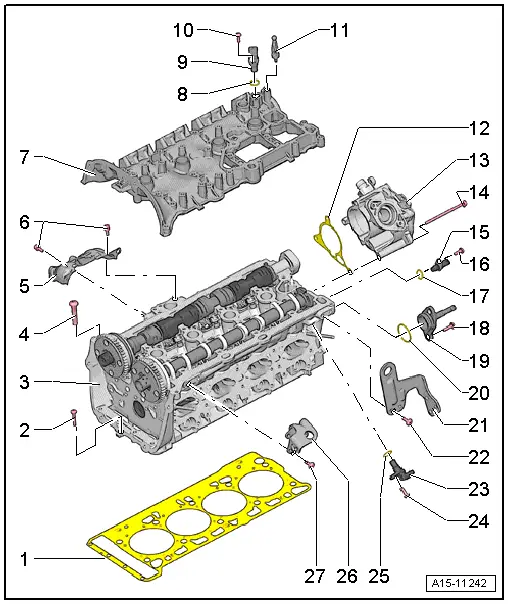

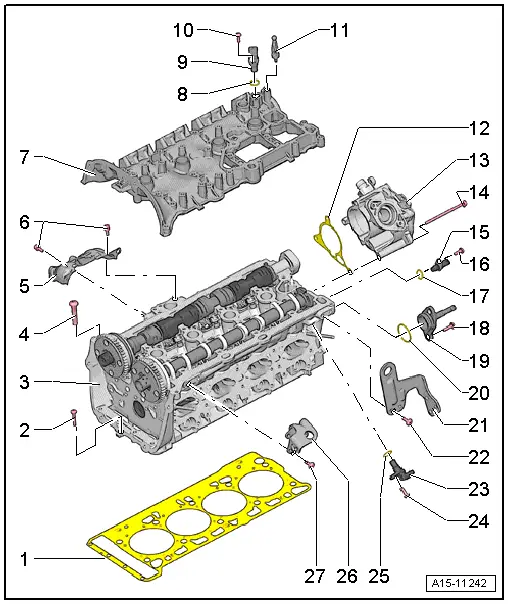

A4 Mk3 Power Unit: 4-Cylinder Direct Injection Engine Cylinder Head - Exploded View

| 1 - | Cylinder head gasket |

| q | Renew |

| q | Note installation position: part number must face cylinder head |

| 2 - | Bolt |

| q | Renew |

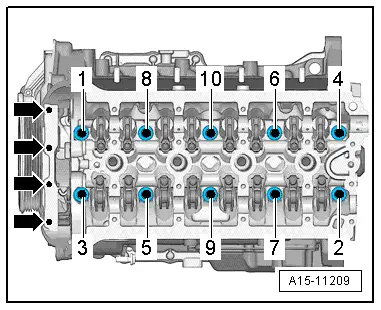

| q | Note procedure when loosening → Fig. |

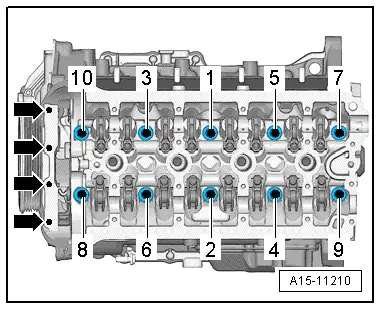

| q | Note procedure when tightening → Fig. |

| 3 - | Cylinder head |

| q | Removing and installing → Chapter |

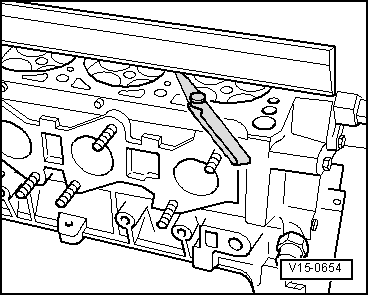

| q | Checking for distortion → Fig. |

| 4 - | Cylinder head bolt |

| q | Renew |

| q | Note procedure when loosening → Fig. |

| q | Note procedure when tightening → Fig. |

| 5 - | Heat shield |

| 6 - | Bolt |

| q | 9 Nm |

| 7 - | Cylinder head cover |

| q | With integrated camshaft bearings |

| q | Clean sealing surface; machining not permitted |

| q | Remove old sealant residues |

| 8 - | O-ring |

| q | Renew |

| q | Lubricate with engine oil |

| 9 - | Hall sender 3 -G300- |

| 10 - | Bolt |

| q | 9 Nm |

| 11 - | Sealing plug |

| q | 5 Nm |

| q | With ball head for engine cover panel |

| 12 - | Gasket |

| q | Renew if damaged |

| 13 - | Vacuum pump |

| q | Removing and installing → Rep. gr.47 |

| 14 - | Bolt |

| q | Tightening torque → Rep. gr.47 |

| 15 - | Coolant temperature sender -G62- |

| 16 - | Bolt |

| q | 9 Nm |

| 17 - | O-ring |

| q | Renew |

| q | Lubricate with coolant |

| 18 - | Bolt |

| q | 9 Nm |

| 19 - | Connection |

| 20 - | O-ring |

| q | Renew |

| q | Lubricate with coolant |

| 21 - | Transport plate |

| 22 - | Bolt |

| q | 25 Nm |

| 23 - | Hall sender -G40- |

| 24 - | Bolt |

| q | 9 Nm |

| 25 - | O-ring |

| q | Renew |

| q | Lubricate with engine oil |

| 26 - | Transport plate |

| 27 - | Bolt |

| q | 25 Nm |

|

|

|

|

|

|

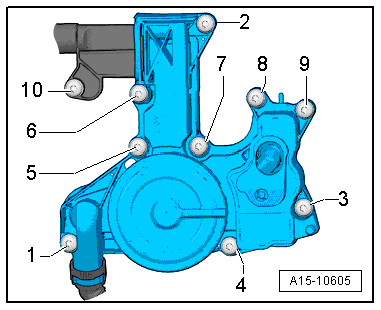

| 1 - | Cylinder head gasket |

| q | Renew |

| q | Note installation position: part number must face cylinder head |

| 2 - | Cylinder head bolt |

| q | Renew |

| q | Note procedure when loosening → Fig. |

| q | Note procedure when tightening → Fig. |

| 3 - | Sealing cap |

| q | With seal |

| 4 - | O-ring |

| q | Renew |

| q | Lubricate with engine oil |

| 5 - | Sealing plug |

| 6 - | Bolt |

| q | 20 Nm |

| 7 - | Bolt |

| q | 20 Nm |

| 8 - | Breather pipe |

| 9 - | Engine cover panel |

| 10 - | Bolt |

| q | Tightening sequence → Fig. |

| 11 - | Crankcase breather |

| 12 - | Gasket |

| q | Not available as replacement part |

| 13 - | Bracket |

| 14 - | Bolt |

| q | 9 Nm |

| 15 - | O-ring |

| q | Renew |

| q | Lubricate with coolant |

| 16 - | Bolt |

| q | 9 Nm |

| 17 - | Hall sender -G40- |

| 18 - | Separating plate |

| 19 - | O-ring |

| q | Renew |

| q | Lubricate with engine oil |

| 20 - | Actuator for variable valve timing |

| 21 - |

Note

Note

|

|