| t

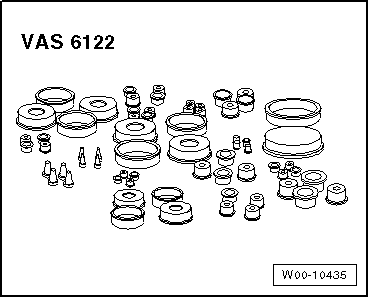

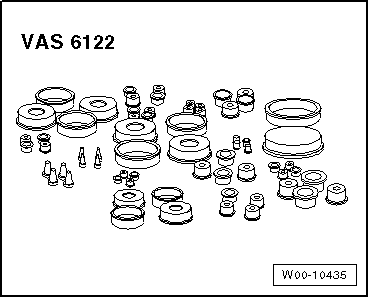

| Engine bung set -VAS 6122- |

WARNING | Make sure the vehicle cannot tip over when the engine is removed. |

| Secure the vehicle, to do so, the luggage compartment must be empty. |

|

Note | t

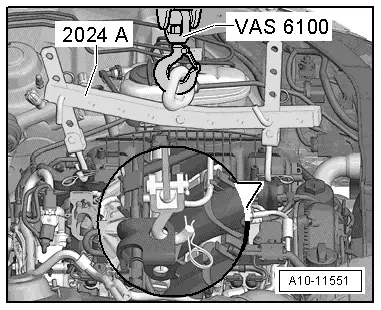

| Lift out engine without gearbox. |

| t

| Collect drained coolant in a clean container for re-use or disposal. |

| t

| Fit all cable ties in the original positions when installing. |

| t

| On four-wheel drive vehicles the electromechanical parking brake must be released before disconnecting the battery, so that the propshaft can be turned during removal. |

Caution | To prevent irreparable damage to the electronic components when disconnecting the battery: |

| Observe notes on procedure for disconnecting the battery → Rep. gr.27. |

|

| –

| Remove both front wheels. |

WARNING | Hot steam/hot coolant can escape - risk of scalding. |

| t

| The cooling system is under pressure when the engine is hot. |

| t

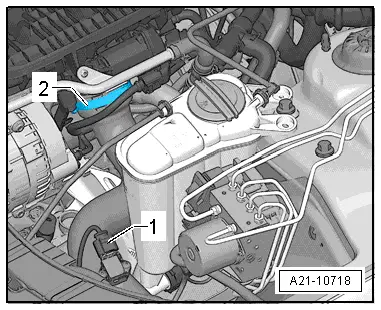

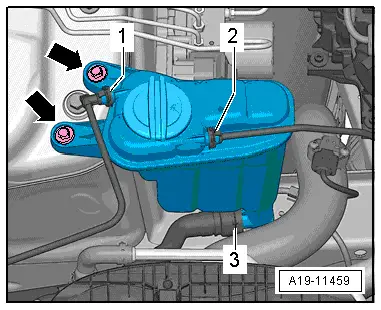

| To allow pressure to dissipate, cover filler cap on coolant expansion tank with cloth and open carefully. |

|

| –

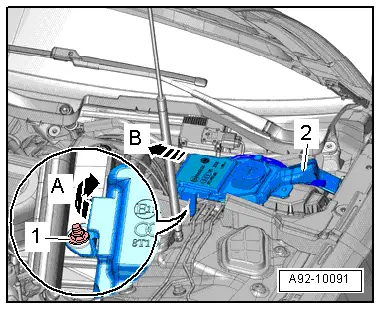

| Open filler cap on coolant expansion tank. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

WARNING

WARNING Caution

Caution