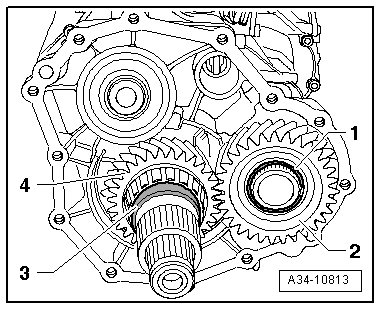

| The input shaft and output shaft must be pressed out together. |

| t

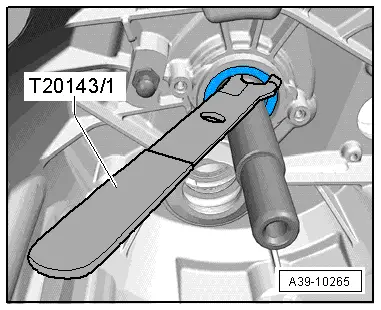

| It is permissible to turn the spindles alternately not more than one turn at a time when pressing out the shafts. |

| t

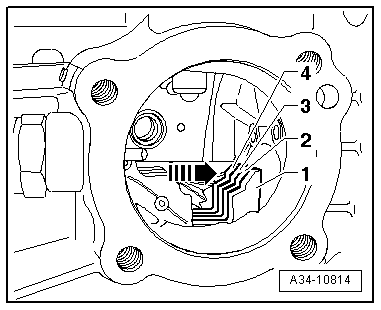

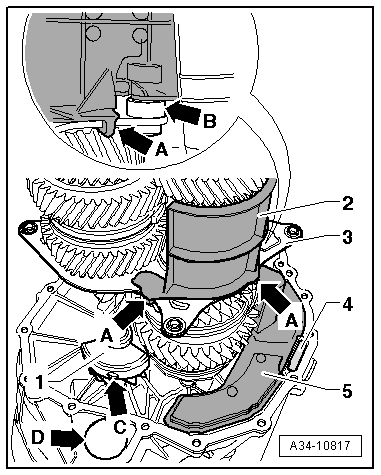

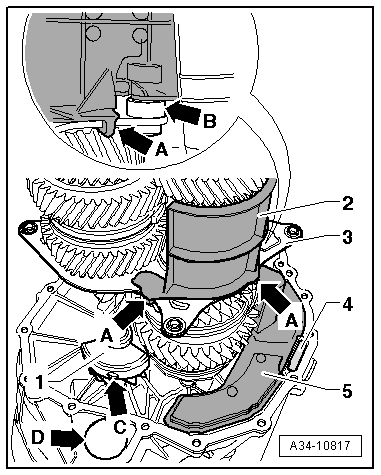

| Make sure the synchromesh for the reverse gear does not slip off the output shaft when taking out the gear cluster. |

|

| –

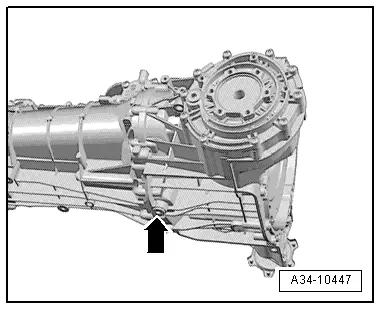

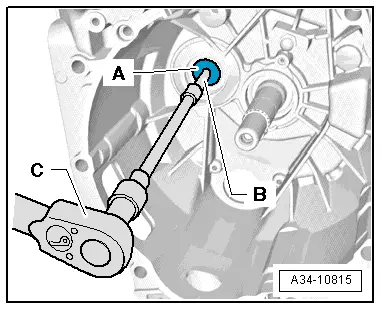

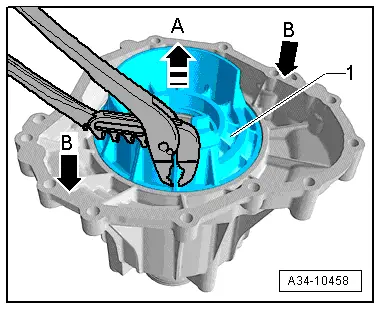

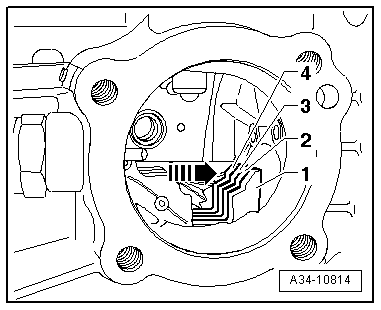

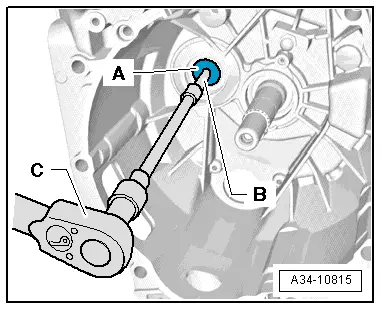

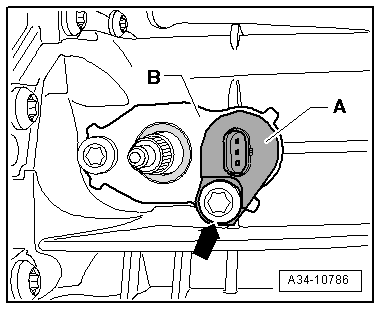

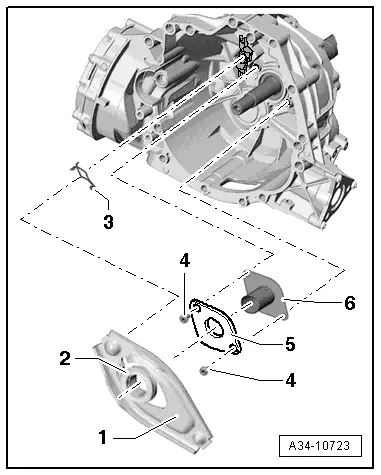

| By turning spindles of separating tool -T40213- alternately one turn at a time, press input shaft and output shaft out of ball bearings in gearbox housing. While doing so, make sure gear cluster does not drop (get help from a second person if necessary). |

| –

| Detach input shaft and output shaft together with selector fork cluster from gearbox housing. |

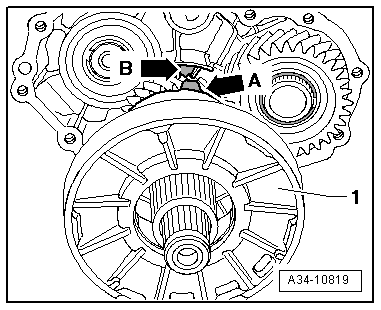

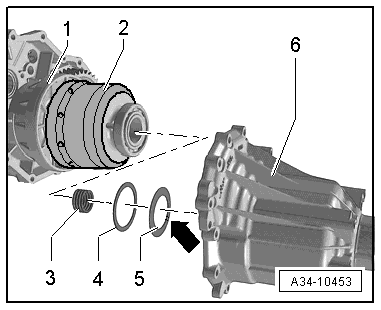

Note | If you are renewing the gearbox cover, spur gear drive input gear, tapered roller bearings for spur gear drive input gear, bearing plate or centre differential housing, you must first determine the thickness of the required shim for the preload of the tapered roller bearings for the spur gear drive input gear → Chapter. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Caution

Caution