A4 Mk3

| Removing and installing camshafts |

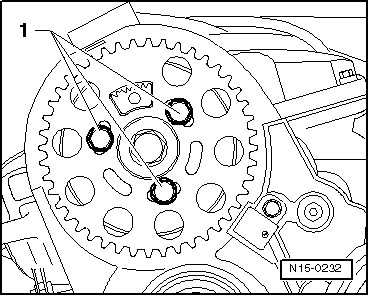

| t | Diesel injection pump locking pin -3359- |

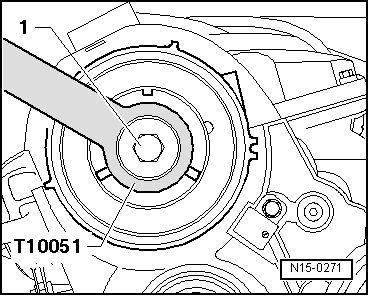

| t | Counterhold tool -T10051- |

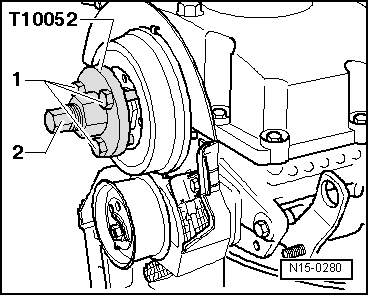

| t | Puller -T10052- |

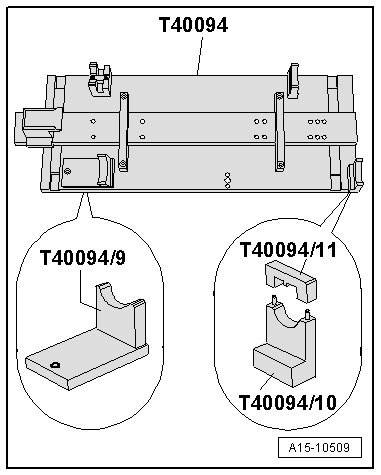

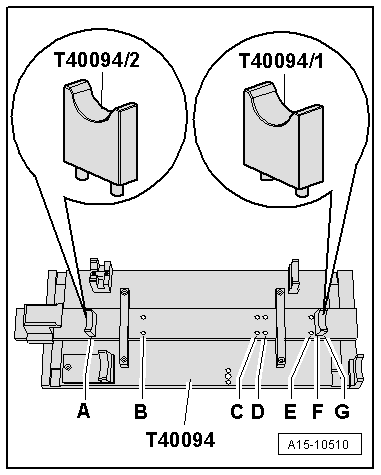

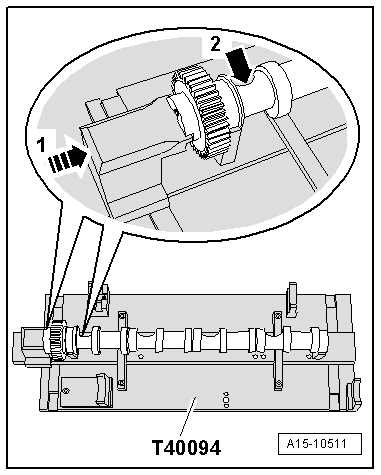

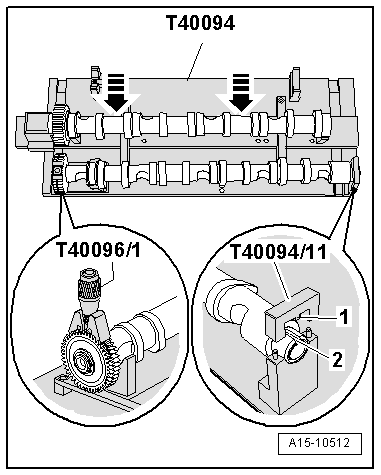

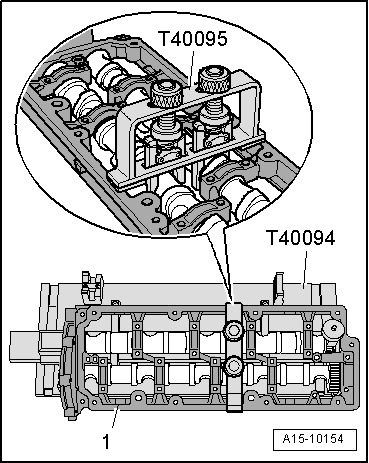

| t | Camshaft fitting tool -T40094- |

| t | Camshaft fitting tool -T40095- |

| t | Clamping tool -T40096/1- |

|

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

Note

Note

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note |

|

|

|

|

|

Caution

Caution WARNING

WARNING